Isuzu KB P190. Manual - part 420

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-63

Engine Cranks but Does Not Run

Description

The Engine Cranks but Does Not Run diagnostic table

is an organized approach to identifying a condition that

causes an engine to not start. The diagnostic table

directs the service technician to the appropriate system

diagnosis. The diagnostic table assumes the following

conditions are met:

• The battery is completely charged and terminals

are cleaned and tight.

• The engine cranking speed is normal.

• There is adequate fuel in the fuel tank.

• There is no fuel leak in the fuel line.

• There is no air in the fuel line.

• Filters (air, fuel) are clean.

• Fuse and slow blow fuse are normal.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Test Description

The number below refers to the step number on the

Circuit/ System Testing.

5. If the fuel rail pressure (FRP) regulator low side

circuits between the ECM and the FRP regulator are

shorted to ground, FRP Regulator Feedback will be

approximately 400mA lower as compared with normal.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

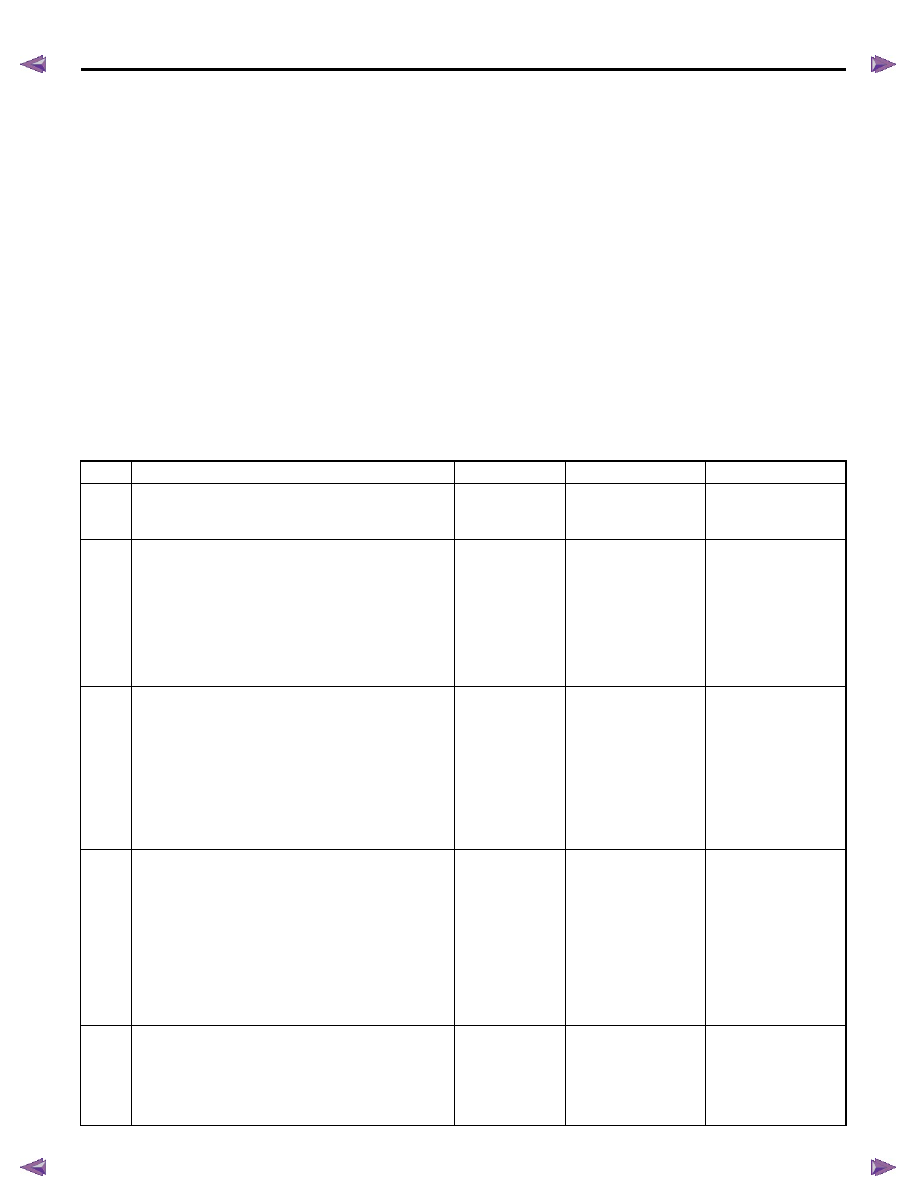

Circuit/ System Testing Engine Cranks but Does Not Run (1of 2)

Step

Action

Value(s)

Yes

No

1

Did you perform the Diagnostic System Check -

Engine Controls?

—

Go to Step 2

Go to Diagnostic

System Check -

Engine Controls

2

1.

Install a scan tool.

2.

Turn OFF the ignition for 30 seconds.

3.

Crank the engine for the specified amount of

time.

4.

Monitor the DTC Information with a scan tool.

Does the scan tool display any DTCs that failed this

ignition?

15 seconds

Go to Applicable

DTC

Go to Step 3

3

1.

Turn OFF the ignition.

2.

Wait 1 minute for the fuel pressure to bleed

down from the fuel rail.

3.

Turn ON the ignition, with the engine OFF. DO

NOT start the engine.

4.

Observe the Fuel Rail Pressure parameter

with a scan tool.

Does the scan tool indicate the specified value?

0 MPa (0 psi)

Go to Step 4

Go to Step 6

4

Notice: If the vehicle has run out of fuel, air may

be trapped in the fuel system.

1.

Make sure the fuel tank have adequate fuel

and the fuel quality is good (take a sample).

2.

Observe the Fuel Rail Pressure parameter on

the scan tool while cranking over the engine

for 5 seconds.

Does the scan tool indicate more than the specified

value during crank?

20 MPa (2,900

psi)

Go to Step 9

Go to Step 5

5

Observe the FRP Regulator Feedback parameter

on the scan tool while cranking over the engine for

5 seconds.

Does the scan tool indicate more than the specified

value during crank?

1500 mA

Go to 2 of 2 Step 1

Go to Step 8