Content .. 1192 1193 1194 1195 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1194

POWER-ASSISTED BRAKE SYSTEM

5C–43

306RW005

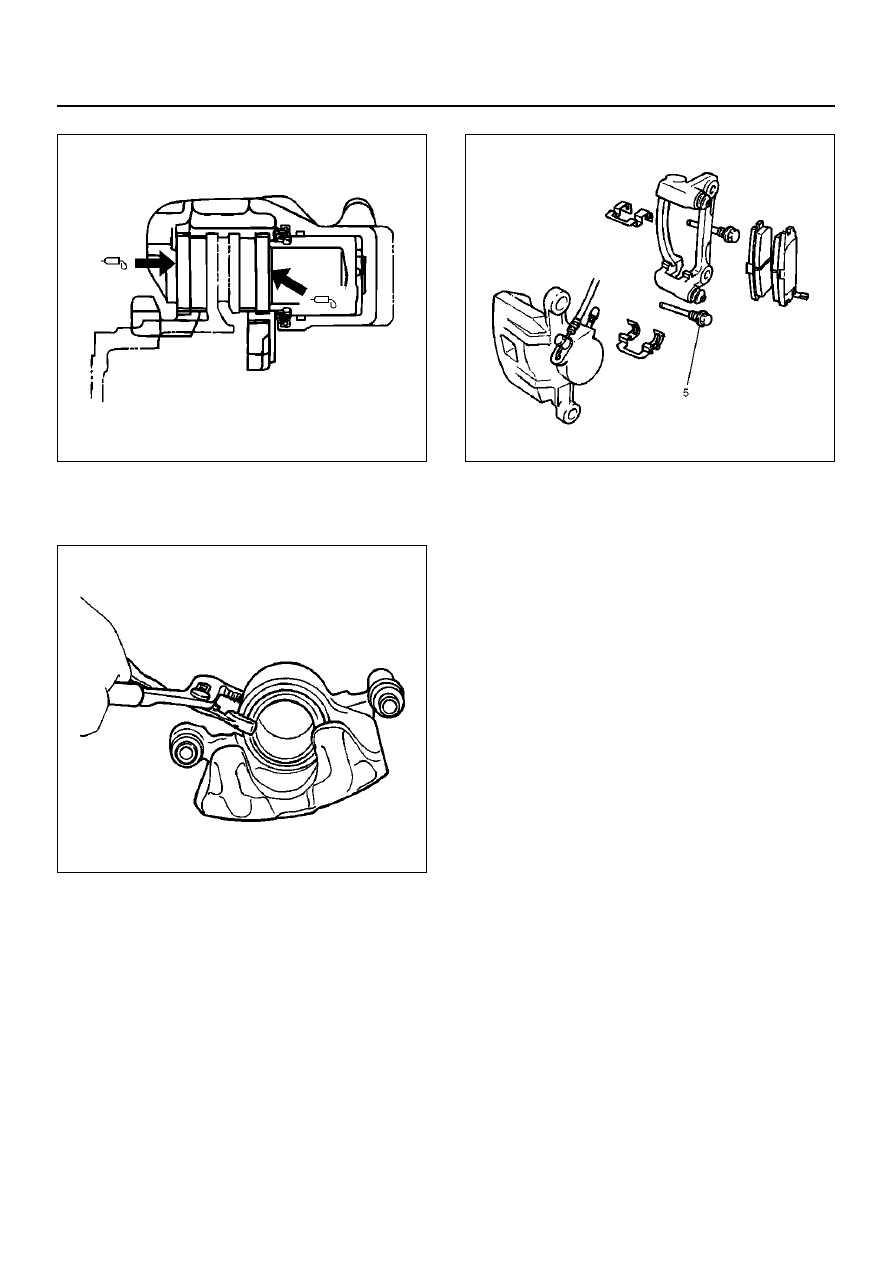

3. Carefyully use adjustable pliers to bottom the piston

into the caliper bore. Do not pull or twist the flex

hose or damage will occur.

302RS008

4. Install lock bolt (5) and tighten the bolt to the

specified torque.

Torque: 44 N·m (32 lb ft)

5. Install wheel and tire assembly, referring to Wheels

and Tires System in Section 3E.

6. Pump the brake pedal several times to make sure

that the pedal is firm. Check the brake fluid level in

the reservoir after pumping the brakes.

306RW006