Isuzu KB P190. Manual - part 518

6A-58 ENGINE MECHANICAL (C24SE)

Clean

Plastigage from journals.

Lightly coat journals and bearings with engine oil.

Installation

Install bearing cap and shell using new bolts.

Torque - Angle Method

Main bearing cap bolt - 60 N

⋅m (6.1 kgf⋅m) +40° to 50°.

Con-rod bearing cap bolts - 35 N

⋅m (3.9 kgf⋅m) +45°.

2.Micrometer and gauge method.

Crankshaft removed.

Installation

1. Install caps and bearing shells to con-rods and cylinder

block.

Measure

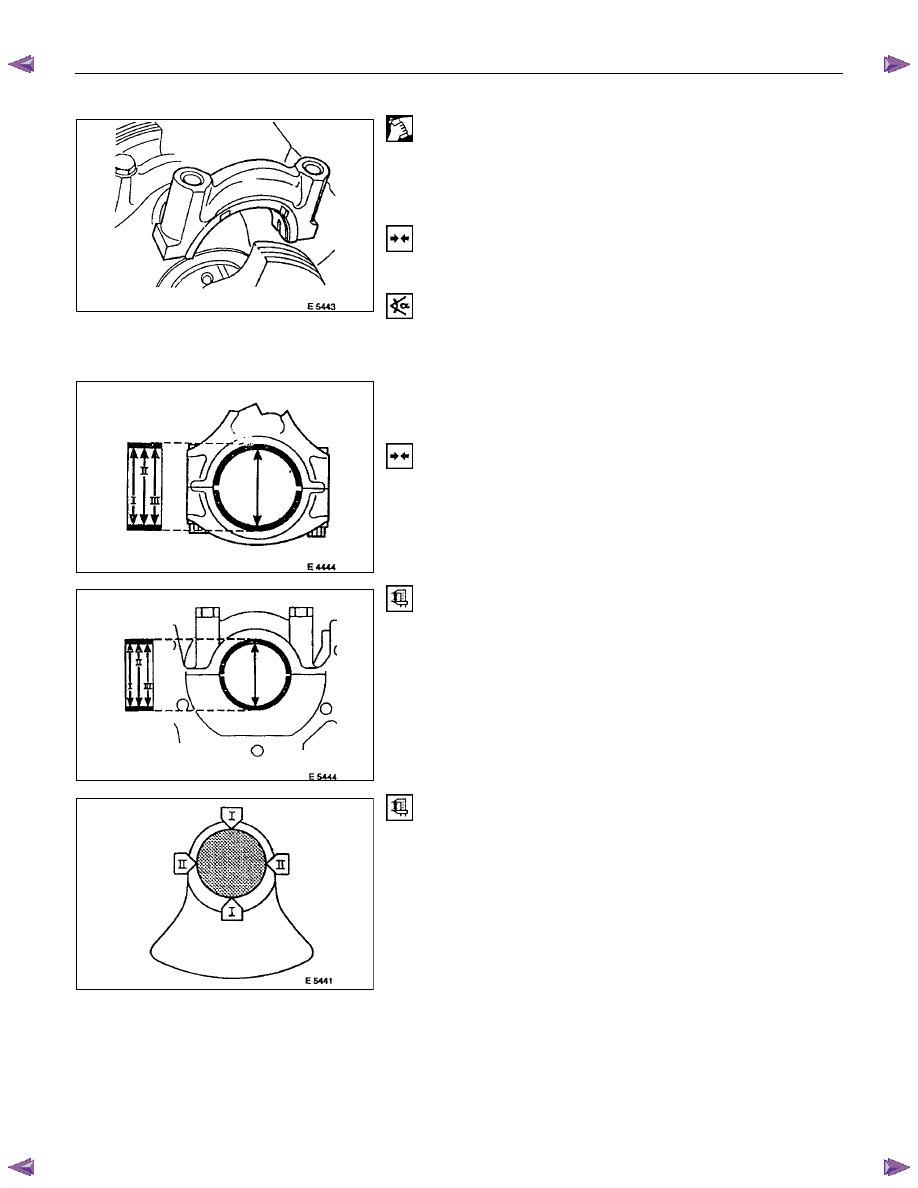

Con-rod and main bearing diameters at three points I, II, III

(arrowed).

Divide the sum of the three measurements by three to obtain a

mean diameter.

The top illustration shows con-rod measuring points.

The second illustration shows main bearing measuring points.

Measure

Crankshaft main and con-rod bearing journals at points I and

II. Divide the sum of both measurements to obtain a mean

diameter.

Crankshaft must be replaced if mean diameter of main or con-

rod journals is below specified limit - see "Technical Data".

If crankshaft is serviceable subtract crankshaft mean journal

diameters from corresponding shell bearing mean diameters to

determine bearing clearance.

Permissible main bearing clearance - 0.015 to 0.04mm/0.0006

to 0.002in.

Permissible con-rod bearing clearance - 0.006 to

0.031mm/0.002 to 0.001in.