Mazda Protege 5. Manual - part 31

ON-BOARD DIAGNOSTIC [ENGINE CONTROL SYSTEM (ZM)]

01–02A–90

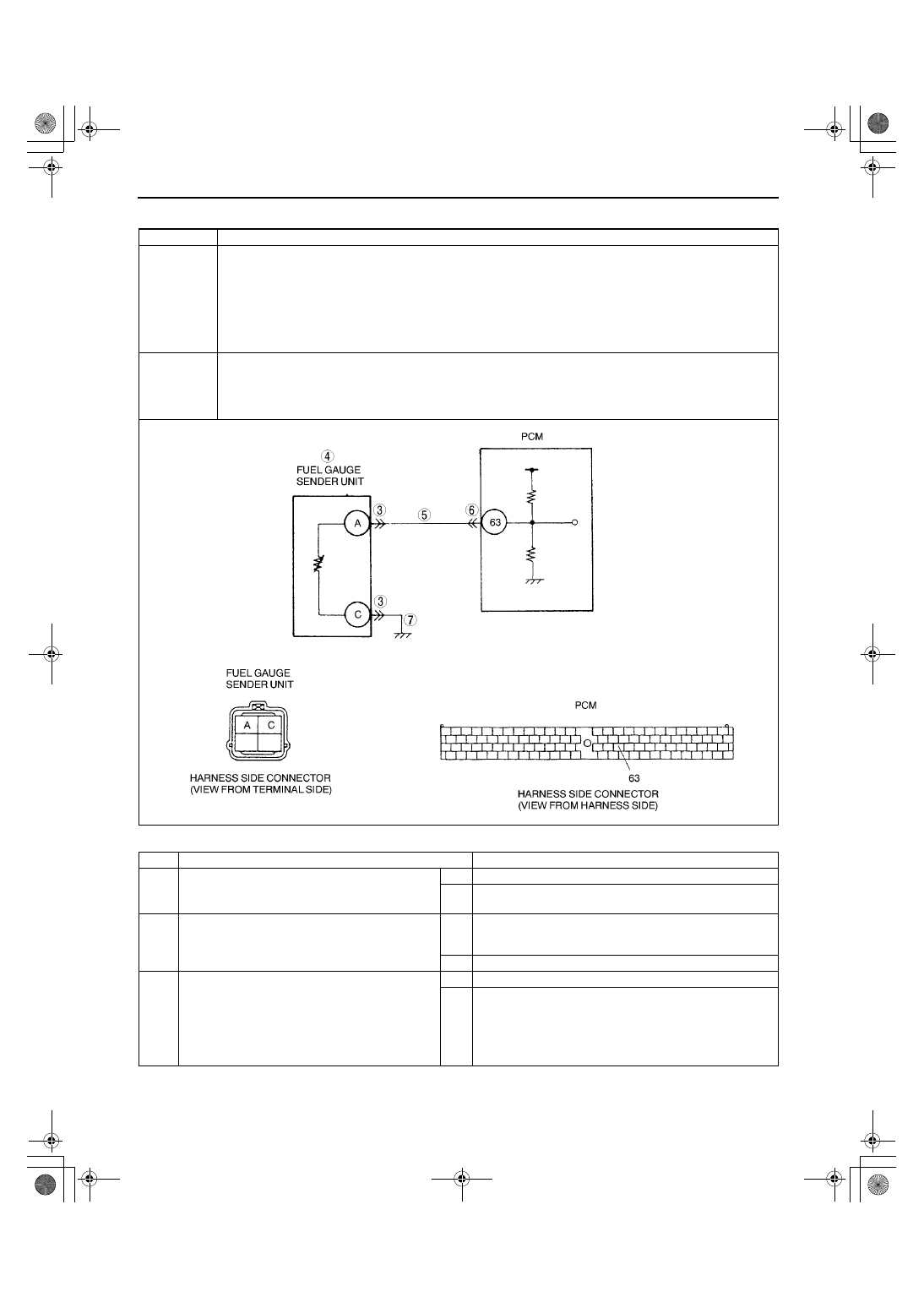

DTC P0463 [ZM]

A3U010201086W27

Diagnostic procedure

DTC P0463

Fuel gauge sender unit circuit high input

DETECTION

CONDITION

•

PCM monitors the voltage of fuel gauge sender unit. If PCM detects PCM terminal 63 voltage above 4.92

V for 5 seconds, PCM determines that fuel gauge sender unit circuit has a malfunction.

Diagnostic support note

•

This is a continuous monitor (CCM).

•

MIL illuminates if PCM detects the above malfunction condition in two consecutive drive cycles.

•

PENDING CODE is available if PCM detects the above malfunction condition during first drive cycle.

•

FREEZE FRAME DATA is available.

•

DTC is stored in PCM memory.

POSSIBLE

CAUSE

•

Fuel gauge sender unit malfunction

•

Open circuit between fuel gauge sender unit terminal A and PCM terminal 63.

•

Open circuit between fuel gauge sender unit terminal C and body ground.

•

Poor connection of fuel gauge sender unit and/or PCM connector

•

PCM malfunction

STEP

INSPECTION

ACTION

1

VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

•

Has FREEZE FRAME DATA been recorded?

Yes Go to next step.

No

Record FREEZE FRAME DATA on repair order, then go to

next step.

2

VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•

Check for related Service Bulletins availability.

•

Is any related repair information available?

Yes Perform repair or diagnosis according to available repair

information.

•

If vehicle is not repaired, go to next step.

No

Go to next step.

3

INSPECT FUEL GAUGE SENDER UNIT

CONNECTOR FOR POOR CONNECTION

•

Turn ignition key to OFF.

•

Disconnect fuel gauge sender unit connector.

•

Check for poor connection (damaged/pulled-

out terminals, corrosion, etc.).

•

Is there malfunction?

Yes Repair suspected terminal, then go to Step 8.

No

Go to next step.

1712-1U-01G(01-02A).fm 90 ページ 2001年6月29日 金曜日 午後2時20分