Content .. 1229 1230 1231 1232 ..

Nissan Rogue. Manual - part 1231

WCS

THE KEY WARNING DOES NOT SOUND (WITHOUT INTELLIGENT KEY)

WCS-53

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

M

B

A

O

P

THE KEY WARNING DOES NOT SOUND (WITHOUT INTELLIGENT KEY)

Description

INFOID:0000000011276496

The key warning chime does not sound, when all of the following conditions are fulfilled:

• Key inserted into the key cylinder (key switch signal ON).

• Ignition switch is in OFF position (ignition switch signal OFF).

• Driver side door is open (front door switch LH ON)

Diagnosis Procedure

INFOID:0000000011276497

1.

CHECK BCM INPUT SIGNAL

1. Connect CONSULT.

2. Select the “Data Monitor” of “BCM (BUZZER)” and check the “KEY ON SW” monitor value.

Is the inspection result normal?

YES

>> Replace the BCM. Refer to

BCS-135, "Removal and Installation"

.

NO

>> GO TO 2.

2.

CHECK KEY SWITCH SIGNAL CIRCUIT

Check the key switch signal circuit. Refer to

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair or replace harness or connector.

3.

CHECK KEY SWITCH

Check the key switch. Refer to

WCS-48, "Component Inspection"

Is the inspection result normal?

YES

>> Replace the BCM. Refer to

BCS-135, "Removal and Installation"

.

NO

>> Replace key switch. Refer to

SEC-195, "Removal and Installation"

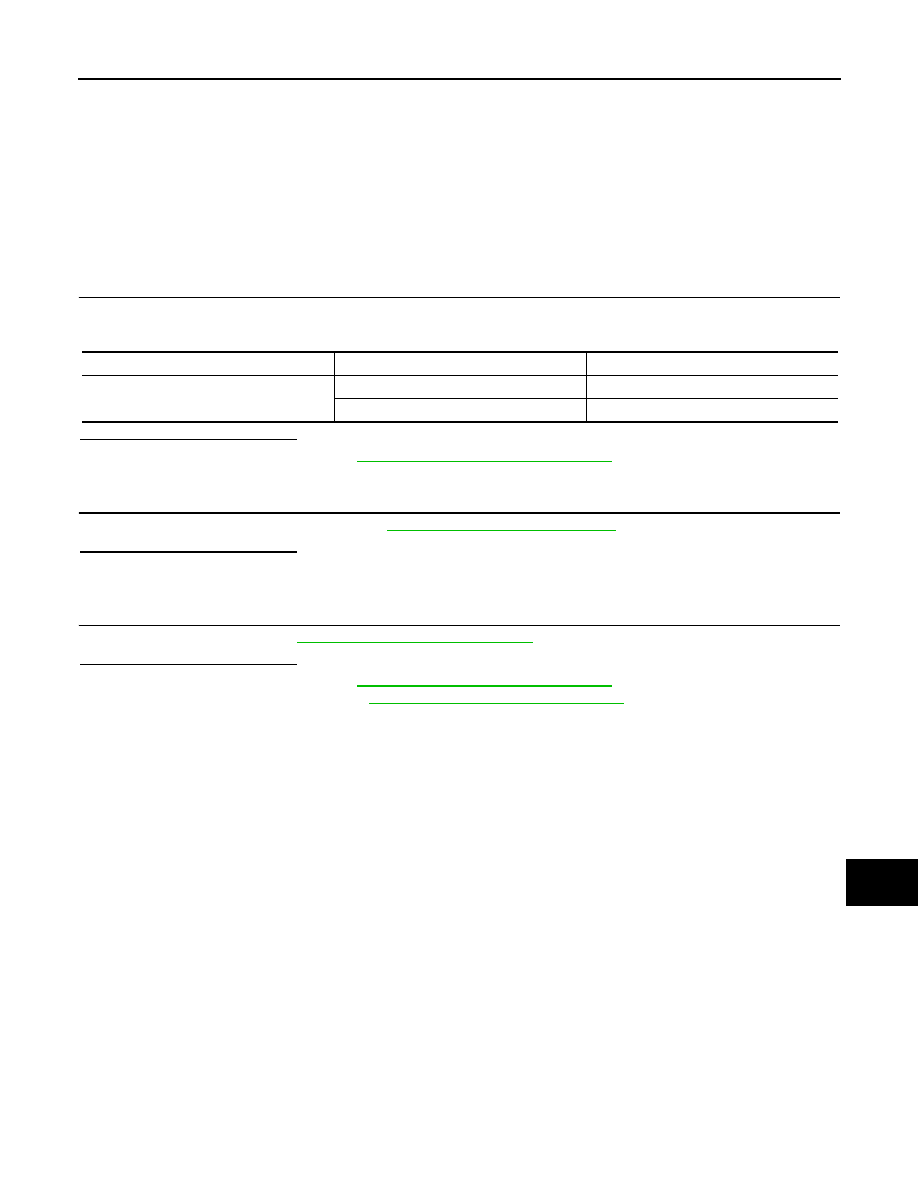

Monitor item

Condition

Status

KEY ON SW

Under the condition of buzzer input

On

Except above

Off