Isuzu KB P190. Manual - part 422

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-71

DTC P0045 (Flash Code 33)

Circuit Description

The position of the turbocharger nozzle is controlled by

the ECM. The ECM utilizes a turbocharger nozzle

control solenoid valve and a boost pressure sensor to

control the turbocharger nozzles. When the engine is

not under load, the turbocharger nozzles are in an open

position, or no boost condition. When the engine is

under load, the ECM commands the control solenoid

valve to close the turbocharger nozzles, thus

increasing the boost. The ECM will vary the boost

dependant upon the load requirements of the engine.

The ECM uses a pulse width modulation (PWM) on the

control circuit to open and control the solenoid valve. If

the ECM detects an open circuit or short circuit on the

solenoid valve circuit, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

Either of following condition is met:

• The ECM detects a low voltage condition on the

turbocharger nozzle control solenoid circuit when

the solenoid is commanded OFF.

• The ECM detects a high voltage condition on the

turbocharger nozzle control solenoid circuit when

the solenoid is commanded ON.

Action Taken When the DTC Sets

• The ECM illuminates the MIL when the diagnostic

runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits cruise control.

Condition for Clearing the DTC

• Refer to DTC Type Definitions for Condition for

Clearing the MIL/ DTC - Type A.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Test description

The number below refers to the step number on the

Circuit/ System Testing.

4. If the solenoid control circuit between the ECM and

the solenoid is normal, the test lamp changes from

Bright to Dim when commanded from Increase to

Decrease.

Schematic Reference: Vacuum Hose Routing

Diagram and Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

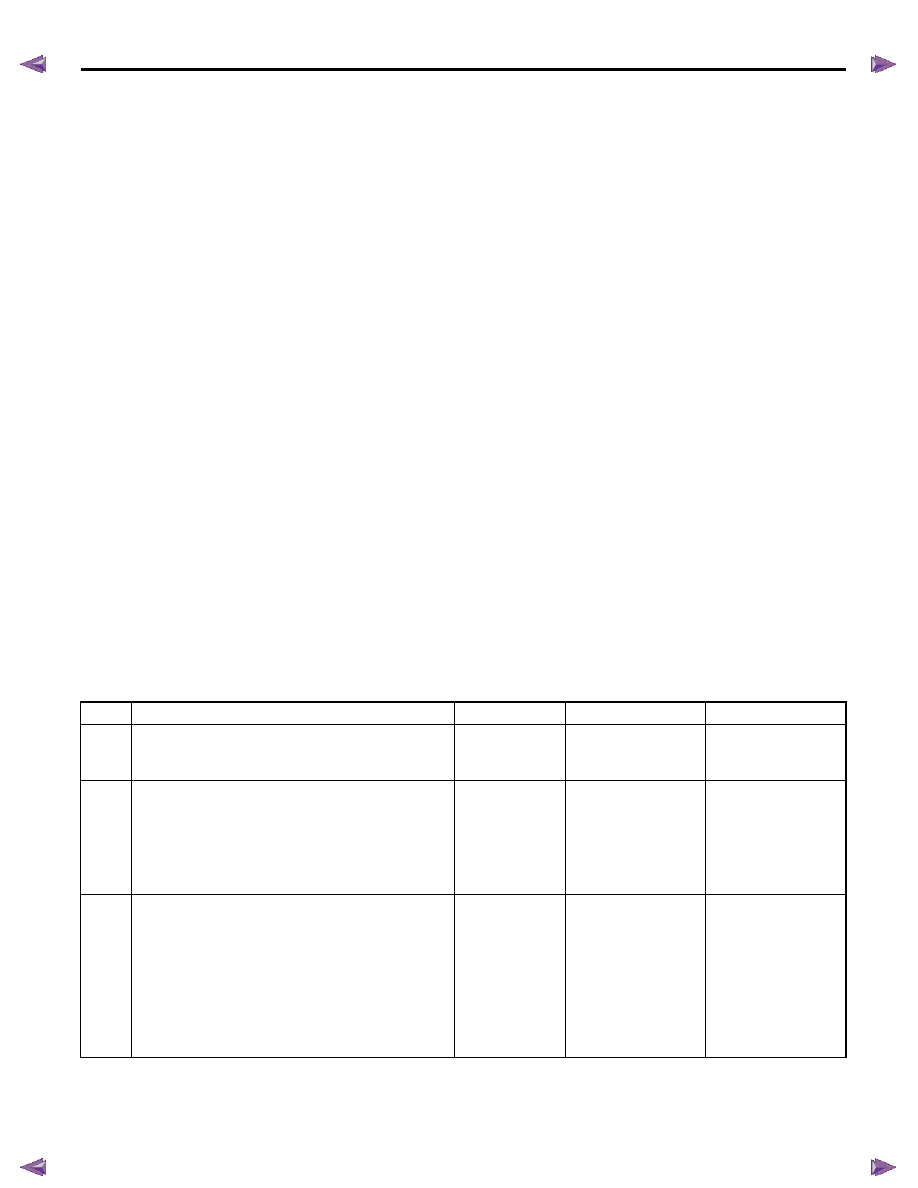

Circuit/ System Testing DTC P0045

Step

Action

Value(s)

Yes

No

1

Did you perform the Diagnostic System Check -

Engine Controls?

—

Go to Step 2

Go to Diagnostic

System Check -

Engine Controls

2

1.

Install a scan tool.

2.

Turn OFF the ignition for 30 seconds.

3.

Start the engine.

4.

Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition?

—

Go to Step 3

Go to Diagnostic

Aids

3

1.

Turn OFF the ignition.

2.

Disconnect the turbocharger nozzle control

solenoid valve harness connector.

3.

Connect a test lamp between the ignition

voltage feed circuit (pin 2 of E-106) and a

known good ground.

4.

Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate?

—

Go to Step 4

Go to Step 5