Mitsubishi Lancer Evolution 8 MR. Manual - part 10

3-2

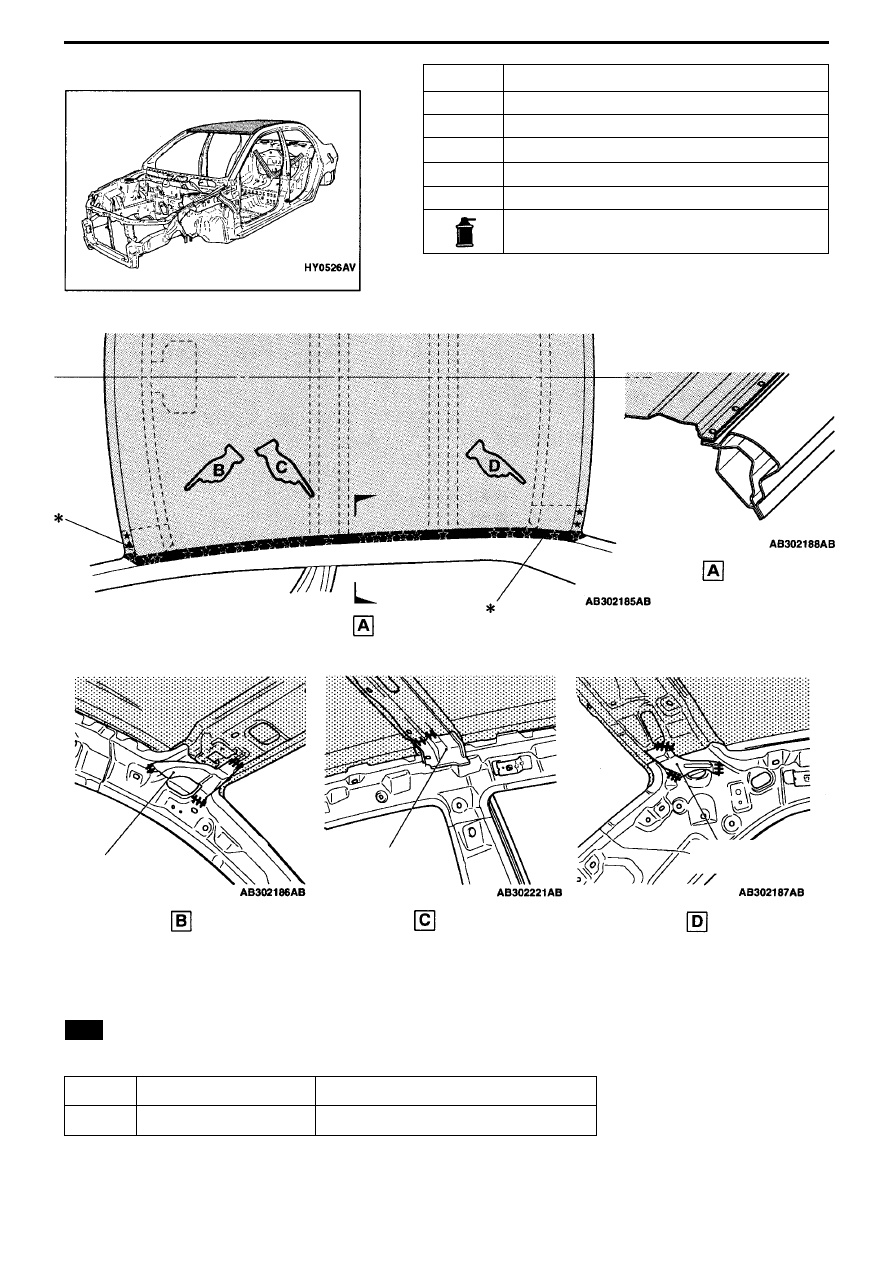

CHANGING WELDED PANELS – ROOF

Symbol

Operation details

● ● ● ●

Spot welding

■ ■ ▲ ▲

MIG plug welding (

■

: two layers

▲

: three layers)

+ + + +

MIG spot welding

✝✝✝✝✝✝✝✝

MIG arc welding (continuous)

★ ★ ★ ★

Rivet

Areas where rust inhibitor is applied. (Applied using

holes in butt welded locations)

Front pillar

upper support

Centre pillar

upper support

Rear pillar upper

support

Note

❉

: these welding points are done by manufacturer (not necessary during repairs).

:

black shading indicates areas where structural adhesive is applied.

Adhesive Type

Product name

Epoxy structural adhesive Sumitomo 3M Auto Mix Panel Bond 8115

SERVICE JOINTS