Content .. 1298 1299 1300 1301 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1300

6E1–276

RODEO Y22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

DIAGNOSTIC TROUBLE CODE (DTC) P0446 EVAPORATIVE EMISSION (EVAP)

CONTROL SYSTEM VENT CONTROL CIRCUIT MALFUNCTION

060R100040

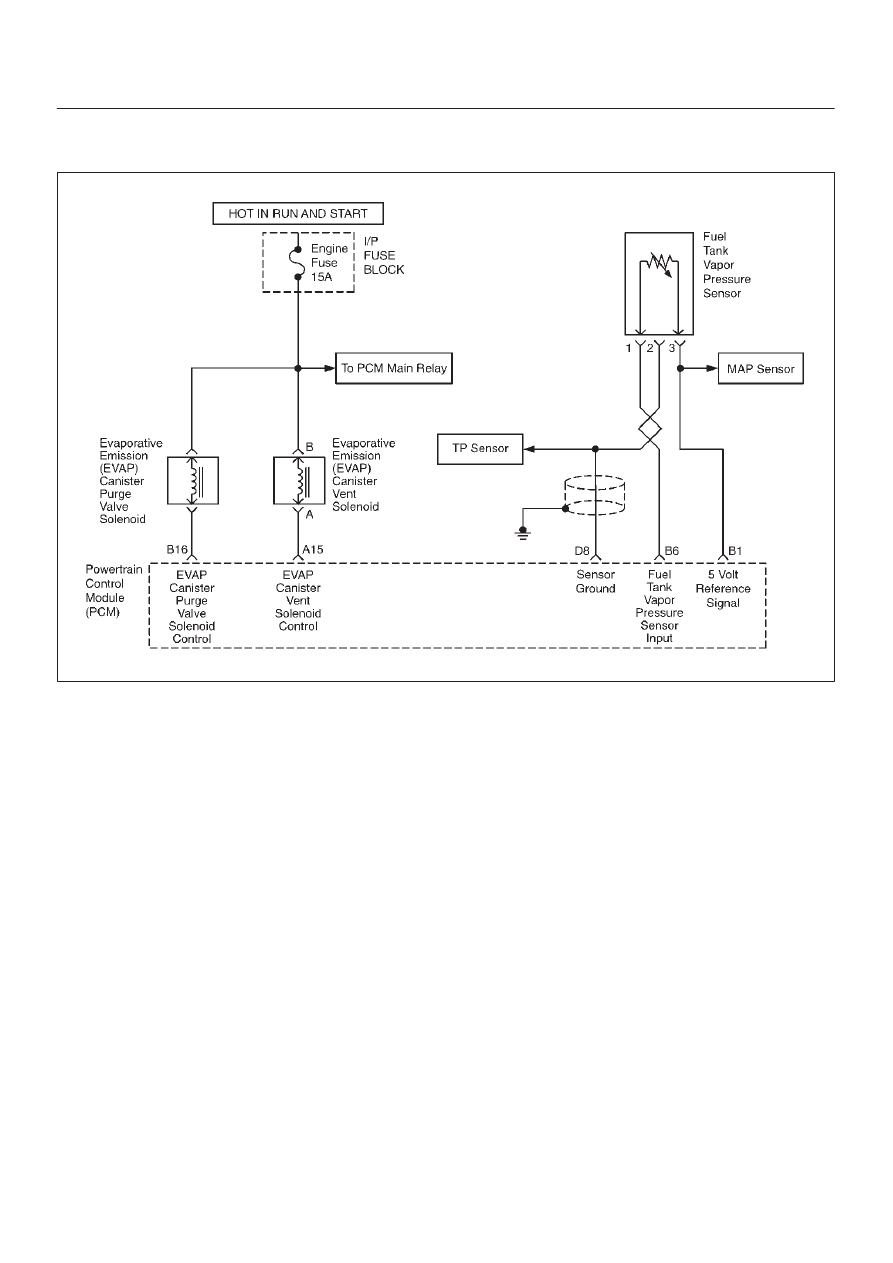

Circuit Description

The evaporative system includes the following

components:

D

Fuel tank.

D

EVAP vent solenoid.

D

Fuel tank pressure sensor.

D

Fuel pipes and hoses.

D

Fuel vapor lines.

D

Fuel cap.

D

EVAP canister.

D

Purge lines.

D

EVAP canister purge valve.

D

EVAP service port.

The evaporative emission system is checked by applying

vacuum to the EVAP system and monitoring for a vacuum

decay. The PCM monitors the vacuum level through the

fuel tank pressure sensor signal.

At an appropriate time, the EVAP canister purge valve

and the EVAP vent solenoid are turned ON, allowing the

engine to draw a small vacuum on the entire evaporative

emission system. After the desired vacuum level has

been achieved, the EVAP canister purge valve is turned

OFF, sealing the system.

A restricted or blocked EVAP canister vent path is

detected by drawing a vacuum on the EVAP system,

turning OFF the EVAP vent solenoid and the EVAP

canister purge valve (EVAP vent solenoid Open, EVAP

purge PWM 0%) and monitoring the fuel tank vacuum

sensor input. With the EVAP vent solenoid open, any

vacuum in the system should decrease quickly unless the

vent path is blocked. A blockage can be caused by the

following conditions:

D

Faulty EVAP vent solenoid (stuck closed).

D

Plugged, kinked or pinched vent hose.

D

Shorted EVAP vent solenoid driver circuit.

D

Plugged evaporative canister.

If any of these conditions are present, Diagnostic Trouble

Code P0446 will set. DTC P0446 is a type B code.

Conditions for Setting the DTC

D

The BARO is greater than 72.3 kPa.

D

No: MAP, TPS, IAT, ECT, EGR, EVAP Purge Solenoid,

EVAP Vent Solenoid, VSS or System Voltage

Diagnostic Trouble Codes.

D

IAT and ECT at startup are between 4.2

°

C(40

°

F) and

35

°

C (95

°

F).

D

The difference between IAT and ECT at startup is less

than 6.75

°

C (12.2

°

F).

D

The Fuel Tank Level Sensor reads between 15% and

85%.

The above conditions are met, and the following condition

is met once while ignition cycle: