Isuzu KB P190. Manual - part 555

6E–50

ENGINE DRIVEABILITY AND EMISSIONS

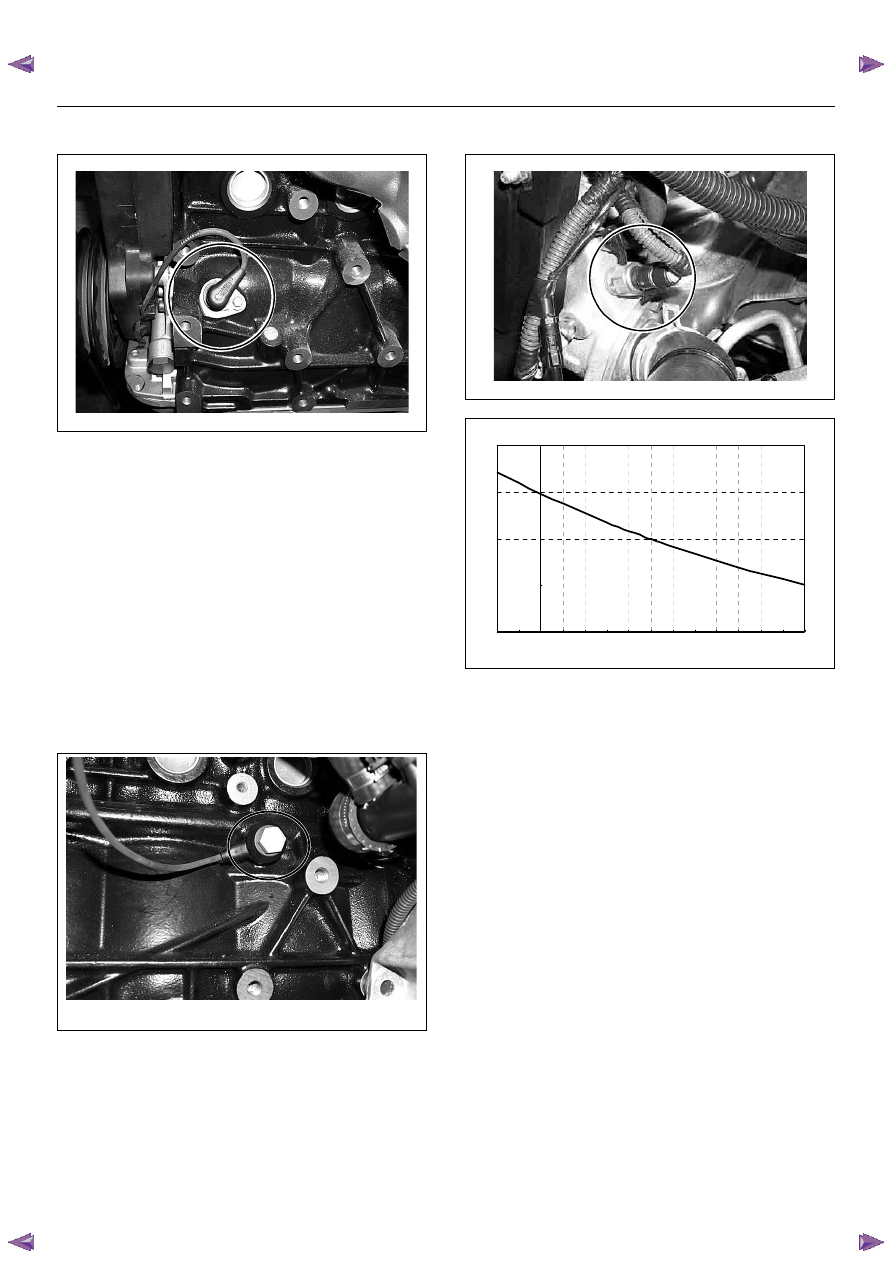

Crankshaft Position (CKP) Sensor

The crankshaft position (CKP) sensor, which sends a

signal necessary for deciding on injection timing to the

ECM, is mounted on the left-hand side of the cylinder

block just back of the A/C compressor.

The crankshaft has a 58 teeth press-fit timing disc, from

which the CKP sensor reads the position of the

crankshaft at all the times. It converts this to an

electrical signal, which it sends to the ECM.

Using the 58 X signals per rotation and the timing-mark

signal sent by the CKP sensor, the ECM is able to

accurately calculate engine speed and crank position.

The ECM converts the 58 X signals into square signals.

This converted signal is sent from the ECM terminal J2-

25 to the tachometer.

Knock Sensor (KS)

The knock sensor (KS) contains an element that

converts detection of knock into an electrical signal, and

is mounted on cylinder block wall.

When the ECM receives a signal that indicates knock,

the ECM orders ignition timing to be adjusted to

compensate.

Engine Coolant Temperature (ECT) Sensor

The ECT sensor is a thermistor. A temperature changes

the resistance value. And it changes voltage. In other

words it measures a temperature value. It is installed on

the coolant stream. Low coolant temperature produces

a high resistance.

The ECM supplies 5 volts signal to the ECT sensor

through resisters in the ECM and measures the voltage.

The signal voltage will be high when the engine

temperature is cold, and it will be low when the engine

temperature is hot.

Characteristic of ECT Sensor -Ref erence-

10

100

1000

10000

100000

-20

-10

0

10

20

30

40

50

60

70

80

90

100

110

120

Coolant Temp. (deg. C) (Tech2 Reading)

R

e

si

st

ance (

ohm

) (

S

ol

id

Li

ne)