Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 962

7C–18

CLUTCH

Torque Specifications

D

Master cylinder to dash panel

Torque: 16 N·m (12 lb ft)

D

Clutch pedal to dash panel

Torque: 21 N·m (15 lb ft)

D

Master cylinder push rod to yoke

Torque: 17 N·m (12 lb ft)

D

Clutch pipe to master cylinder

Torque: 12 N·m (9 lb ft)

D

Clutch pipe to flexible hose

Torque: 16 N·m (12 lb ft)

D

Slave cylinder to case

Torque: 43 N·m (32 lb ft)

D

Slave cylinder bleeder screw

Torque: 8 N·m(69 lb in)

D

Flexible hose to slave cylinder

Torque: 20 N·m (14 lb ft)

Bleeding

1. Check the level of clutch fluid in the reservoir and

replenish if necessary

2. Bleeding the slave cylinder.

1. Remove the rubber cap from the bleeder screw

and wipe clean the bleeder screw. Connect a vinyl

tube to the bleeder screw and insert the other end

of the vinyl tube into a transparent container.

2. Pump the clutch pedal repeatedly and hold it

depressed.

203RS005

3. Loosen the bleeder screw to release clutch fluid

with air bubbles into the container, then tighten

the bleeder screw immediately.

4. Release the clutch pedal carefully. Repeat the

above operation until air bubbles disappear from

the clutch fluid being pumped out into the

container. During the bleeding operation, keep

the clutch fluid reservoir filled to the specified

level. Reinstall the rubber cap.

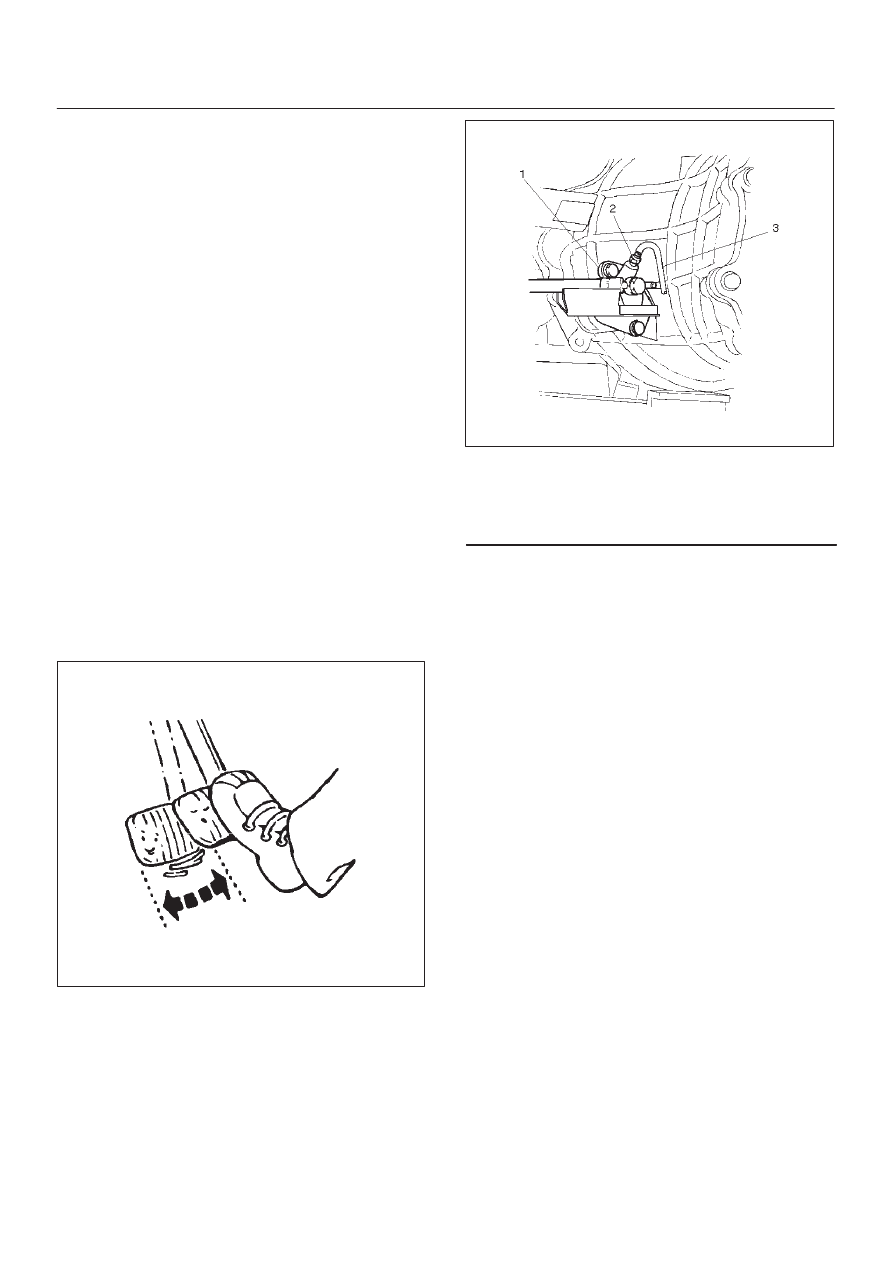

206RW003

Legend

(1) Slave Cylinder

(2) Bleeder Screw

(3) Vinyl Tube