Content .. 1153 1154 1155 1156 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1155

4C–32

DRIVE SHAFT SYSTEM

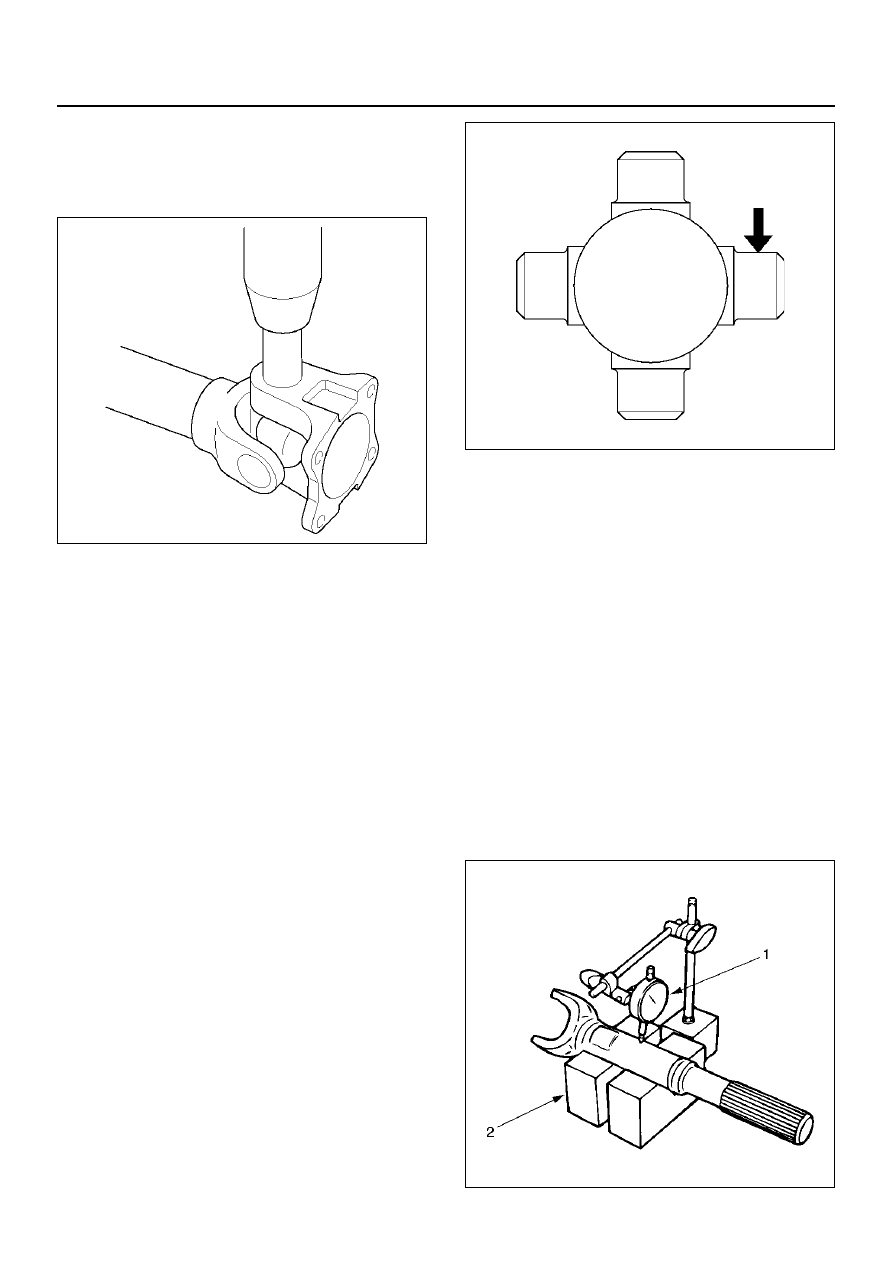

2. Set the yoke in the arbor press with a piece of tube

stock beneath it.

Place a solid plug on the upper bearing assembly

and press it through to release the lower bearing

assembly.

401RW020

3. If the bearing assembly will not pull out by hand

after pressing, tap the base of the lug near the

bearing assembly to dislodge it.

4. To remove the opposite bearing, turn the yoke over

and straighten the spider in the open hole. Then

carefully press on the end of the spider so the

remaining bearing moves straight out of the bearing

spider hole. If the spider or bearing are cocked, the

bearing will score the walls of the spider hole and

ruin the yoke.

5. Repeat this procedure on the remaining bearing to

remove the spider from the yoke.

6. Make sure of proper position for reinstallation by

applying setting marks, then remove spider .

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition is

found through inspection.

NOTE: When any part of the journal assembly (spider,

needle roller bearing) requires replacement, be sure to

replace the entire assembly.

Check the following parts for wear, damage, noise or

any other abnormal conditions.

1. Spider

2. Needle roller bearing

3. Yoke

4. Flange

5. Boot

Spider pin for wear

Spider pin should be smooth and free from fretting or

galling. Visible signs of needle presence is normal, but

wear should not be felt.

401RW038

Propeller shaft run–out

Support the propeller shaft on V-blocks (2) and check

for run-out by holding the probe of a dial indicator (1) in

contact with the shaft.

Static run-out limit:

0.13 mm (0.005in)

TIR on the neck of the slip tube shaft (with a

boot).

0.25 mm (0.010in)

TIR on the ends of the tubing 3 inch from the

welds.

0.38 mm (0.015in)

TIR at the linear center of the tube.

0.38 mm (0.015in)

TIR for the full length of tube with 30" or less of

tubing.

(TIR : Total Indicator Reading)

401RS027