Content .. 1243 1244 1245 1246 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1245

6E1–56

RODEO Y22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

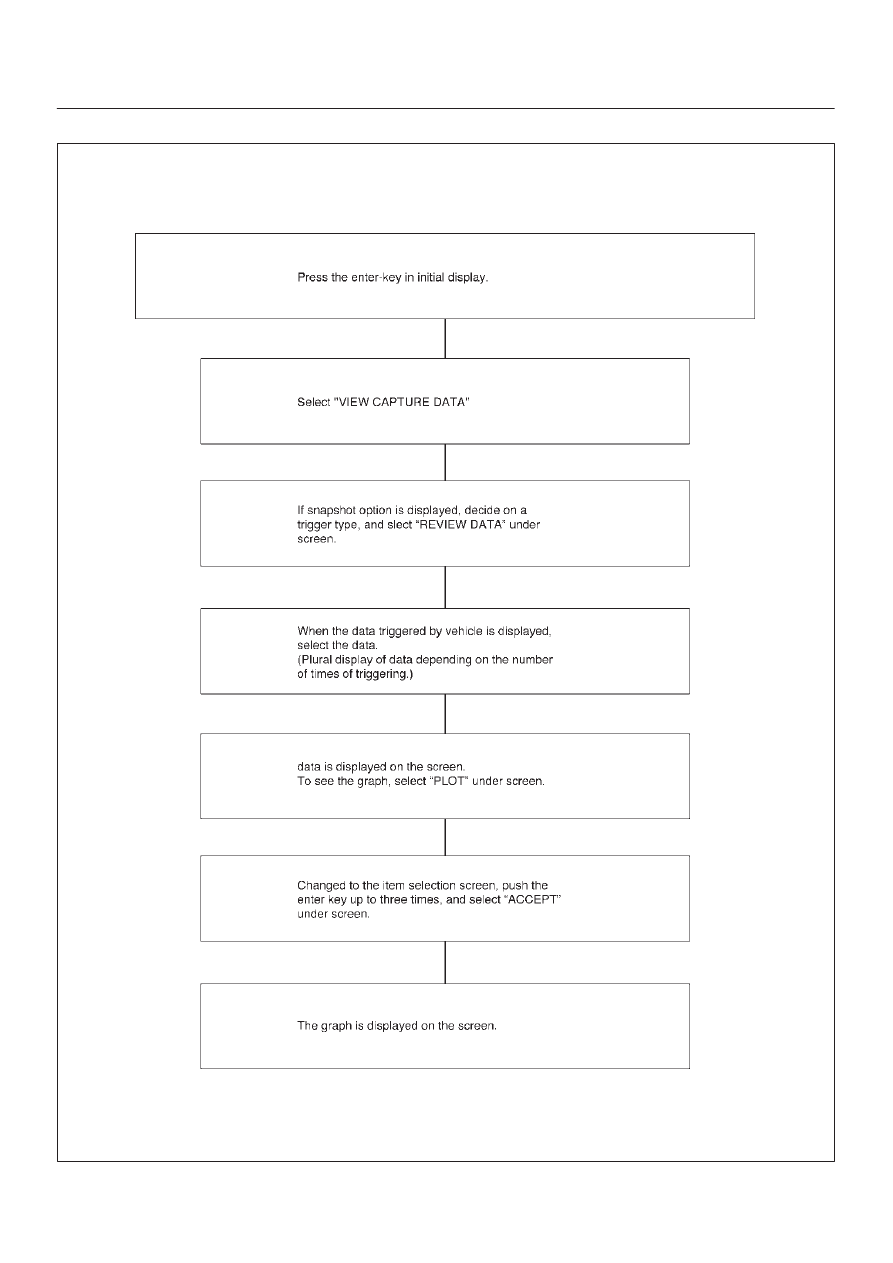

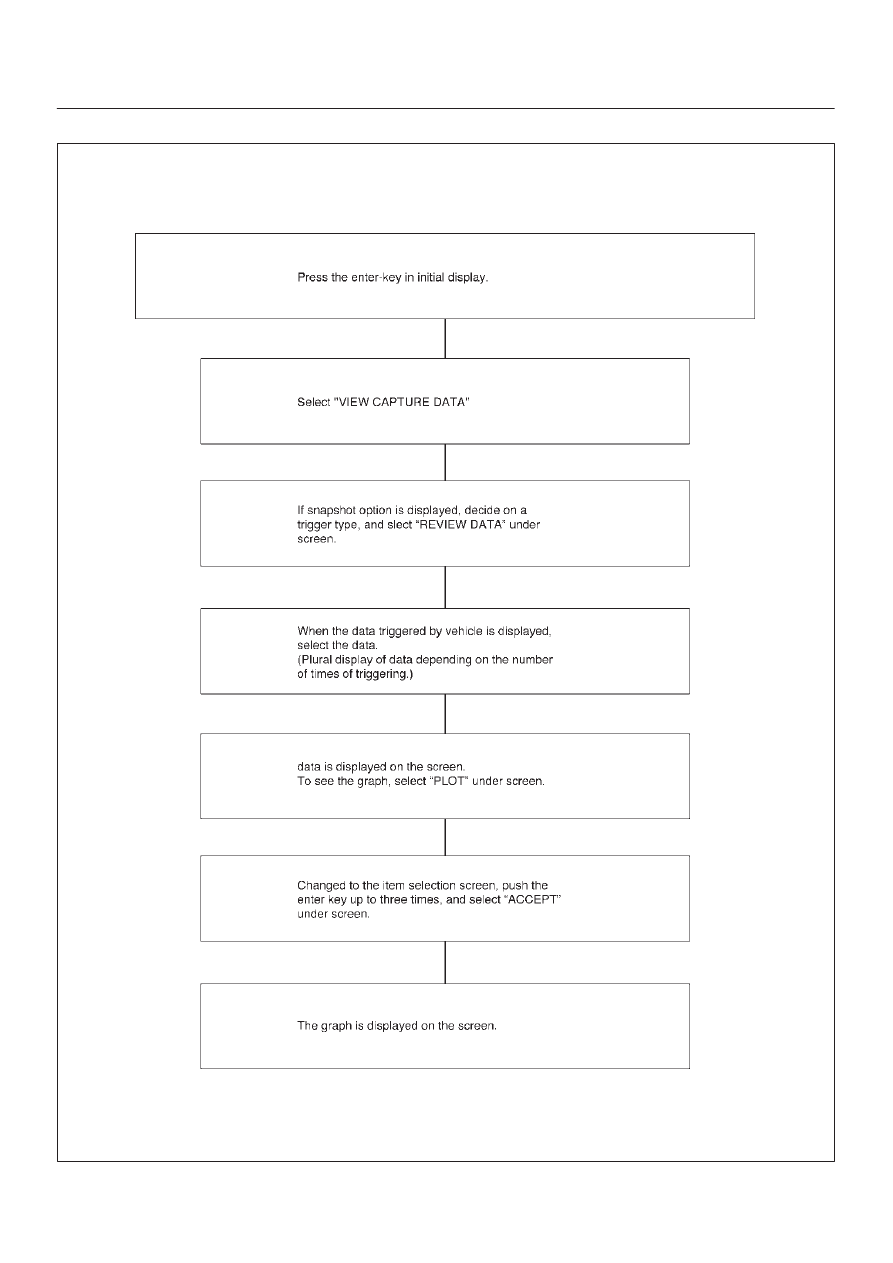

Flow Chart for Snapshot Replay (Plotting Graph)

060RX040

Index Isuzu Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross - service repair manual 1999-2002 year

|

|

|

Content .. 1243 1244 1245 1246 ..

6E1–56 RODEO Y22SE 2.2L ENGINE DRIVEABILITY AND EMISSION Flow Chart for Snapshot Replay (Plotting Graph) 060RX040 |