Isuzu KB P190. Manual - part 913

Battery

Page 6D1-3–12

9

Lock the doors and activate the theft deterrent system to arm the vehicle.

10

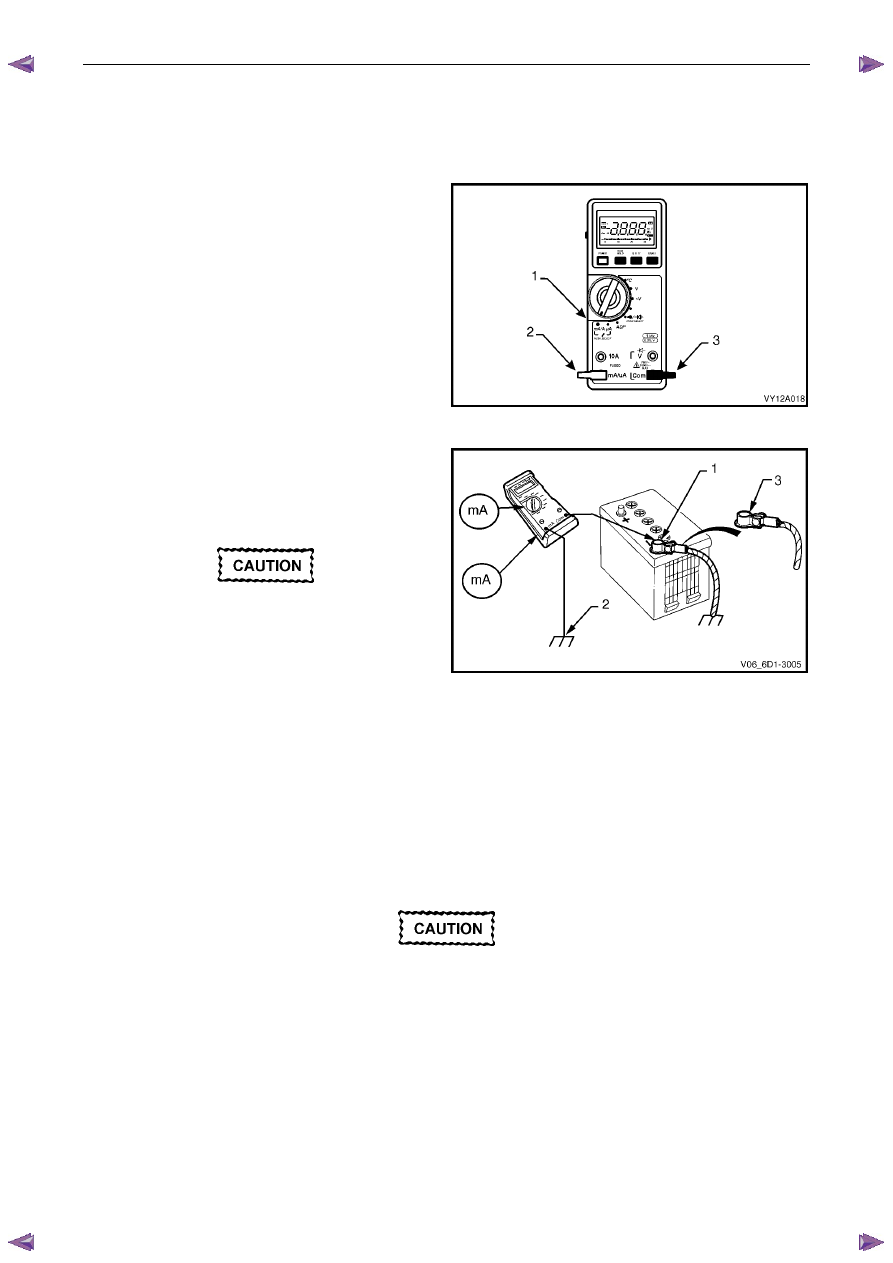

If the multimeter contains fuses, check they are serviceable.

Test Procedure

1

Switch the multimeter to the mA current range (1).

2

Connect the positive test lead (2) to the fused mA

terminal of the multimeter.

3

Connect the negative test (3) lead to the common

terminal of the multimeter.

4

Connect large alligator clips to the ends of both test

leads.

Figure 6D1-3 – 7

5

Connect the negative test lead clip to the threads of

the battery negative terminal clamp (1).

6

Connect the positive lead’s clip to the threads of a

convenient engine bolt (2).

Do not turn on the ignition switch while this

test is in progress. It will blow the

multimeter’s low current fuse.

7

Check the multimeter connections are secure.

8

Disconnect the vehicle’s main electrical earth by

removing the battery negative terminal cable retaining

nut (3) and separating the cable from the battery

clamp.

Figure 6D1-3 – 8

9

Read the vehicle’s battery saver current on the multimeter. The multimeter reading should be within 16 – 30 mA

(fluctuating).

10

If the multimeter reading is higher than specified, refer to Fault Diagnosis in this Section, otherwise restore the

vehicle to its prior condition, refer to Restore in this Section.

Fault Diagnosis

Do not open any doors during this inspection.

If the doors must be opened, reinstall the

battery terminal to the battery clamp to

protect the multimeter's fuse from blowing.

Alternatively, use the higher (10 A) fuse rated

terminal on the multimeter until the source of

the higher current draw has been found.

1

Visually inspect the vehicle for illuminated lamps and components activated by energised relays.

2

If the cause of the excessive current draw is not apparent, remove one fuse (or circuit breaker) at a time to

determine the circuit group that is drawing excess current. Refer to 8A Electrical Body & Chassis for fuse grouping

location.