Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 92

4A2–26

DIFFERNTIAL (REAR)

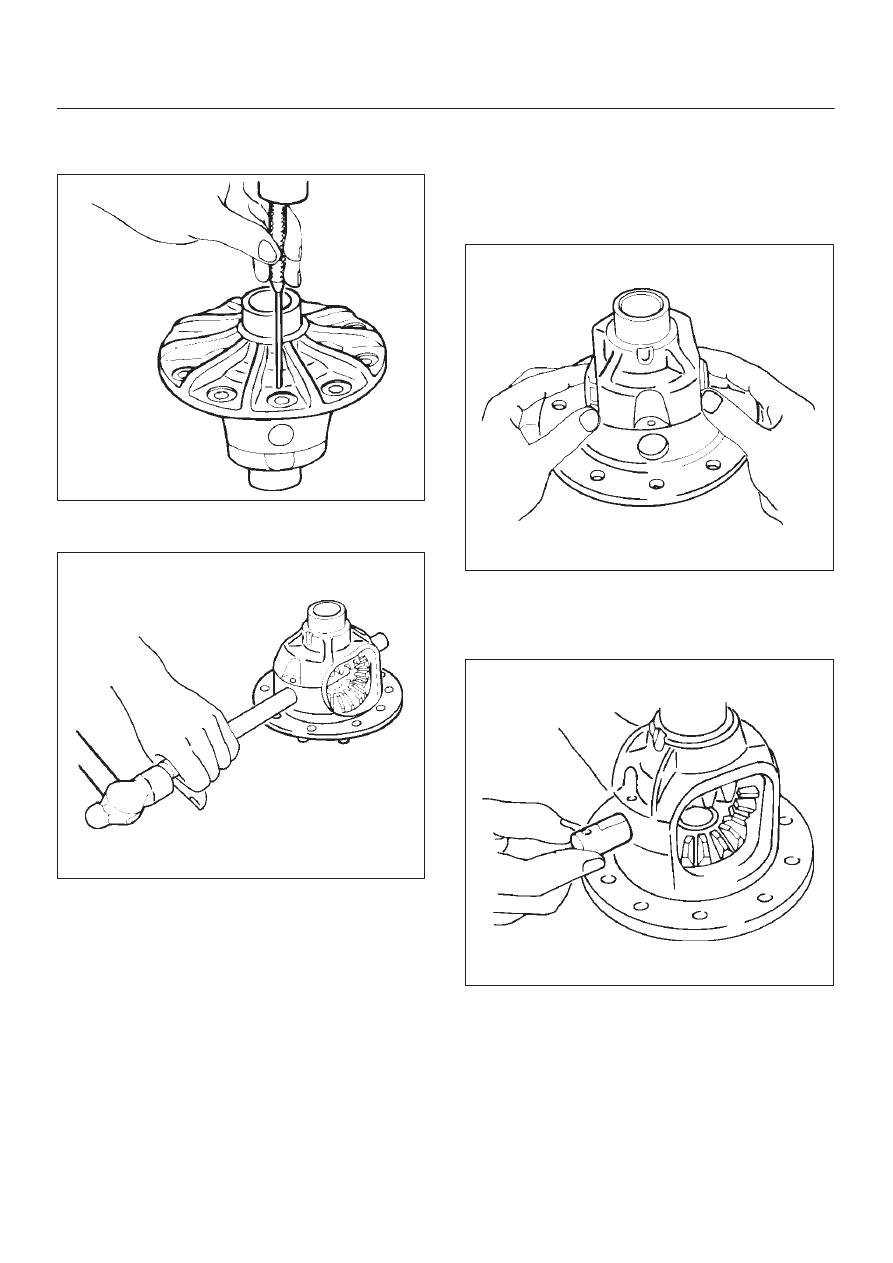

Disassembly

1. Remove lock pin using a small drift.

425RS098

2. Remove the differential shaft by using a soft metal rod

and a hammer.

425RS043

3. Remove pinion mate gear and thrust washer.

4. Remove side gear and thrust washer.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition are

found through inspection.

Check the following parts.

D

Ring gear, pinion gear

D

Bearing

D

Side gear, pinion mate gear, differential shaft

D

Differential case, carrier

D

Thrust washer

D

Oil seal

Reassembly

1. Install side gear with thrust washer.

2. Install the pinion mate gear with thrust washer by

engaging it with the side gears while turning both

pinion mate gears simultaneously in the same

direction.

425RS048

3. Install differential shaft.

1. Be sure to install the differential shaft so that it is in

alignment with the lock pin hole in the differential

case.

425RS049

4. Install lock pin.

After lock pin installation, stake the case to secure the

lock pin.