Nissan Maxima. Manual - part 214

BCS

DIAGNOSIS AND REPAIR WORKFLOW

BCS-3

< BASIC INSPECTION >

[BCM]

C

D

E

F

G

H

I

J

K

L

B

A

O

P

N

BASIC INSPECTION

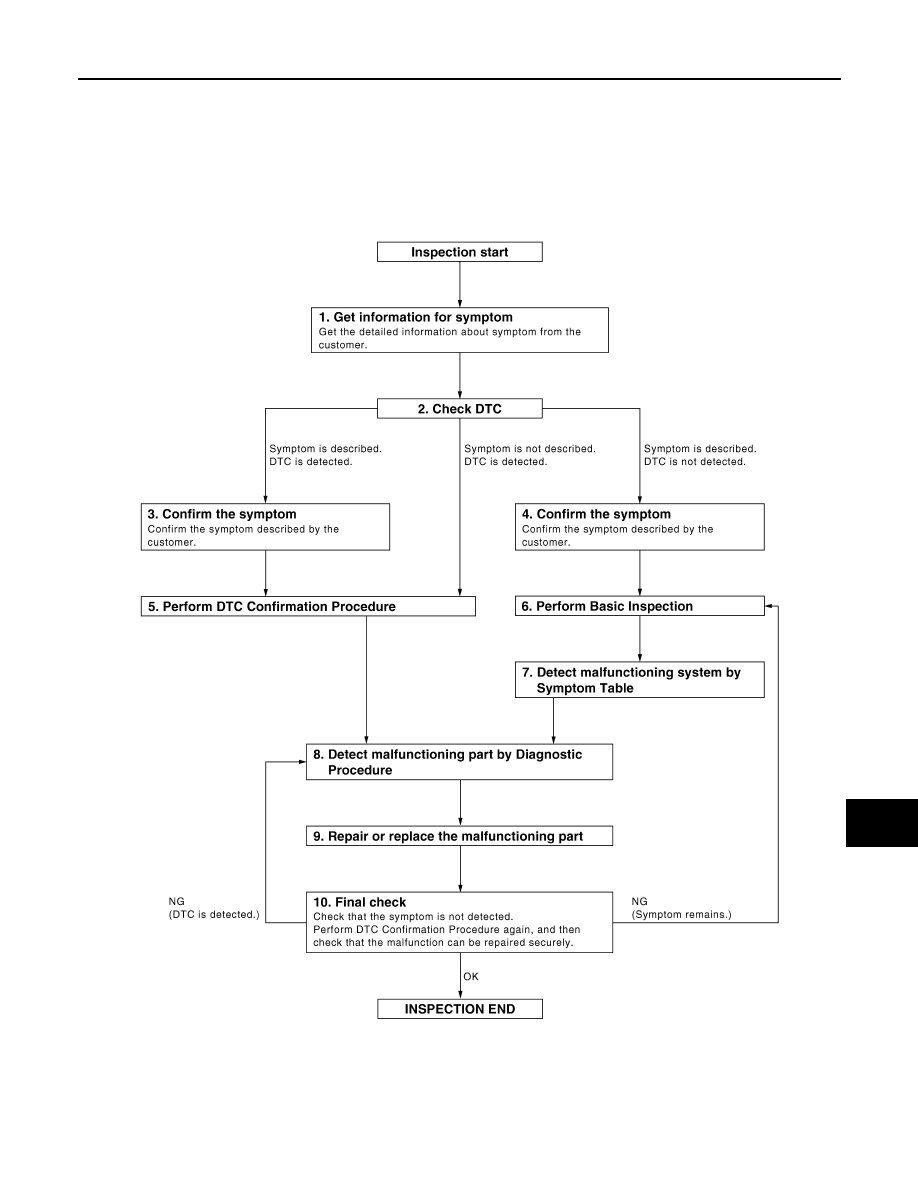

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

INFOID:0000000009467024

OVERALL SEQUENCE

DETAILED FLOW

JMKIA0101GB