Nissan Qashqai J11. Manual - part 855

FSU-10

< REMOVAL AND INSTALLATION >

FRONT COIL SPRING AND STRUT

Removal and Installation

INFOID:0000000010297071

REMOVAL

1.

Remove tires from vehicle.

2.

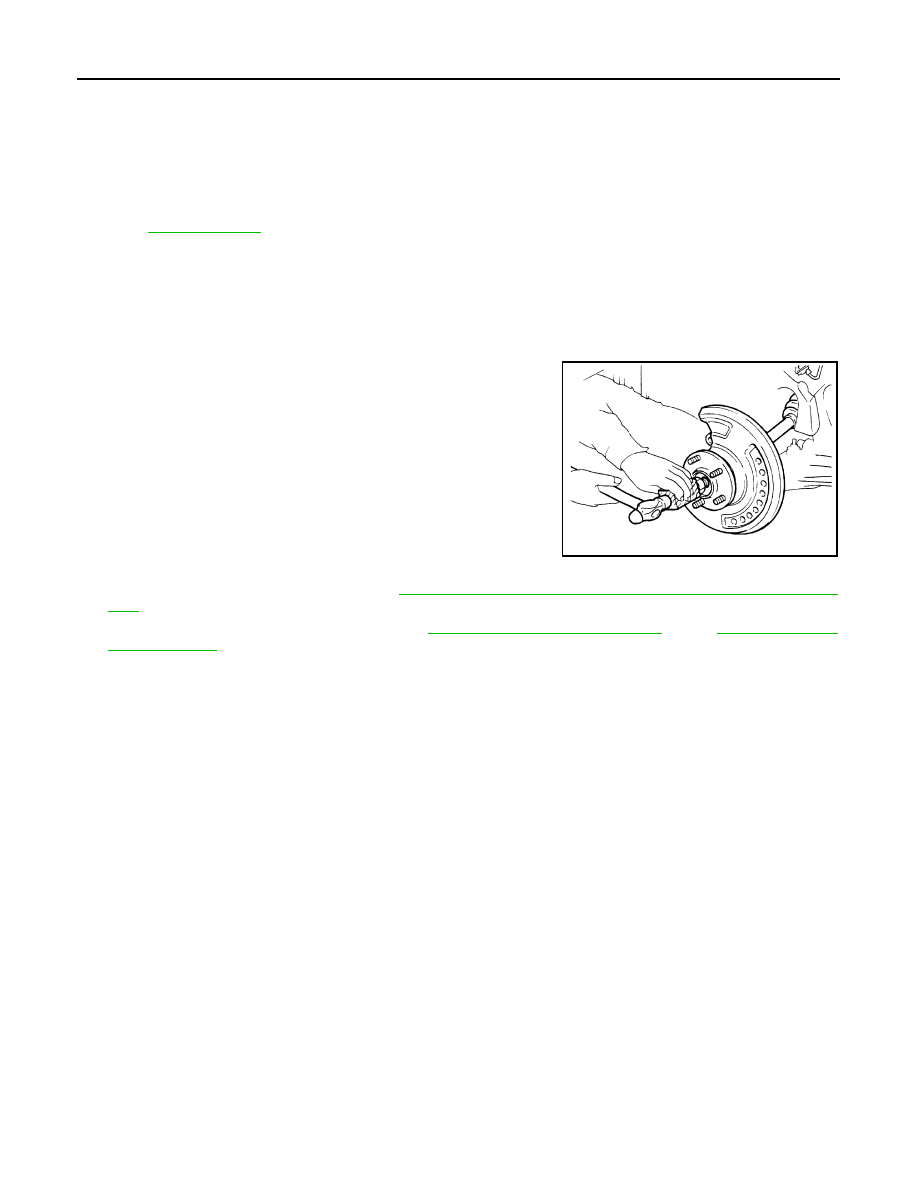

Remove wheel hub lock nut.

3.

Tap wheel hub lock nut with a piece of wood to disengage wheel

hub and bearing from drive shaft.

NOTE:

Use a suitable puller if wheel hub and bearing and drive shaft

cannot be separated even after performing the above proce-

dure.

4.

Remove brake rotor and caliper. Refer to

BR-37, "BRAKE CALIPER ASSEMBLY : Removal and Installa-

5.

Remove the brake hose lock plate from strut.

BR-19, "FRONT : Exploded View"

(RHD).

6.

Remove the bolt and separate the front wheel sensor from the steering knuckle. Separate the harness

from the brackets and position aside.

CAUTION:

• Failure to separate the front wheel sensor from the steering knuckle may result in damage to the

front wheel sensor.

• Pull out the front wheel sensor, being careful to turn it as little as possible. Do not pull on wheel

sensor harness.

7.

Remove the nut and separate the stabilizer connecting rod from the strut bracket.

8.

Separate axle transverse link and steering knuckle.

9.

Remove front strut lower bolt.

1.

Strut mounting insulator

2.

Strut mounting bearing

3.

Bound bumper

4.

Coil spring

5.

Lower rubber seat

6.

Strut

7.

Steering knuckle

8.

Stabilizer connecting rod

9.

Stabilizer clamp

10. Stabilizer bushing

11. Stabilizer bar

12. Front suspension member

13. Rebound stopper rubber

14. Front suspension member stay

15. Transverse link

16. Rear suspension member stay

17. Front suspension member insulator

Refer to

for symbols in the figure.

JPDIG0070ZZ