Content .. 1134 1135 1136 1137 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1136

4A2–12

DIFFERENTIAL (REAR)

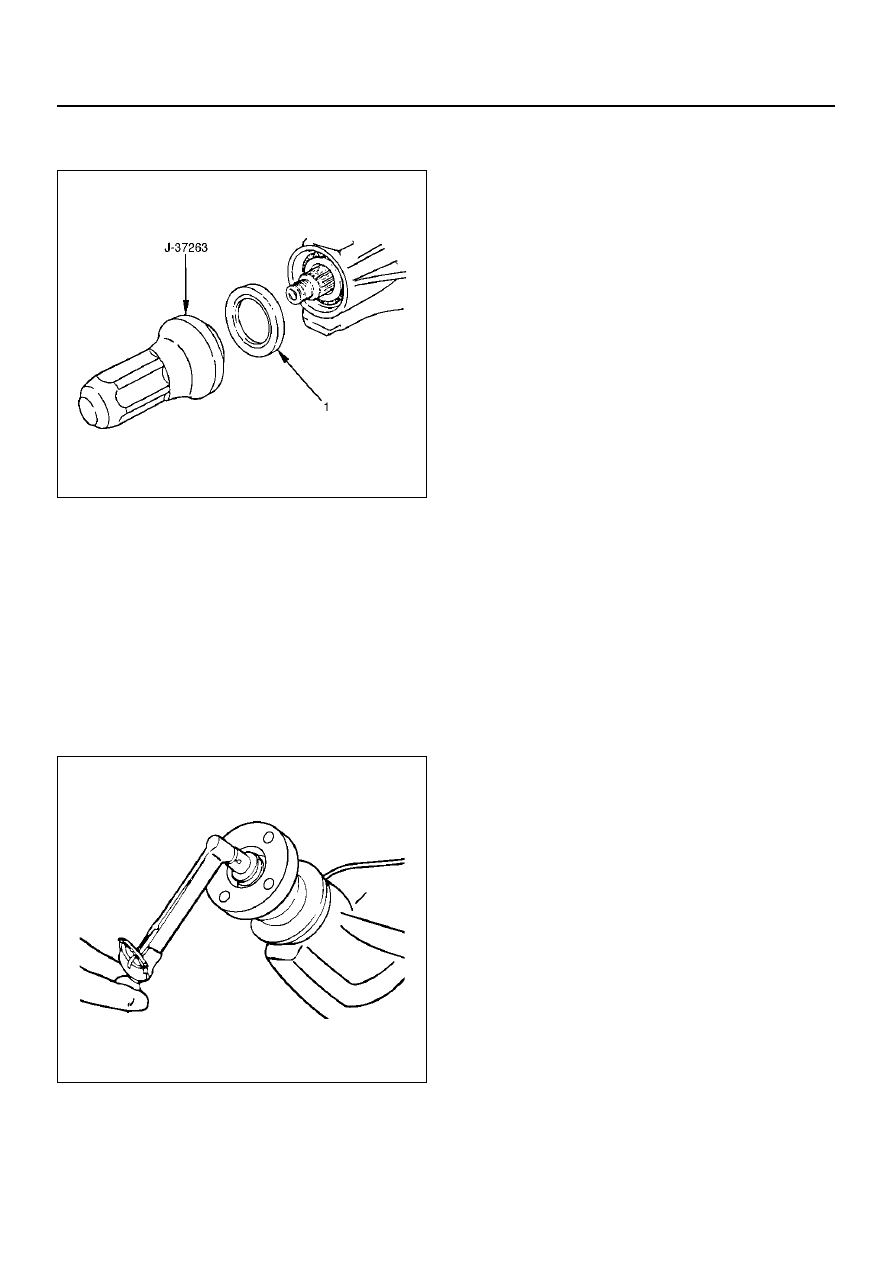

3. By using the seal installer J–37263, install a new oil

seal (1) that has grease on seal lip.

425RS004

4. Install flange.

5. The pinion washer and a new nut while holding the

pinion flange with J–8614–01.

• Tighten the nut until the pinion end play is just

taken up. Rotate the pinion while tightening the

nut to seat the bearings. Once there is not end

play in the pinion, the preload torque should be

checked.

• Remove J–8614–01. Using an inch-pound torque

wrench, check to make sure the pinion preload is

equal to or slightly over the reading recorded

during removal.

425RW018

6. Install propeller shaft to the frange.

7. Install bolt and nut. Tighten the bolt and nut to the

specified torque.

Torque: 63 N·m (46 lb ft)