Isuzu KB P190. Manual - part 711

Engine Mechanical – V6

Page 6A1–67

Page 6A1–67

Replace

N O T E

• Quicker and more complete draining will

occur if the engine oil is at normal operating

temperature. However, care must be taken to

avoid scalding from the hot oil.

• It recommended the oil filter be changed at

each engine oil change, refer to

3.2 Oil Filter

.

1

Remove the oil fill cap.

2

To ensure complete draining of the oil pan, raise the front and rear of the vehicle to maintain a level attitude. If not

using a hoist, support the vehicle with safety stands, refer to

Section 0A General Information

.

3

Clean any foreign material from around the oil drain plug and place a suitable, clean drain tray under the engine.

The oil may be hot. Avoid contact with the oil.

Ensure that eyes and skin are protected.

4

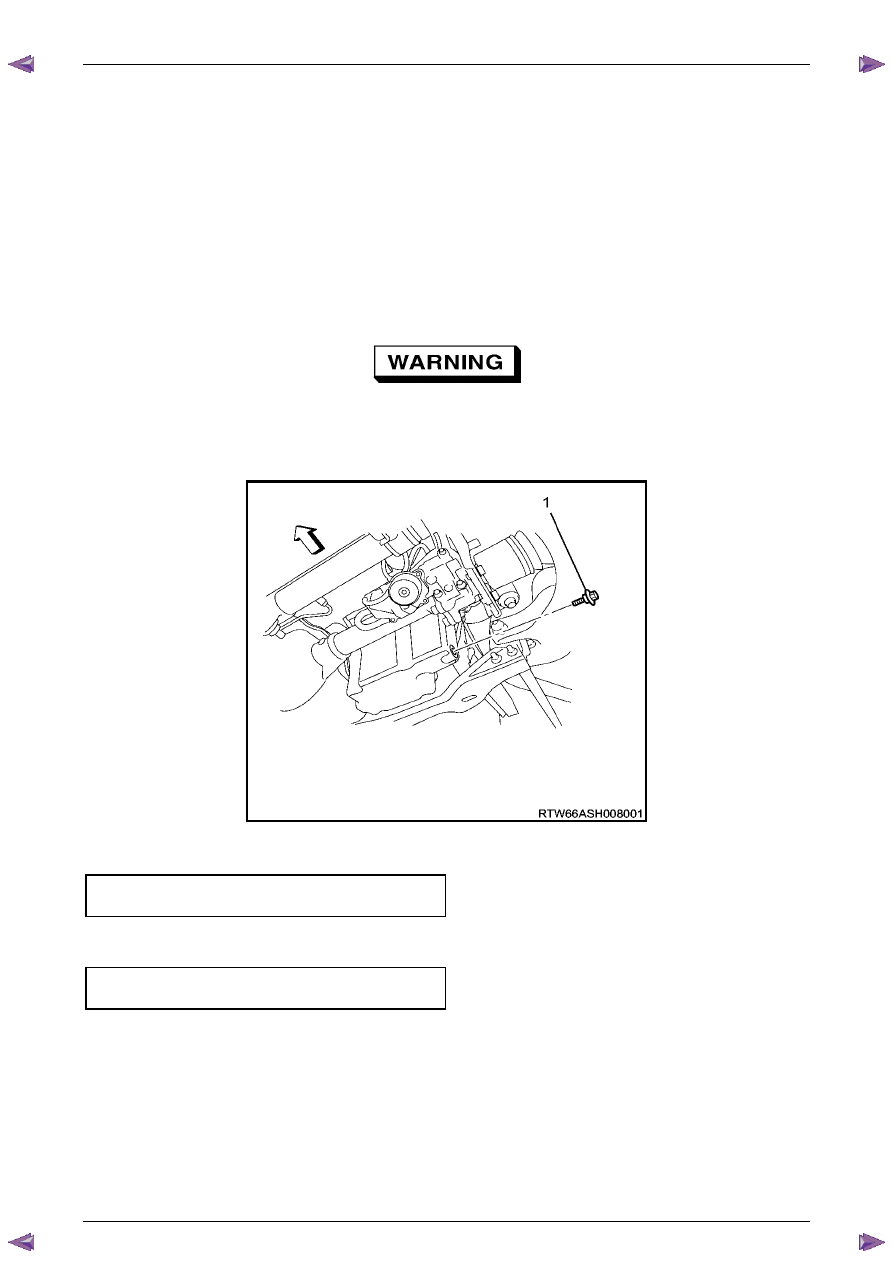

Remove the drain plug (1), taking care to avoid scalding from the hot oil. Allow the oil to drain.

5

Clean and inspect the drain plug threads. If damaged, replace the drain plug.

Figure 6A1 – 24

6

Once the oil has completely drained, reinstall the drain plug and tighten to the correct torque specification.

Oil pan drain plug

torque specification ............................................25.0 Nm

7

Replace the oil filter, refer to

3.2 Oil Filter

.

8

Lower the vehicle to the ground and fill with the specified amount of SAE 5W30 lubricant.

Engine Oil Capacity:

With Oil Filter Change ........................................6.5 litres

9

Install the oil fill cap.

10

Start the engine and check for leaks.