Mazda Protege 5. Manual - part 114

SYMPTOM TROUBLESHOOTING [ENGINE CONTROL SYSTEM (FS)]

01–03B–49

01–03B

End Of Sie

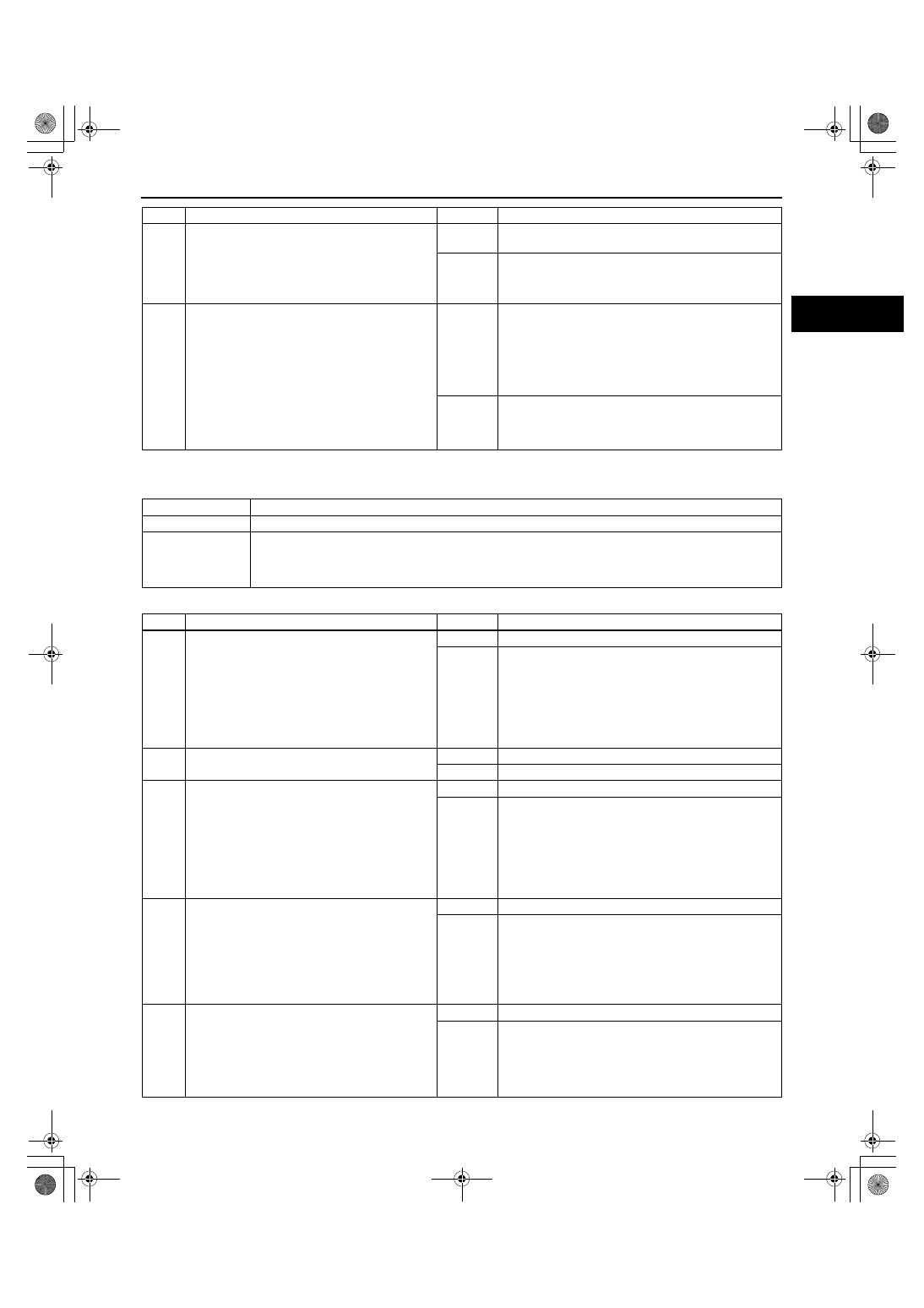

NO.30 REFERENCE VOLTAGE [FS]

A3U010318881W35

Diagnostic procedure

3

•

Start engine.

•

Lightly tap on suspect component, wiggle

and pull each wire/connector at suspect

component or PCM.

•

Are any PID values out of range, or do they

suddenly change and go back into range?

Yes

Inspect each wire for corrosion, bent or loose terminal

crimps.

No

Go to next step.

4

•

Start engine.

•

Accurately spray water on suspect

component wire, component or vacuum line

related to possible fault area.

•

Are any PID values out of range, or suddenly

change and go back into range, or was there

a noticeable engine misfire/stumble?

Yes

Fault occurred while spraying on component:

•

Replace part and verify repair.

Fault occurred while spraying wiring:

•

Inspect each wire for corrosion, bent or loose

terminals and poor wire terminal crimps.

Fault occurred while spraying vacuum line:

•

Repair vacuum hoses.

No

Inspect wire and connector at suspect component for

corrosion, bent or loose terminals, poor wire terminal

crimps and high tension of wire.

Repair as necessary.

STEP

INSPECTION

RESULTS

ACTION

30

Reference voltage

DESCRIPTION

•

Incorrect reference voltage

POSSIBLE CAUSE

•

Reference voltage circuit malfunction

Note

•

TP sensor, EGR boost sensor and fuel tank pressure sensor use reference voltage.

STEP

INSPECTION

RESULTS

ACTION

1

•

Disconnect appropriate sensor connector

when reference voltage circuit inspection

failed.

•

Turn ignition key to ON.

•

Measure voltage between following

appropriate sensor connector terminals:

— Reference voltage terminal — GND

terminal

•

Is reference voltage greater than 6.0 V?

Yes

Go to Step 13.

No

Go to next step.

2

•

Is voltage across battery terminals greater

than 10.5 V?

Yes

Go to next step.

No

Inspect charging system.

3

•

Turn ignition key to LOCK.

•

Leave appropriate sensor connector

disconnected.

•

Measure voltage between battery positive

terminal and GND (between PCM and

appropriate sensor) circuit at appropriate

sensor connector.

•

Is voltage greater than 10.5 V and within

1.0 V of battery voltage?

Yes

Go to next step.

No

Go to Step 8.

4

Note

•

The purpose of this step is to determine if

WDS or equivalent is communicating with

PCM.

•

Turn ignition key to ON.

•

Attempt to access ECT PID.

•

Can ECT PID be accessed?

Yes

Go to Step 7.

No

Go to next step.

5

•

Turn ignition key to LOCK.

•

Disconnect TP sensor, EGR boost sensor,

FTP sensor and PCM connectors.

•

Turn ignition key to ON.

•

Measure voltage between PCM connector

terminals 71/97 and 24/51/76/77/103.

•

Is voltage greater than 10.5 V?

Yes

Go to next step.

No

Repair open circuit between PCM terminal 71/97 and

main relay.

1712-1U-01G(01-03B).fm 49 ページ 2001年6月29日 金曜日 午前9時33分