Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 531

0B–4

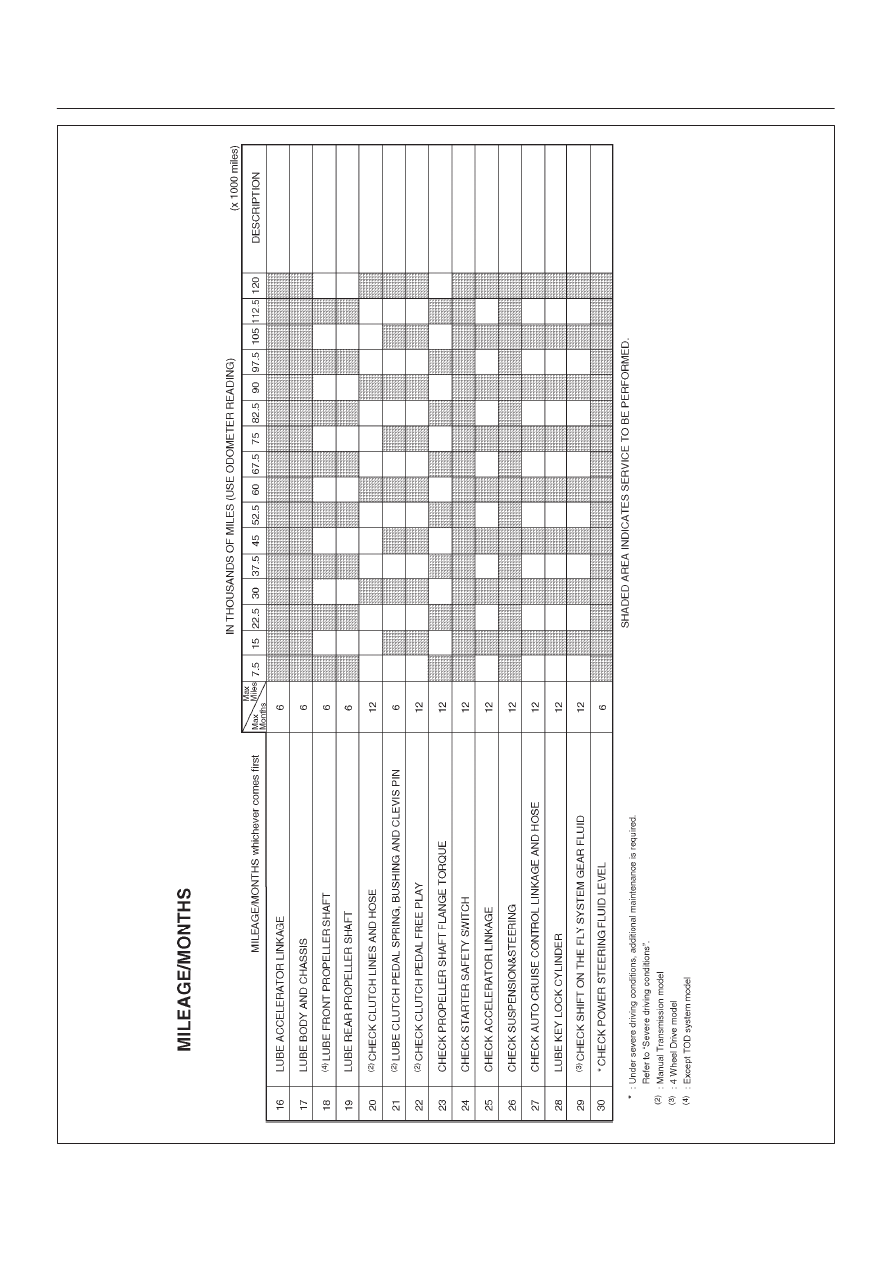

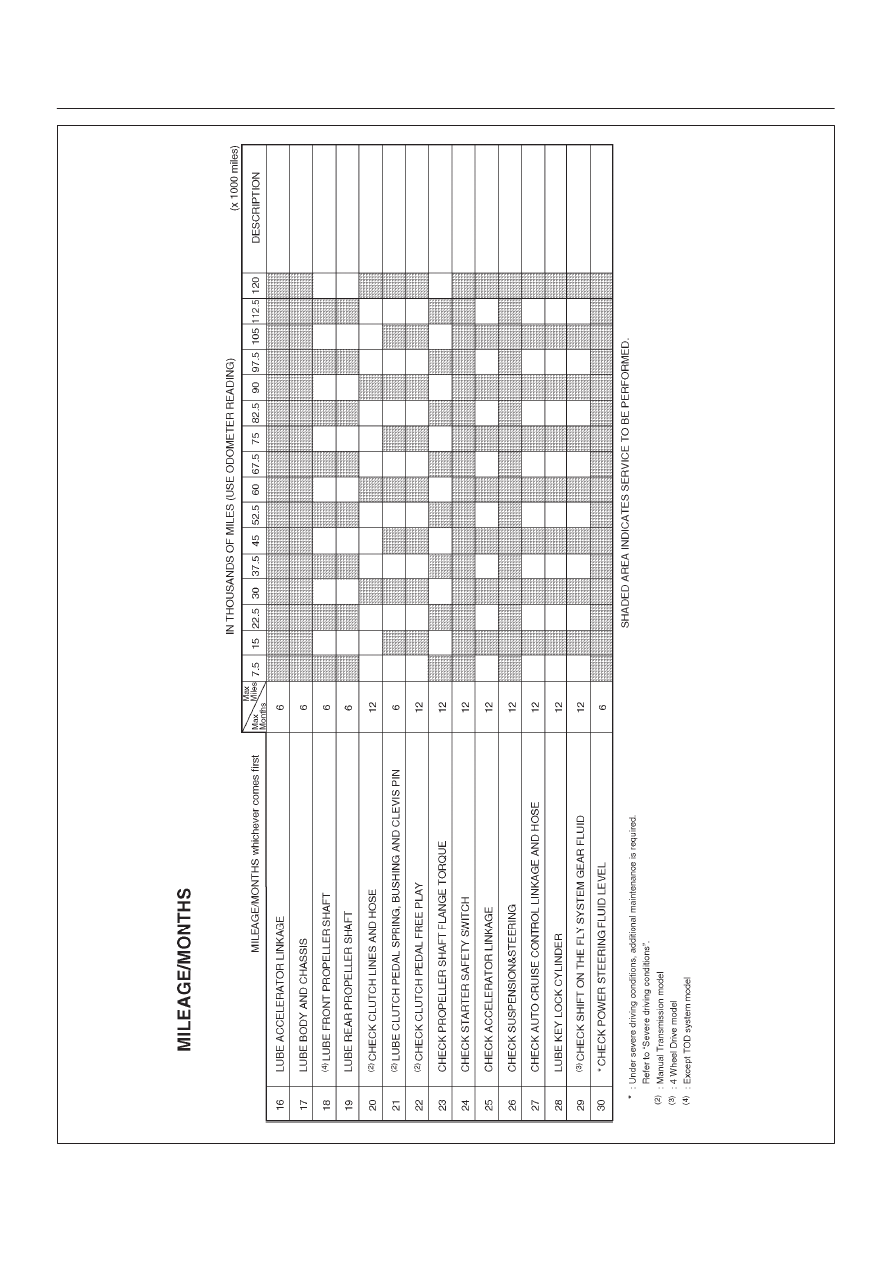

MAINTENANCE AND LUBRICATION

02UBSOM4–1

Index Isuzu Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross - service repair manual 1999-2002 year

|

|

|

0B–4 MAINTENANCE AND LUBRICATION 02UBSOM4–1 |