Isuzu KB P190. Manual - part 606

6E–254

ENGINE DRIVEABILITY AND EMISSIONS

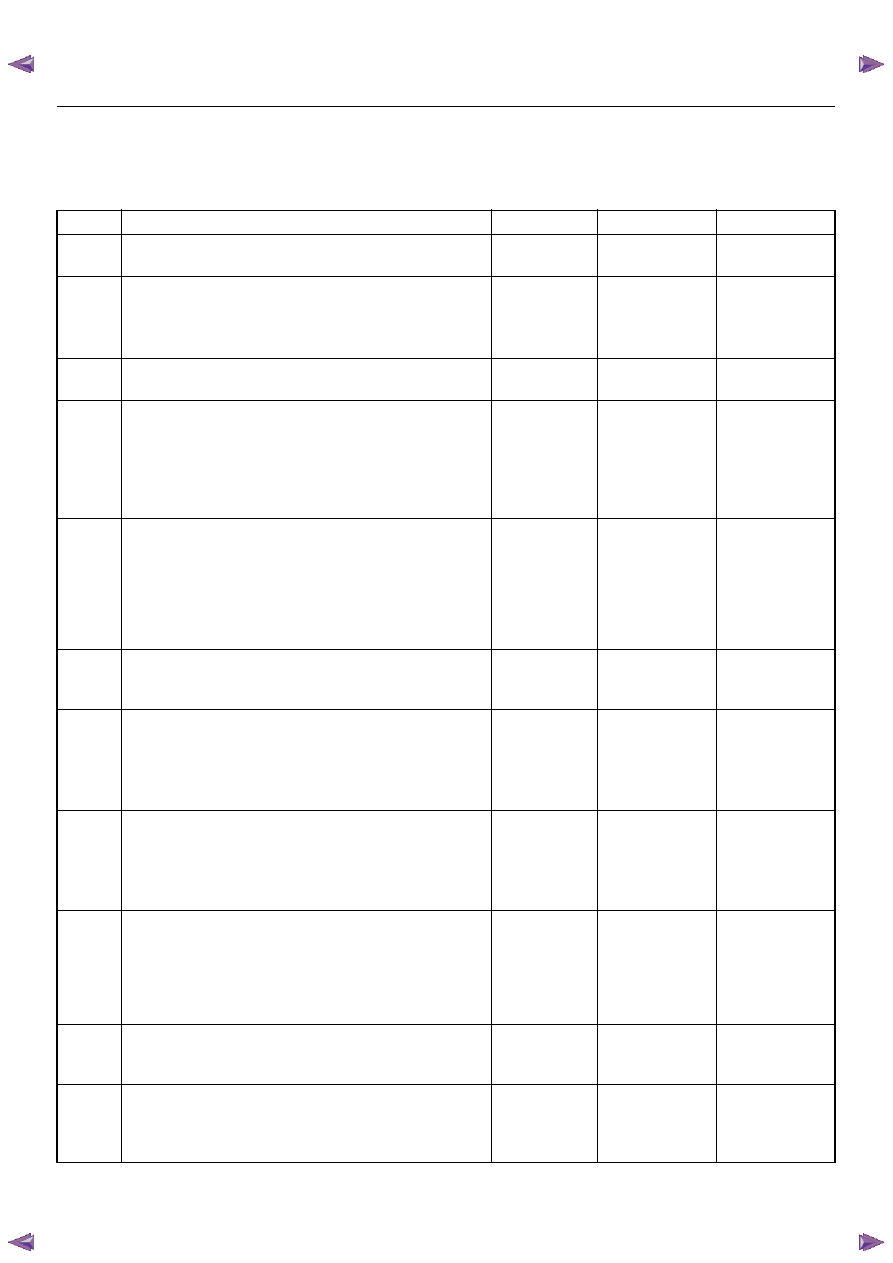

DETONATION/SPARK KNOCK SYMPTOM

DEFINITIONS: A mild to severe ping, usually worse under acceleration. The engine makes a sharp metallic knocking

sound that changes with throttle opening. Prolonged detonation may lead to complete engine tailure.

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to Step 2

Go to OBD

System Check

2

1. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—

Verify repair

Go to Step 3

3

Was a visual/physical check performed?

—

Go to Step 4

Go to Visual /

physical Check.

4

1. If Tech 2 readings are normal (refer to Typical

Scan Data Values) and there are no engine

mechanical faults, fill the fuel tank with a known

quality gasoline.

2. Re-evaluate the vehicle performance.

Is detonation present?

—

Go to Step 5

Verify repair

5

1. Check for obvious overheating problems:

• Low engine coolant

• Restricted air flow to radiator

• Incorrect coolant solution

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to Step 6

6

Check the fuel pressure. Refer to 6E-108 page “Fuel

System Diagnosis” .

Was a problem found?

—

Verify repair

Go to Step 7

7

1. Using a Tech 2, display the MAP sensor value in

comparison with atmosphere temperature.

2. Check for a faulty, plugged, or incorrectly installed

MAP sensor.

Was the problem found?

—

Verify repair

Go to Step 8

8

1. Using a Tech 2, display the ECT sensor and IAT

sensor value and warm up condition compared

with the typical data.

2. Check the specified value or wire.

Was the problem found?

—

Verify repair

Go to Step 9

9

Observe the throttle position display on the Tech 2

while slowly increasing throttle pedal.

Does the throttle position increase steady with

increasing smoothly?

—

Go to Step 10

Refer to

Diagnostic

Trouble Code

P0123 for

further

diagnosis

10

Check the knock sensor wire, shield wire, or

installation condition.

Was a problem found?

—

Verify repair

Go to Step 11

11

Check items that can cause the engine to run lean.

Refer to DTC P1171 “Fuel Supply System Lean

During Power Enrichment”.

Was a problem found?

—

Verify repair

Go to Step 12