Mazda Protege 5. Manual - part 30

ON-BOARD DIAGNOSTIC [ENGINE CONTROL SYSTEM (ZM)]

01–02A–86

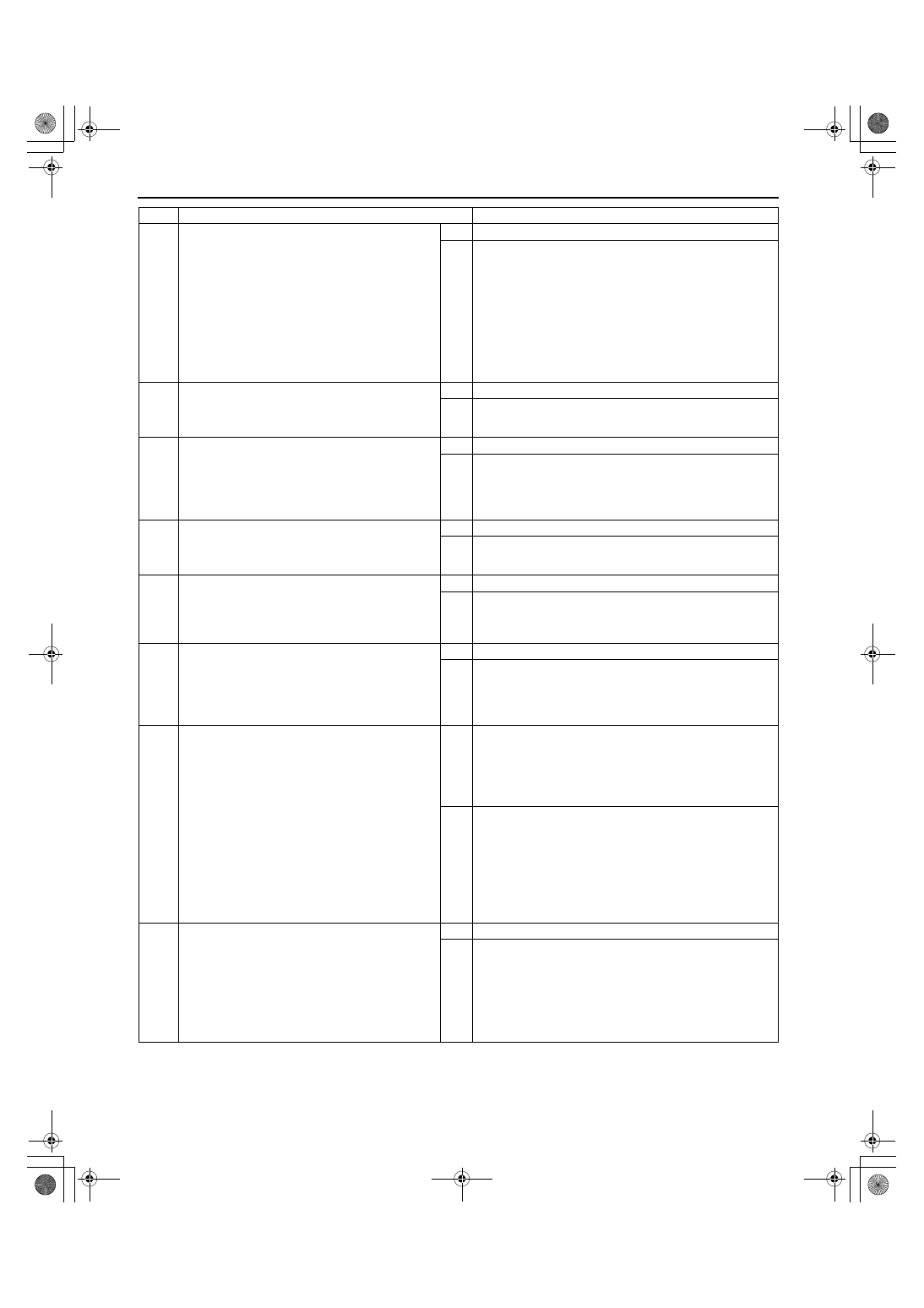

22

INSPECT LEAKAGE FROM CHARCOAL

CANISTER TO PURGE SOLENOID VALVE

•

Implement “01-03A ENGINE CONTROL

SYSTEM OPERATION INSPECTION [ZM],

Evaporative Leak System Inspection Using

Vacuum Pump, Inspection from charcoal

canister to purge solenoid valve”.

(See 01–03A–56 Inspection from charcoal

canister to purge solenoid valve.)

•

Does voltage change under to specified

readings and hold for a minimum of 2

minutes?

Yes Go to Step 27.

No

Go to next step.

23

INSPECT CATCH TANK

•

Remove catch tank and inspect for plugging,

damages and pinhole using vacuum pump.

•

Is it okay?

Yes Go to next step.

No

Replace catch tank, then go to Step 27.

24

INSPECT PURGE SOLENOID VALVE

OPERATION

•

Inspect purge solenoid valve

(See 01–16–12 PURGE SOLENOID VALVE

INSPECTION.)

•

Is purge solenoid valve okay?

Yes Go to next step.

No

Replace purge solenoid valve, then go to Step 27.

25

INSPECT CHARCOAL CANISTER

•

Remove charcoal canister and inspect for

plugging, damage and pinhole.

•

Is it okay?

Yes Go to next step.

No

Replace charcoal canister, then go to Step 27.

26

INSPECT CDCV OPERATION

•

Inspect CDCV.

(See 01–16–10 CANISTER DRAIN CUT

VALVE (CDCV) INSPECTION.)

•

Is CDCV okay?

Yes Go to next step.

No

Replace CDCV, then go to next step.

27

DECIDE ON AFTER REPAIR PROCEDURE

ACCORDING TO REPAIR SHOP CONDITION

•

Clear DTC from memory using WDS or

equivalent.

•

Is repair shop possible to perform Drive Mode

4?

Yes Go to next step.

No

Go to step 31.

28

VERIFY MONITORING CONDITION FOR

EVAPORATIVE SYSTEM TEST OR DRIVE

MODE 4

•

Turn ignition key to ON (Engine OFF).

•

Verify that following conditions are met.

— Barometric pressure: 72.2 kPa {542 mmHg,

21.3 inHg} or higher

— Engine coolant temperature: –10.0—22.0

°°°°

C {14.0—72.0

°°°°

F} [at barometric pressure

72.2 kPa {542 mmHg, 21.3 inHg}]

— Intake air temperature: 10—60

°°°°

C {50—140

°°°°

F}

— Fuel tank level: 15—85%

•

Is there any conditions that is out of

specification?

Yes Take corrective action (e.g. cool down engine), then repeat

this step.

Note

•

Readings need to be in the indicated ranges to

perform Drive Mode.

No

Go to next step.

29

MONITOR EVAP SYSTEM BY DRIVE MODE 4

•

Run OBD-II Drive Mode 4.

(See 01–02A–13 Mode 4 (EVAP system repair

verification drive mode).)

•

Stop vehicle and access ON BOARD SYSTEM

READINESS TESTS to inspect Drive Mode

completion status.

•

Has EVAPORATIVE PURGE SYSTEM been

monitored?

Yes Go to next step.

No

Go back to Step 28.

STEP

INSPECTION

ACTION

1712-1U-01G(01-02A).fm 86 ページ 2001年6月29日 金曜日 午後2時20分