Mazda 6. Manual - part 177

F–230

TROUBLESHOOTING

7. Verify that the engine speed is within the specification under each load condition.

• If not as specified specific load condition, inspect the following.

— A/C switch and related harness

(See

U–47 CLIMATE CONTROL UNIT INSPECTION

.)

— Fan switch and related harness

(See

U–47 CLIMATE CONTROL UNIT INSPECTION

.)

— PSP switch and related harness

(See

F–58 POWER STEERING PRESSURE (PSP) SWITCH INSPECTION

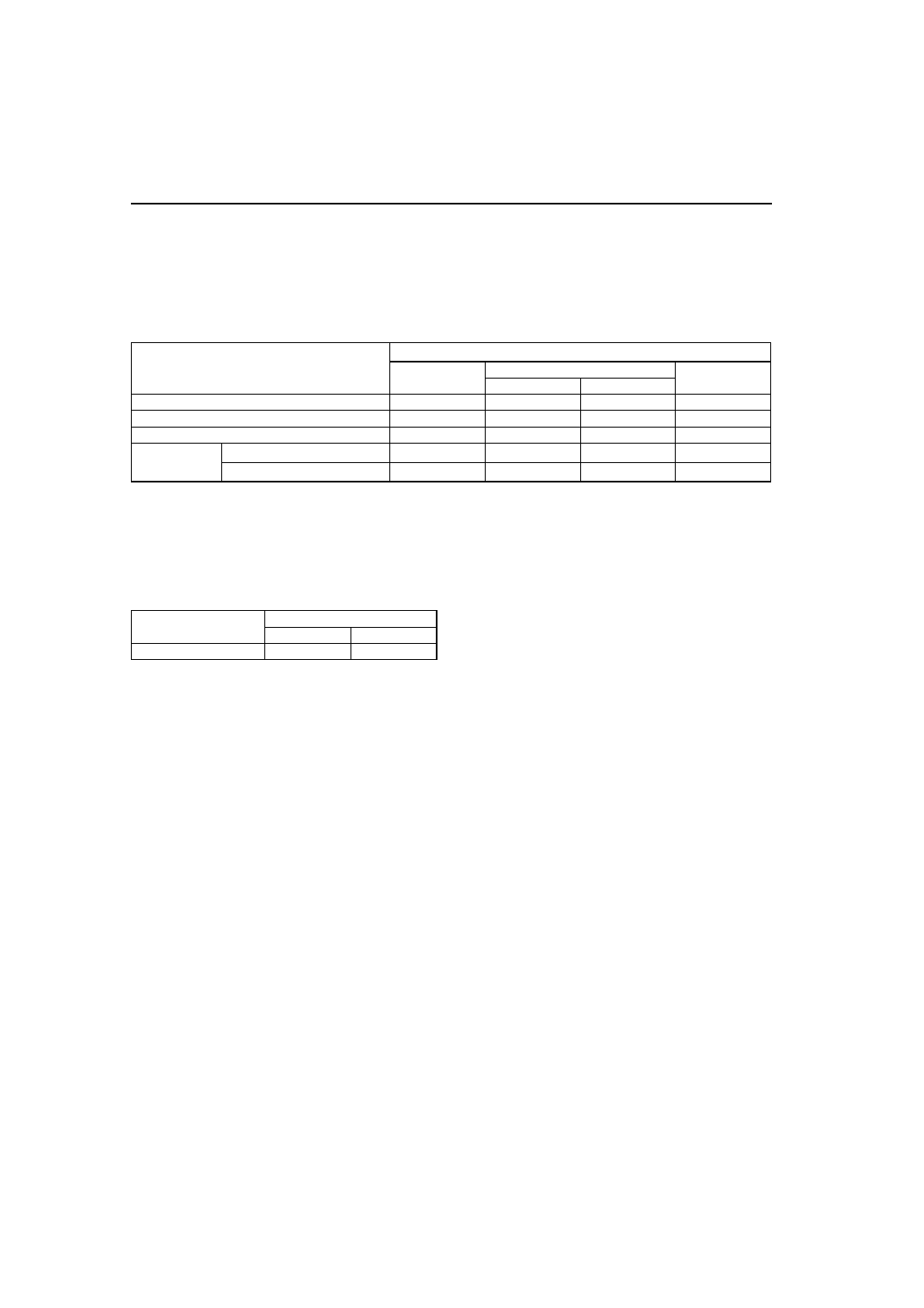

Engine speed

*1

: Neutral or P position

*2

: A/C switch and fan switch are on.

*3

: Refrigerant pressure switch (middle pressure) is off.

*4

: Refrigerant pressure switch (middle pressure) is on.

VIS Operation Inspection

1. Start the engine.

2. Inspect the rod operation under the following condition.

Rod operation

• If the rod operation is not as specified, inspect as follows.

(1) Stop the engine.

(2) Connect WDS or equivalent to the DLC-2.

(3) Verify that DTC P0661 or P0662 is not displayed.

• If DTC P0661 or P0662 is shown, carry out DTC inspection.

(See

(4) Turn ignition switch to ON.

(5) Turn the VIS control solenoid valve from on to off using the IVC PID and verify that operation sound of the

solenoid valve is heard.

• If the operation sound is heard, inspect the following.

— Vacuum hose and vacuum chamber for looseness or damage

— Shutter valve actuator

(See

F–14 VARIABLE INTAKE-AIR SYSTEM (VIS) SHUTTER VALVE ACTUATOR INSPECTION

— Shutter valve stuck open or close

• If the operation sound is not heard, inspect the following.

— VIS control solenoid valve

(See

F–14 VARIABLE INTAKE-AIR SYSTEM (VIS) CONTROL SOLENOID VALVE INSPECTION

Load condition

Engine speed (rpm)

*1

L8

LF

L3

MTX

ATX

No load

650—750

600—700

650—750

600—700

E/L operating

650—750

650—750

650—750

650—750

P/S operating

700—800

650—750

650—750

650—750

A/C operating

*2

Refrigerant pressure low

*3

700—800

700—800

650—750

700—800

Refrigerant pressure high

*4

700—800

700—800

700—800

700—800

Engine speed

Approx. 4,400 rpm

Below

Above

Shutter valve actuator

Operate

Not operate