Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 541

1A–32 HEATING, VENTILATION AND AIR CONDITIONING (HVAC)

The refrigeration cycle includes the following four

processes as the refrigerant changes repeatedly from

liquid to gas and back to liquid while circulating.

Evaporation

The refrigerant is changed from a liquid to a gas inside the

evaporator. The refrigerant mist that enters the

evaporator vaporizes readily. The liquid refrigerant

removes the required quantity of heat (latent heat of

vaporization) from the air around the evaporator core

cooling fins and rapidly vaporizes. Removing the heat

cools the air, which is then radiated from the fins and

lowers the temperature of the air inside the vehicle.

The refrigerant liquid sent from the expansion valve and

the vaporized refrigerant gas are both present inside the

evaporator as the liquid is converted to gas.

With this change from liquid to gas, the pressure inside

the evaporator must be kept low enough for vaporization

to occur at a lower temperature. Because of that, the

vaporized refrigerant is sucked into the compressor.

Compression

The refrigerant is compressed by the compressor until it is

easily liquefied at normal temperature.

The vaporized refrigerant in the evaporator is sucked into

the compressor. This action maintains the refrigerant

inside the evaporator at a low pressure so that it can

easily vaporize, even at low temperatures close to

0

°

C(32

°

F).

Also, the refrigerant sucked into the compressor is

compressed inside the cylinder to increase the pressure

and temperature to values such that the refrigerant can

easily liquefy at normal ambient temperatures.

Condensation

The refrigerant inside the condenser is cooled by the

outside air and changes from gas to liquid.

The high temperature, high pressure gas coming from the

compressor is cooled and liquefied by the condenser with

outside air and accumulated in the receiver/drier. The

heat radiated to the outside air by the high temperature,

high pressure gas in the compressor is called heat of

condensation. This is the total quantity of heat (heat of

vaporization) the refrigerant removes from the vehicle

interior via the evaporator and the work (calculated as the

quantity of heat) performed for compression.

Expansion

The expansion valve lowers the pressure of the

refrigerant liquid so that it can easily vaporize.

The process of lowering the pressure to encourage

vaporization before the liquefied refrigerant is sent to the

evaporator is called expansion. In addition, the expansion

valve controls the flow rate of the refrigerant liquid while

decreasing the pressure.

That is, the quantity of refrigerant liquid vaporized inside

the evaporator is determined by the quantity of heat which

must be removed at a prescribed vaporization

temperature. It is important that the quantity of refrigerant

be controlled to exactly the right value.

