Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 144

4C–76

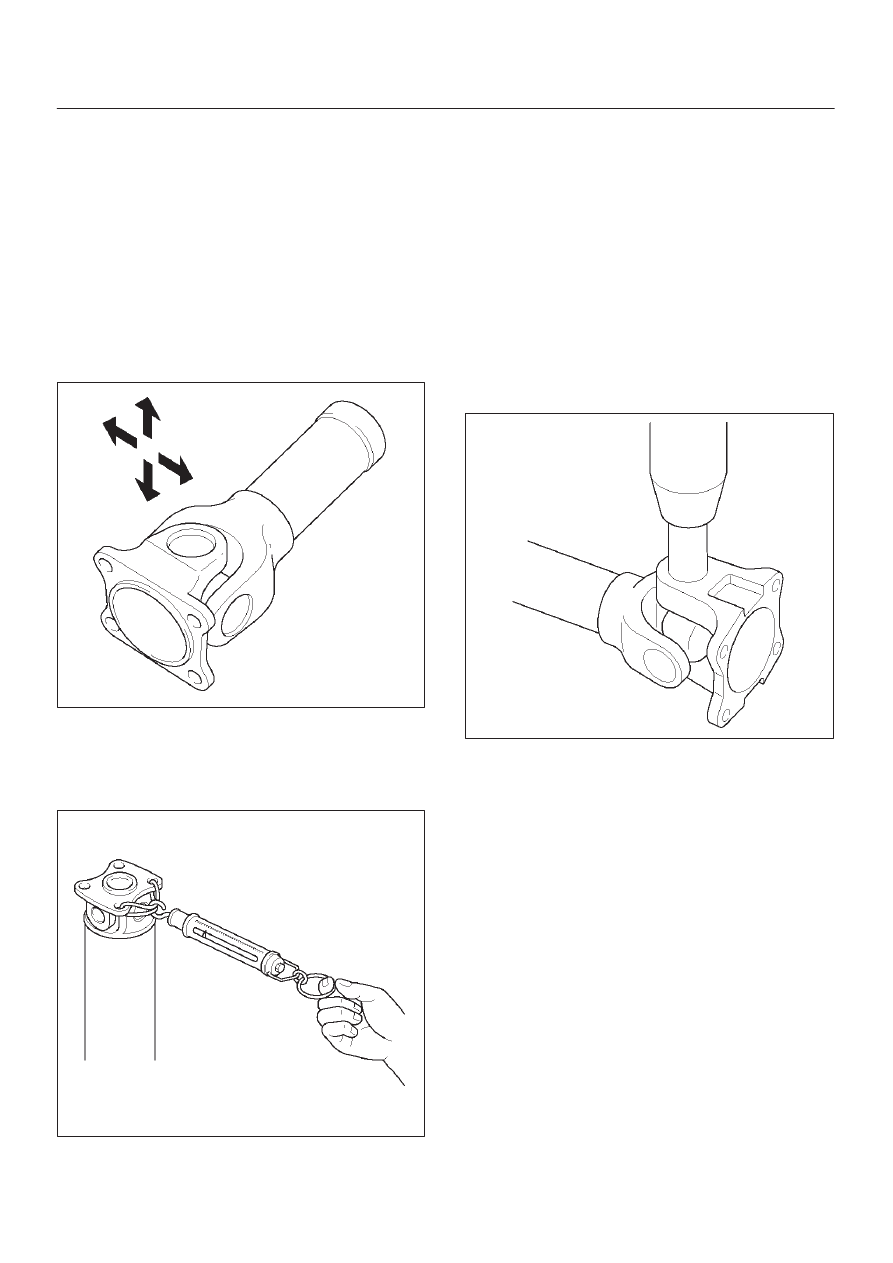

DRIVE SHAFT SYSTEM

Spline

The nylon-coated spline should be free from nicks and

dings and the underlying steel spline should not be visible.

After cleaning the nylon coating spline, the coating should

exhibit only slight indicator of wear.

Grease volume is approximately 10 grams of grease in

total. Grease should be evenly applied to both the female

and the male slip splines using a small brush. After

assembly of the slip joint, the sliding joint should be fully

worked from the full collapsed to the full extended

position.

Play in the universal joint

Limit: Less than 0.15 mm (0.006 in)

401RW023

Preload of the universal joint

Preload should be 0 to 49 N(0 to11.0 lb). Joints should

rotate smoothly and freely and should exhibit no rough or

ratchety movement.

401RW019

Universal Joint Reassembly

1. Install spider to flange yoke. Be sure to install the

spider by aligning the setting marks made during

disassembly.

2. Pack the four grease cavities of the spider with a high

quality, extreme pressure N.L.G.I. Grade 2 grease.

Do not add additional grease to the bearing cup

assembly.

3. Move one end of the spider to cause a trunnion to

project through the spider hole beyond the outer

machined face of the yoke lug. Place a bearing over

the trunnion diameter and align it to the spider hole.

Using an arbor press, hold the trunnion in alignment

with the spider hole and place a solid plug on the

upper bearing. Press the bearing into the spider hole

enough to install a snap ring.

401RW020

4. Install a snap ring.

Be sure the snap rings are properly seated in the

grooves.

5. Repeat steps 3 and 4 to install the opposite bearing. If

the joint is stiff, strike the yoke ears with a soft

hammer to seat needle bearings.