Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 549

1A–64 HEATING, VENTILATION AND AIR CONDITIONING (HVAC)

4. O-rings cannot be reused. Always replace with new

ones.

5. Be sure to apply new compressor oil to the O-rings

when connecting lines.

6. Be sure to install the sensor and the insulator on the

place where they were before.

7. To install a new evaporator core, add 50cm

3

(1.7 fl.

oz.) of new compressor oil to the new core.

8. Tighten the refrigerant lines to the specified torque.

Refer to Main Data and Specifications for Torque

Specifications in this section.

9. Apply an adhesive to the parting face of the lining

when assembling the evaporator assembly.

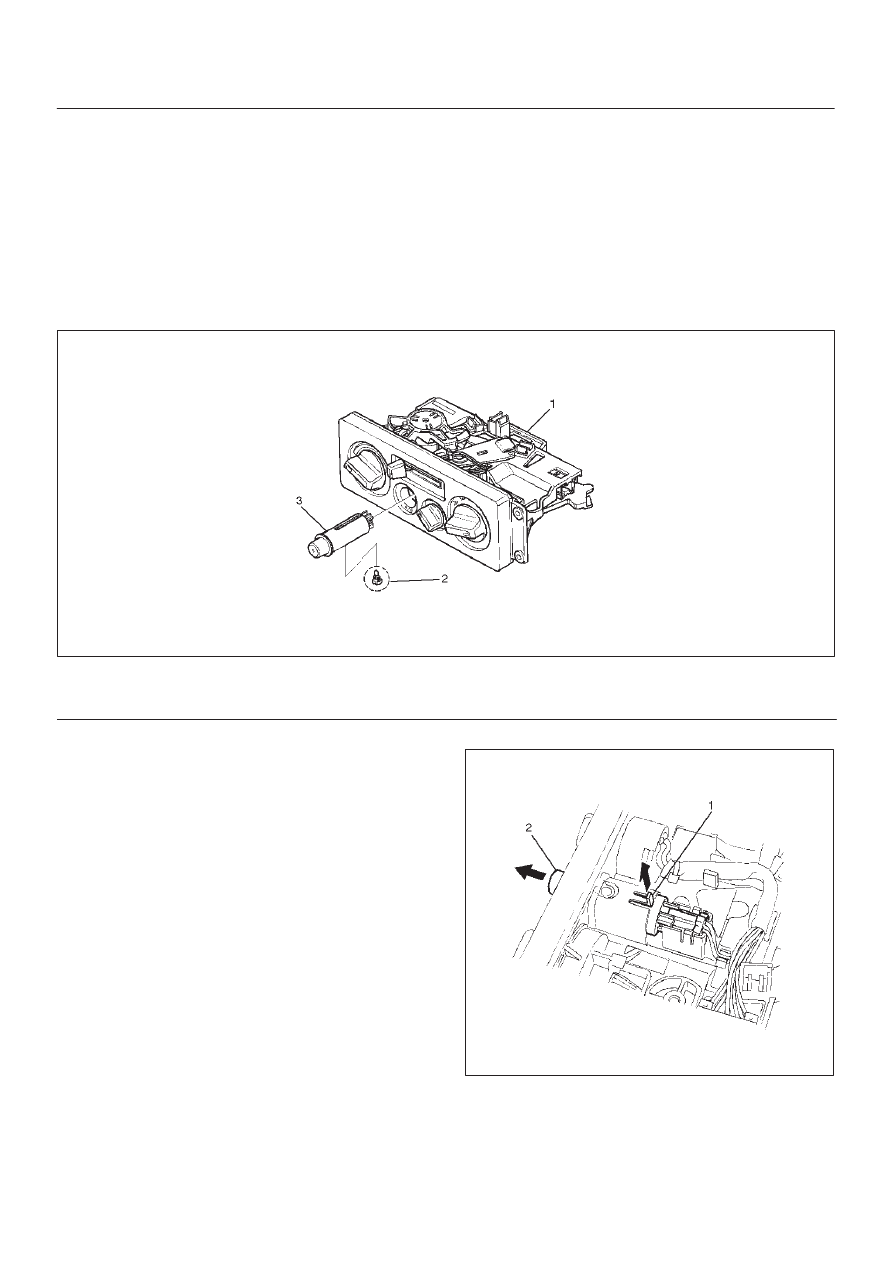

Air Conditioning Switch and Illumination Bulb

Air Conditioning Switch, Illumination Bulb and Associated Parts

865RS003

Legend

(1) Control Lever Assembly

(2) Illumination Bulb

(3) A/C Switch

Removal

1. Disconnect the battery ground cable.

2. Remove control lever assembly.

D

Refer to Control Lever Assembly in this section.

3. Lift up the catch portion (1) of the switch and remove

the air conditioning switch (2) while pushing it toward

the outside.

865RS004

4. Turn the illumination bulb counterclockwise to

remove.

Installation

To install, follow the removal steps in the reverse order.