Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 692

5C–12 POWER ASSISTED BRAKE SYSTEM

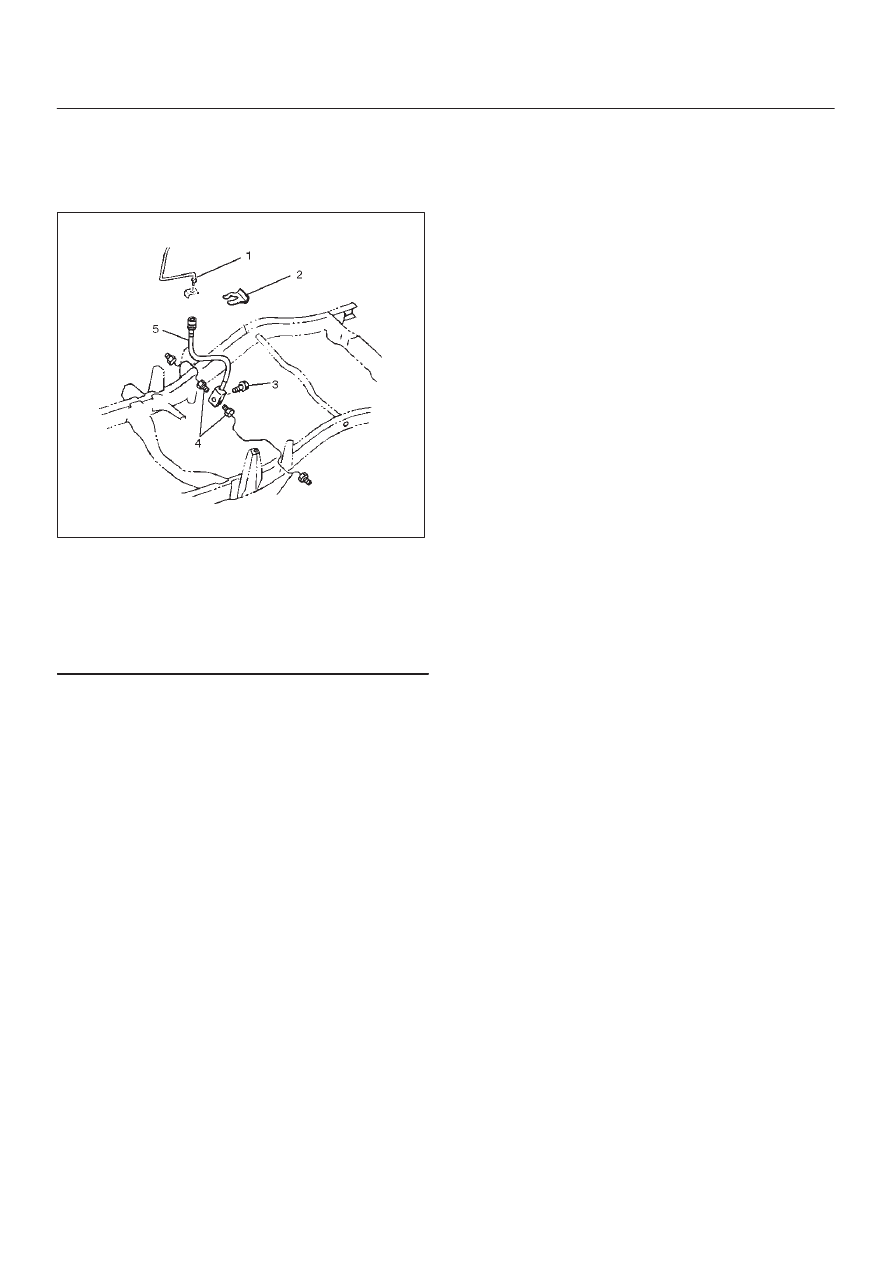

Rear Axle Brake Hose

Rear Axle Brake Hose and Associated

Parts

352RW002

Legend

(1) Brake Pipe

(2) Clip

(3) Bolt

(4) Brake Pipe

(5) Hose

Removal

1. Raise the vehicle and support it with suitable safety

stands.

2. Remove wheel and tire assembly.

3. Clean dirt, grease, and other foreign material off the

hose fittings at both ends.

4. Disconnect brake pipe.

5. Remove clip.

6. Remove brake pipe.

7. Remove bolt.

8. Remove hose.

Installation

To install, follow the removal steps in the reverse order,

noting the following points:

1. Tighten the brake pipes to the specified torque

Torque: 16 N·m (12 lb ft)

2. Tighten the bolt to the specified torque.

Sems bolts

Torque: 13 N·m (113 lb in)

Flange bolts

Torque: 15 N·m (11 lb ft)

After installing the brake hoses, bleed the brakes as

described in this section.