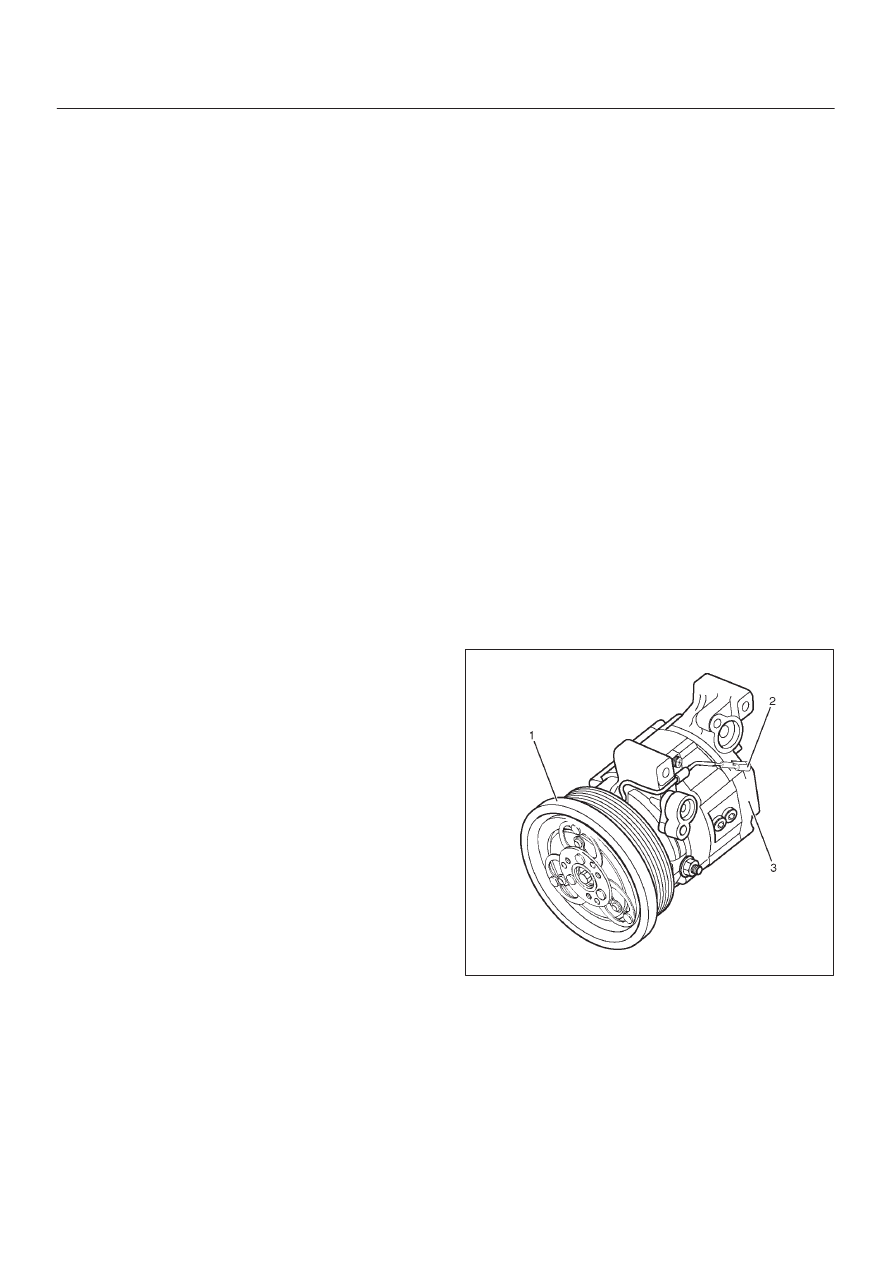

Compressor

The compressor performs two main functions:

It compresses low-pressure and low-temperature

refrigerant vapor from the evaporator into high-pressure

and high-temperature refrigerant vapor to the condenser.

It pumps refrigerant and refrigerant oil through the air

conditioning system.

This vehicle is equipped with six-cylinder axle plate

compressor (3).

The specified amount of the compressor oil is 240cm

3

(8.0 fl. oz.).

The oil used in the HFC-134a system compressor differs

from that used in R-12 systems.

Also, compressor oil to be used varies according to the

compressor model. Be sure to avoid mixing two or more

different types of oil.

If the wrong oil is used, lubrication will be poor and the

compressor will seize or malfunction.

The magnetic clutch connector is a waterproof type.

Magnetic Clutch

The compressor is driven by the drive belt from the crank

pulley of the engine. If the compressor is activated each

time the engine is started, this causes too much load to

the engine. The magnetic clutch (1) transmits the power

from the engine to the compressor and activates it when

the air conditioning is ON. Also, it cuts off the power from

the engine to the compressor when the air conditioning is

OFF. Refer to Compressor in this section for magnetic

clutch repair procedure.

871R200002

Condenser

Also, it functions to cool and liquefy the high-pressure and

high-temperature vapor sent from the compressor by the

radiator fan or outside air.

A condenser may malfunction in two ways: it may leak, or

it may be restricted. A condenser restriction will result in

excessive compressor discharge pressure. If a partial

restriction is present, the refrigerant expands after

passing through the restriction.

Thus, ice or frost may form immediately after the

restriction. If air flow through the condenser or radiator is