Content .. 1104 1105 1106 1107 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1106

FRONT SUSPENSION

3C–11

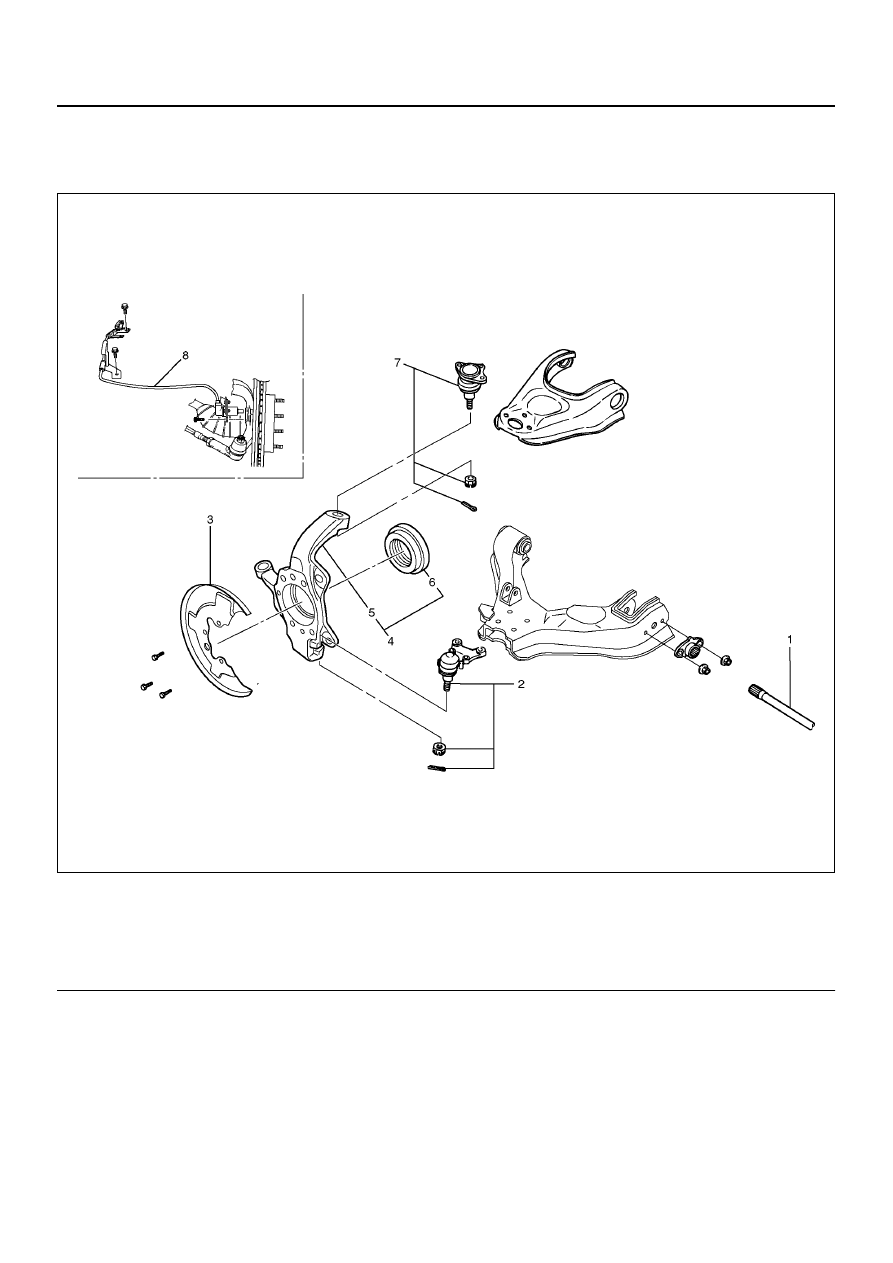

Knuckle

Knuckle and Associated Parts

410R200002

EndOFCallout

Removal

1. Raise the vehicle and support the frame with

suitable safety stands.

2. Remove wheel and tire assembly. Refer to Wheel in

this section.

3. Remove the brake caliper. Refer to Disc Brakes in

Brake section.

4. Remove the disk rotor. Refer to Disk Brakes in

Brake section.

5. Remove the hub assembly. Refer to Front Hub and

Disk in this section.

6. Remove tie–rod end from the knuckle. Refer to

Power Steering Unit in Steering section.

7. Remove the speed sensor from the knuckle.

8. Loosen torsion bar by height control arm adjust bolt,

then remove torsion bar. Refer to Torsion Bar in this

section.

9. Remove wheel speed sensor. (4x4 model)

Legend

(1) Torsion Bar

(2) Lower Ball Joint, Nut and Cotter Pin

(3) Back Plate

(4) Knuckle Assembly

(5) Knuckle

(6) Oil Seal

(7) Upper Ball Joint, Nut and Cotter Pin

(8) Wheel Speed Sensor (4x4 model)