Isuzu KB P190. Manual - part 712

Engine Mechanical – V6

Page 6A1–71

Page 6A1–71

3.4

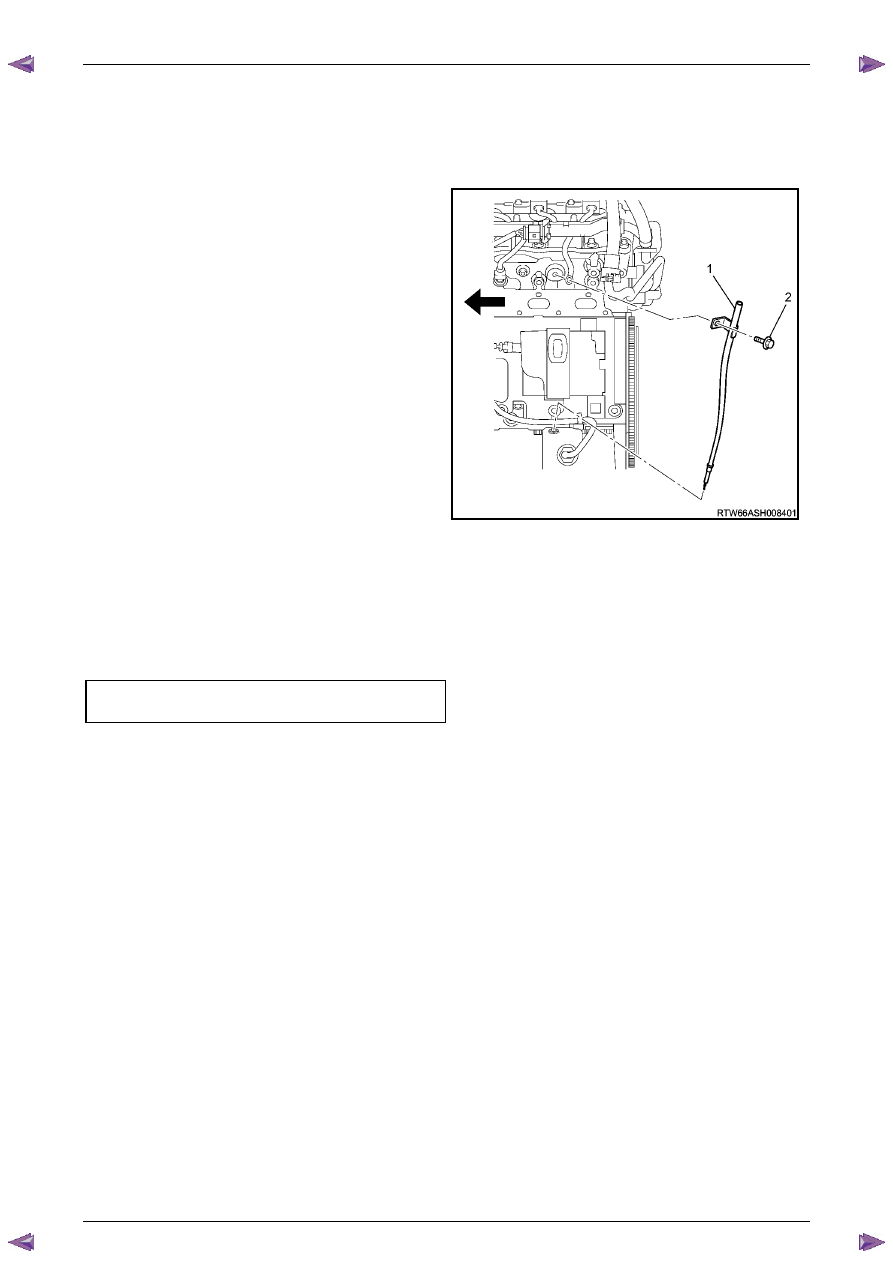

Oil Level Indicator Tube

Remove

1

Remove the oil level indicator from the oil level indicator tube.

2

Remove the bolt (2) attaching the oil level indicator

tube (1) and engine wiring harness retaining bracket.

3

Withdraw the oil level indicator tube from the oil pan.

4

Remove and discard the o-ring at the bottom of the oil

level indicator tube.

Figure 6A1 – 28

Reinstall

Reinstallation of the oil level indicator tube is the reverse of the removal procedure, noting the following:

1

Install a new oil level indicator o-ring.

2

Ensure the attaching bolt passes through the engine wiring harness retaining bracket.

3

Tighten bolt to the correct torque specification.

Oil level indicator tube attaching bolt

torque specification ...................................8.0 – 12.0 Nm