Mazda Protege 5. Manual - part 354

INSTRUMENTATION/DRIVER INFO.

09–22–10

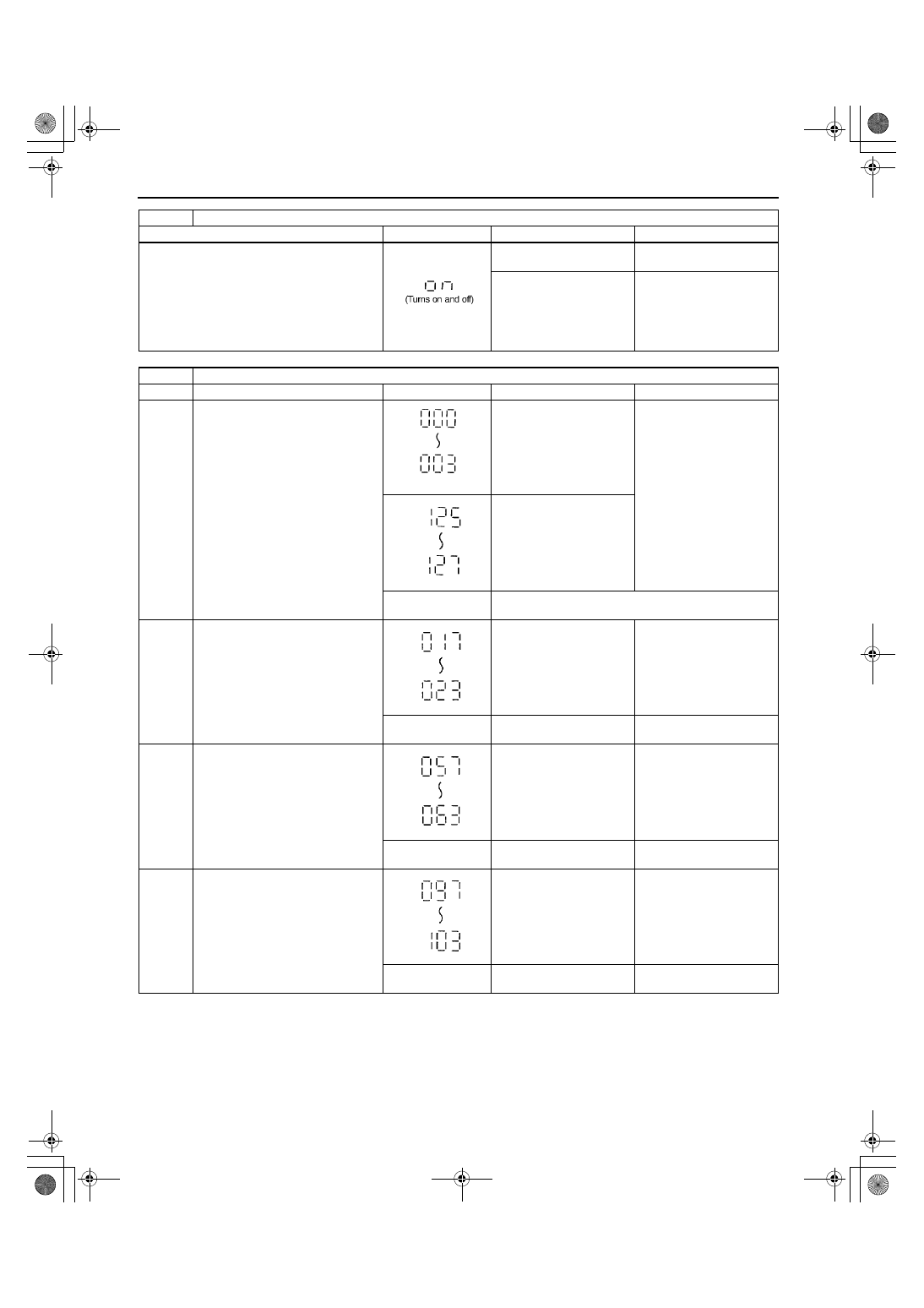

DTC 16

Operation signal to fuel-level warning light

INSPECTION

INDICATION

SITUATION

ACTION

Wait for 2 seconds after selecting DTC 16.

Fuel-level warning light

turns on and off 3 times.

Fuel-level warning light is

okay.

Other than stated above.

Inspect fuel-level warning

light.

(See 09–22–13 WARNING

AND INDICATOR LIGHT

BULB REMOVAL/

INSTALLATION)

DTC 22

Fuel level signal

STEP

INSPECTION

INDICATION

SITUATION

ACTION

1

Select DTC 22.

Short to GND.

•

Inspect fuel gauge

sender unit.

(See 09–22–13 FUEL

GAUGE SENDER

UNIT INSPECTION)

•

Inspect wiring harness.

(Instrument cluster —

fuel gauge sender

unit.)

Open circuit.

Other than stated

above.

Go to next step.

2

Using SST (Fuel And Thermometer

checker), input 20 ohms to terminal

3C of instrument cluster.

—

Go to next step.

Other than stated

above.

—

Replace instrument

cluster.

3

Using SST (Fuel And Thermometer

checker), input 60 ohms to terminal

3C of instrument cluster.

—

Go to next step.

Other than stated

above.

—

Replace instrument

cluster.

4

Using SST (Fuel And Thermometer

checker), input 100 ohms to

terminal 3C of instrument cluster.

—

Input signal to instrument

cluster is okay.

Other than stated

above.

—

Replace instrument

cluster.

1712-1U-01G(09-22).fm 10 ページ 2001年6月29日 金曜日 午前10時39分