Isuzu KB P190. Manual - part 608

6E–262

ENGINE DRIVEABILITY AND EMISSIONS

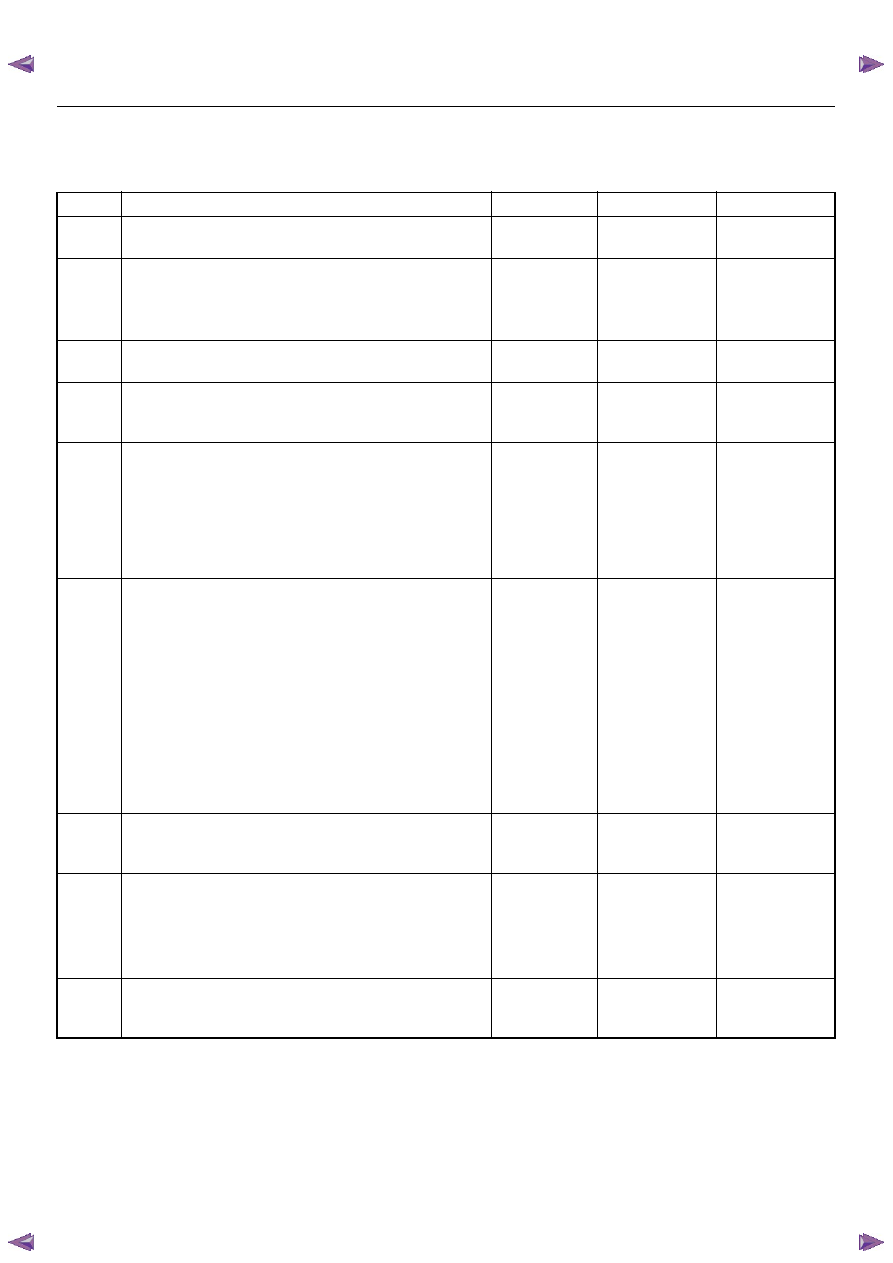

BACKFIRE SYMPTOM

DEFINITIONS: Fuel ignites in the intake manifold, or in the exhaust system, making a loud popping noise.

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to Step 2

Go to OBD

System Check

2

1. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—

Verify repair

Go to Step 3

3

Was a visual/physical check performed?

—

Go to Step 4

Go to Visual /

physical Check.

4

Check for proper ignition voltage output with the spark

tester.

Was a problem found?

—

Verify repair

Go to Step 5

5

1. Remove the spark plugs and check for gas or oil

fouling cracks, wear, improper gap, burned

electrodes, heavy deposits, or improper heat

range.

2. If spark plugs are fouled, the cause of fouling must

be determined before replacing the spark plugs.

Was a problem found?

—

Verify repair

Go to Step 6

6

Visually/physically inspect all spark plug high-tension

cables. Check for the following conditions:

• Verify that the resistance of all spark plug high-

tension cables are less than the specified value.

• Verify that the all spark plug high-tension cables are

correctly fitted to eliminate cross-fitting.

• Verify that the all spark plug high-tension cables are

not arcing to ground.

Spraying the spark plug high-tension cables with a

light mist of water may help locate an intermittent

problem.

Was a problem found?

#1 cyl. 4.4k

Ω

#2 cyl. 3.6k

Ω

#3 cyl. 3.1k

Ω

#4 cyl. 2.8k

Ω

Verify repair

Go to Step 7

7

Check the fuel pressure. Refer to 6E-108 page “Fuel

System Diagnosis” .

Was a problem found?

—

Verify repair

Go to Step 8

8

Check for an intermittent ignition system malfunction:

• Intermittent CKP 58X signal

• Intermittent ignition feed circuit or sensor ground

circuit to the crankshaft position sensor.

Was a problem found?

—

Verify repair

Go to Step 9

9

Refer to 6E-108 page “Fuel System Diagnosis ”

to

determine if there is a problem with fuel delivery.

Was a problem found?

—

Verify repair

Go to Step 10