Mazda Protege 5. Manual - part 115

SYMPTOM TROUBLESHOOTING [ENGINE CONTROL SYSTEM (FS)]

01–03B–53

01–03B

End Of Sie

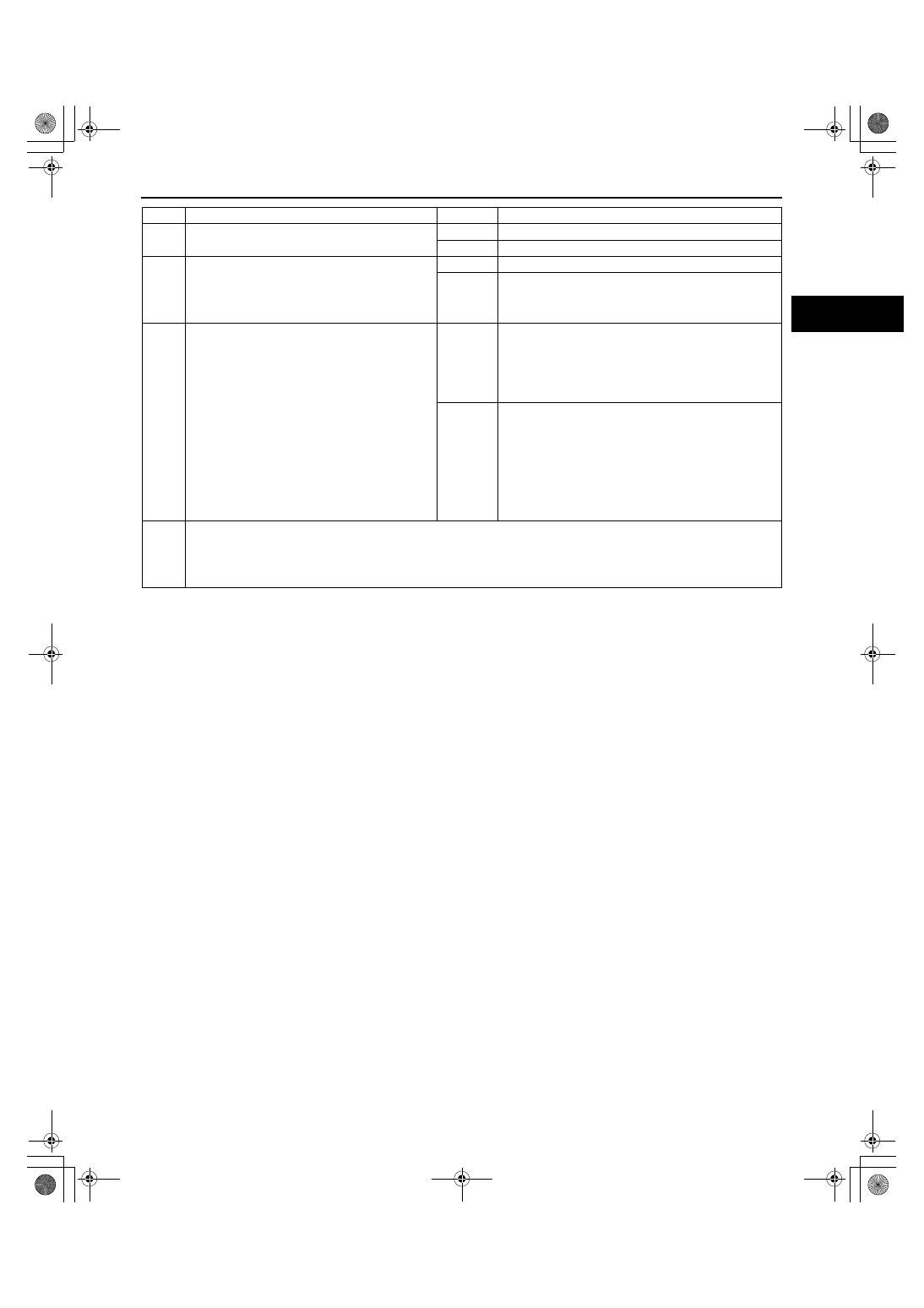

14

•

Carry out compression inspection.

•

Is compression correct?

Yes

Inspect for clogging in exhaust system.

No

Repair or replace malfunctioning part.

15

•

When engine cannot be started, inspect

intake-air system for air leakage.

•

When engine can be started, carry out intake

manifold vacuum inspection.

•

Is air sucked in from intake-air system?

Yes

Repair or replace malfunctioning part.

No

Go to next step.

16

•

Carry out fuel line pressure inspection.

•

Is fuel line pressure correct?

Fuel line pressure

260—310 kPa {2.6—3.2 kgf/cm

2

, 37—45 psi}

Yes

Inspect following PIDs.

•

ECT

•

O2S11

•

O2S12

•

MAF

Inspect PCM GND condition.

No

Zero or low:

•

Inspect fuel pump circuit.

•

Inspect open for fuel pump relief valve.

•

Inspect for fuel leakage inside pressure regulator.

•

Inspect for clogged main fuel line.

•

Inspect pulsation damper.

High:

•

Inspect pressure regulator for high pressure cause.

•

Inspect for clogged fuel return line.

17

•

Verify test results.

— If okay, return to diagnostic index to service any additional symptoms.

— If malfunction remains, inspect related Service Bulletins and perform repair or diagnosis.

•

If vehicle is repaired, troubleshooting is completed.

•

If vehicle is not repaired or additional diagnostic information is not available, replace PCM.

STEP

INSPECTION

RESULTS

ACTION

1712-1U-01G(01-03B).fm 53 ページ 2001年6月29日 金曜日 午前9時33分