Content .. 1555 1556 1557 1558 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1557

7A–68

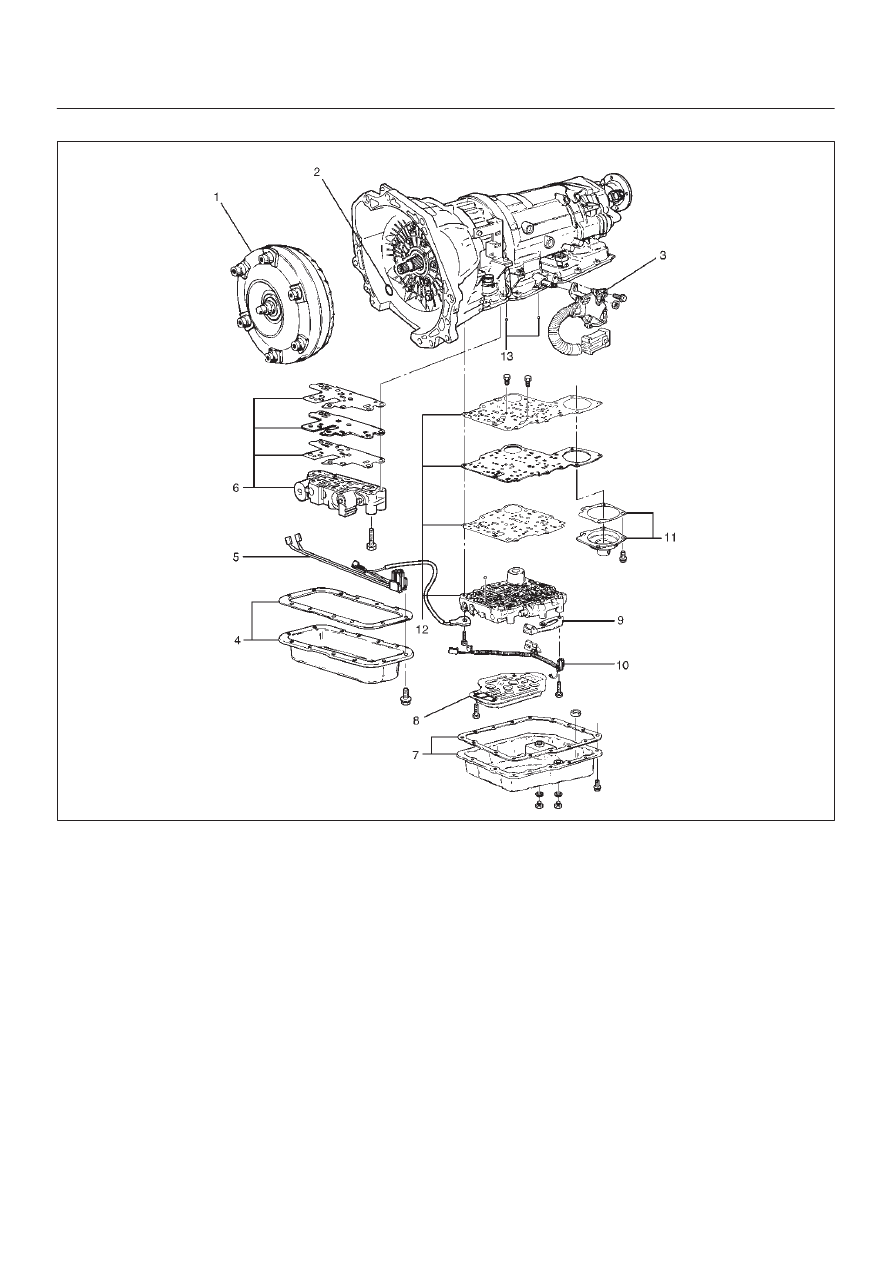

AUTOMATIC TRANSMISSION (4L30–E)

(HEC)

240R100008

14. Turn transmission to vertical position to drain fluid.

Return back to horizontal position when drained.

D

Install J–23075 servo piston spring compressor

with offset to the rear of case.

D

Compress servo piston assembly.

D

Remove servo piston retaining ring (14).

D

Slowly release servo piston assembly (15).

D

Remove tool.