Content .. 1556 1557 1558 1559 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1558

7A–72

AUTOMATIC TRANSMISSION (4L30–E)

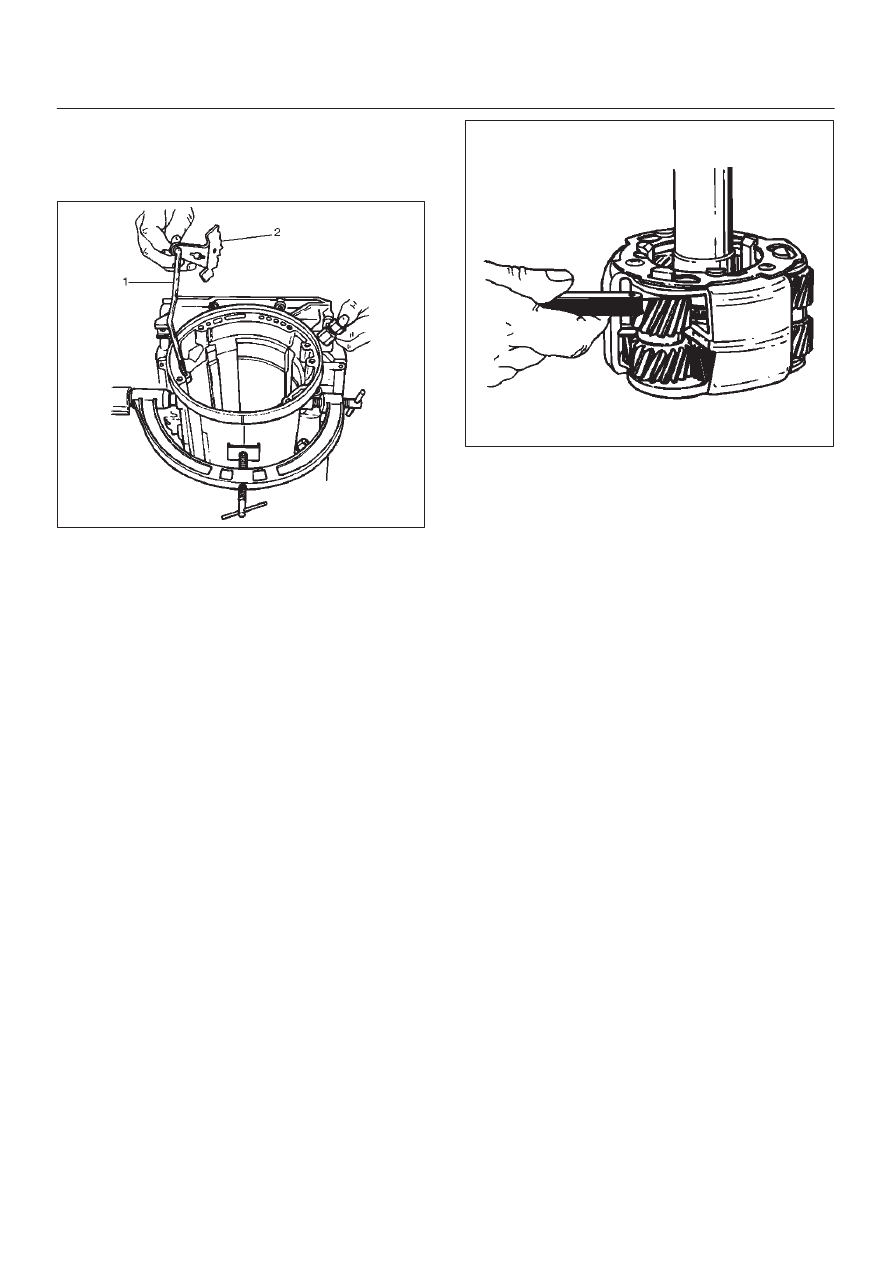

4. Install parking lock and range selector lever (2) and

new 17 mm nut. Tighten the nut to the specified

torque.

Torque: 22 N

•

m (16 lb ft)

249RS005

5. Rotate main case to vertical position, extension end

facing down.

D

Install brake band assembly (3).

NOTE: Be sure to align servo pin area with the servo hole.

6. Install thrust bearing (4).

NOTE: The case bushing acts as a guide for the thrust

bearing.

7. Install brake drum (5).

8. Install reaction sun gear (6).

9. Install needle bearing (7).

10. Inspect planetary carrier assembly (8) for wear and

damage. If necessary replace it.

D

Measure pinion end play clearance with a feeler

gauge.

Clearance: 0.13mm–0.89mm (0.005 in–0.035 in)

If clearance is outside specified value, replace the

planetary carrier assembly.

248RS001

11. Install the thrust bearing (9) on the output shaft.

NOTE: Use petroleum jelly to hold the thrust bearing in

place.

12. Align planetary pinions. Each pinion is marked with

double points to indicate the master tooth space and

exactly opposite with a single point to indicate the

master tooth. The markings on the planetary carrier

consist of double lines which are to be lined up with

the double points on two opposite pinions; the single

lines are to be lined up with the single points on the

other two pinions.

D

After all four pinions are lined up, slide on the third

clutch assembly. Rotate third clutch and check

mark alignment. Considering that the ring gear

tooth between the double points of one planetary

pinion is tooth number 1, count the teeth to check

that the single points on the two adjacent pinions

are between teeth 23 and 24 of the ring gear, and

that the ring gear tooth between the double points of

the opposite pinion is tooth number 46. If the ring

gear and pinions are not lined up, remove and

realign them.