Content .. 1606 1607 1608 1609 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1608

7C–8

CLUTCH

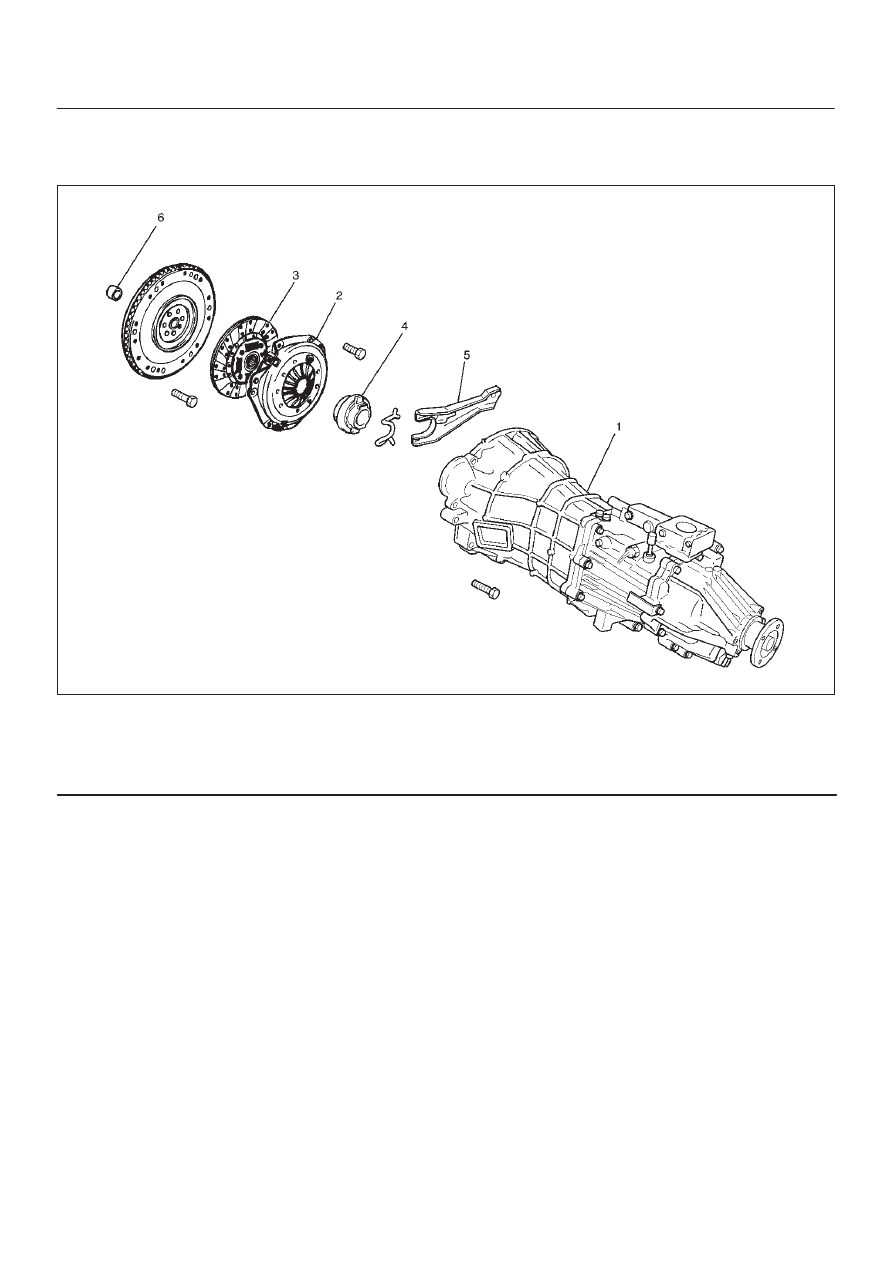

Clutch Assembly (Y22SE)

Clutch Assembly (Y22SE) and Associated Parts

201RX003

Legend

(1) Transmission Assembly

(2) Pressure Plate Assembly

(3) Driven Plate Assembly

(4) Release Bearing

(5) Shift Fork

(6) Crank Shaft Bearing

Removal

1. Remove transmission assembly, refer to “MANUAL

TRANSMISSION” of Section 7B for “REMOVAL AND

INSTALLATION” procedure.