Content .. 1182 1183 1184 1185 ..

Nissan Pathfinder. Manual - part 1184

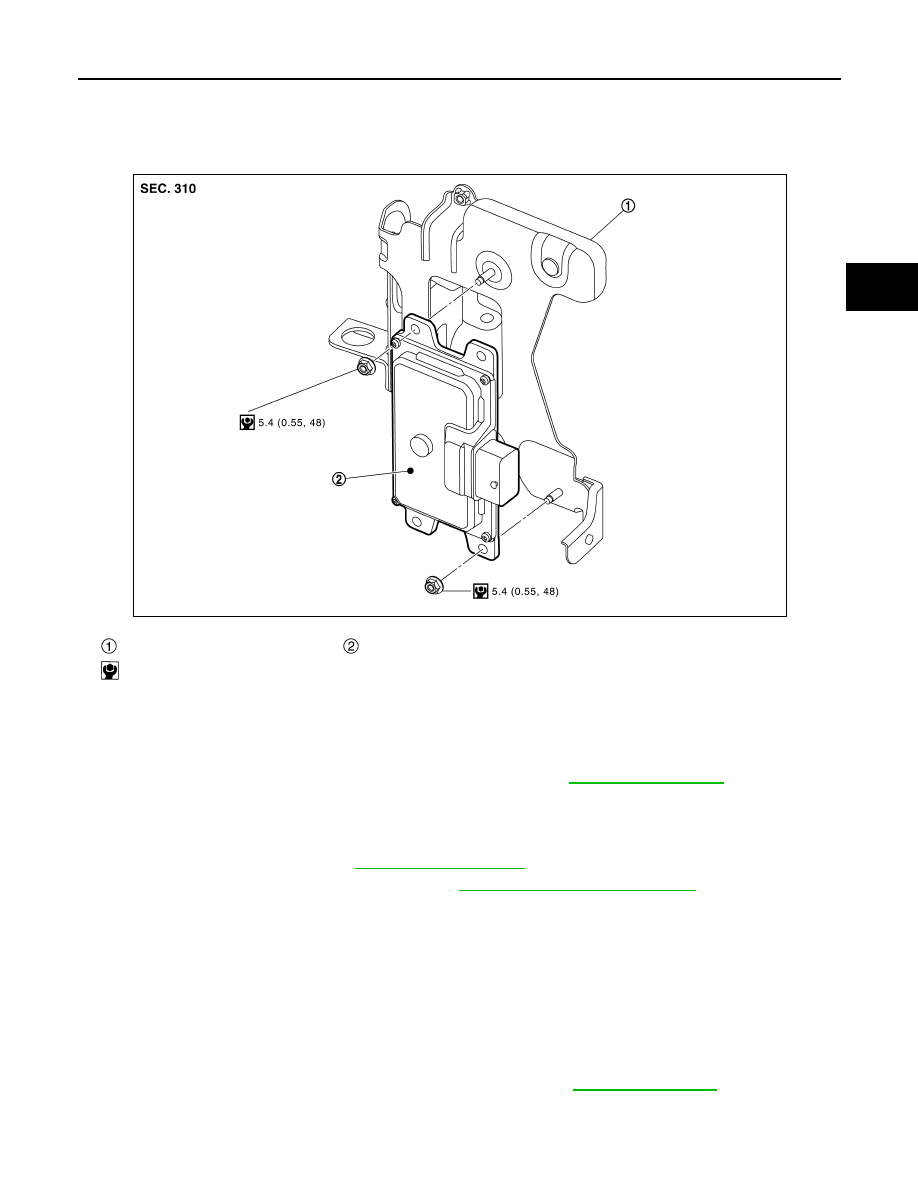

TCM

TM-195

< REMOVAL AND INSTALLATION >

[CVT: RE0F10E]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

TCM

Exploded View

INFOID:0000000009177653

Removal and Installation

INFOID:0000000009177654

CAUTION:

• To replace TCM, perform " WRITE IP CHARA – REPLACEMENT TCM" of the CONSULT Work Support

before removing TCM and save TCM data in CONSULT. Refer to

• When replacing TCM, note the “CVTF DETERIORATION DATE” value displayed on CONSULT “CON-

FORM CVTF DETERIORTN” in MAINTENANCE BOOKLET, before start the operation.

REMOVAL

1. Remove the front air duct. Refer to

2. Disconnect the negative battery terminal. Refer to

PG-90, "Removal and Installation"

3. Disconnect the TCM harness connector.

4. Remove the TCM and bracket as a set.

5. Remove the TCM from the bracket.

INSTALLATION

Installation is the reverse order of removal.

Adjustment

INFOID:0000000009177655

ADJUSTMENT AFTER INSTALLATION

Perform "ADDITIONAL SERVICE WHEN REPLACING TCM". Refer to

.

Bracket

TCM

: N·m (kg-m, in-lb)

JSDIA3618GB