Isuzu KB P190. Manual - part 288

6E-118 Engine Control System (4JH1)

DTC P0243 (Symptom Code 6) (Flash Code 64)

Circuit Description

The engine control module (ECM) controls the

turbocharger wastegate valve based on the barometric

pressure in order to reduce turbocharger spinning

speeds at high altitude area. The ECM controls the

turbocharger wastegate valve diaphragm by acting the

regulated vacuum pressure via controlling the solenoid

valve. The vacuum pressure sensor monitors the

regulated vacuum pressure to the turbocharger

wastegate valve. The ECM calculates desired vacuum

pressure and it compares the calculated desired

vacuum pressure to the actual value to determine the

solenoid valve position. When the actual vacuum

pressure is higher than the desired value, the solenoid

valve is closed to decrease the vacuum pressure.

The mass air flow (MAF) sensor monitors boost

pressure by monitoring the amount of mass air flow. An

expected MAF amount should be detected while the

engine running. If the ECM detects the actual MAF

amount is higher than desired MAF amount, this DTC

will set. This indicates excessive high boost pressure

and turbocharger wastegate valve most likely did not

active.

Condition for Running the DTC

• The ignition switch is ON.

• The engine coolant temperature (ECT) is between

-50°C (-58 °F) and 150°C (302°F).

• The EGR solenoid valve control is OFF.

• The MAF sensor DTC P0100 is not set.

• The vacuum pressure sensor DTC P0105 is not

set.

• The intake air temperature (IAT) sensor DTC

P0110 is not set.

Condition for Setting the DTC

• The ECM detects that the MAF amount is 56

mg/strk higher than the desired MAF for 3

seconds. This indicates an excessive high boost

pressure.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicator

lamp (MIL) when the diagnostic runs and fails.

• The ECM limits fuel injection quantity.

• The ECM uses an EGR solenoid valve control

substitution of 10%.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

• Check the wastegate for a sticking or stuck

condition. Refer to Wastegate Operation in the

Engine Mechanical section.

• Use the scan tool to verify the integrity of the MAF

sensor signal. Compare the sensor values under

all load conditions for an excessively high value.

Use the scan tool data list values for nominal

sensor readings.

• The fuel with which gasoline was mixed may set

this DTC.

• A sticking or intermittently sticking the EGR valve

may set this DTC.

• Misrouted vacuum hoses may set this DTC.

DTC P0243 (Symptom Code 6) (Flash Code 64)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

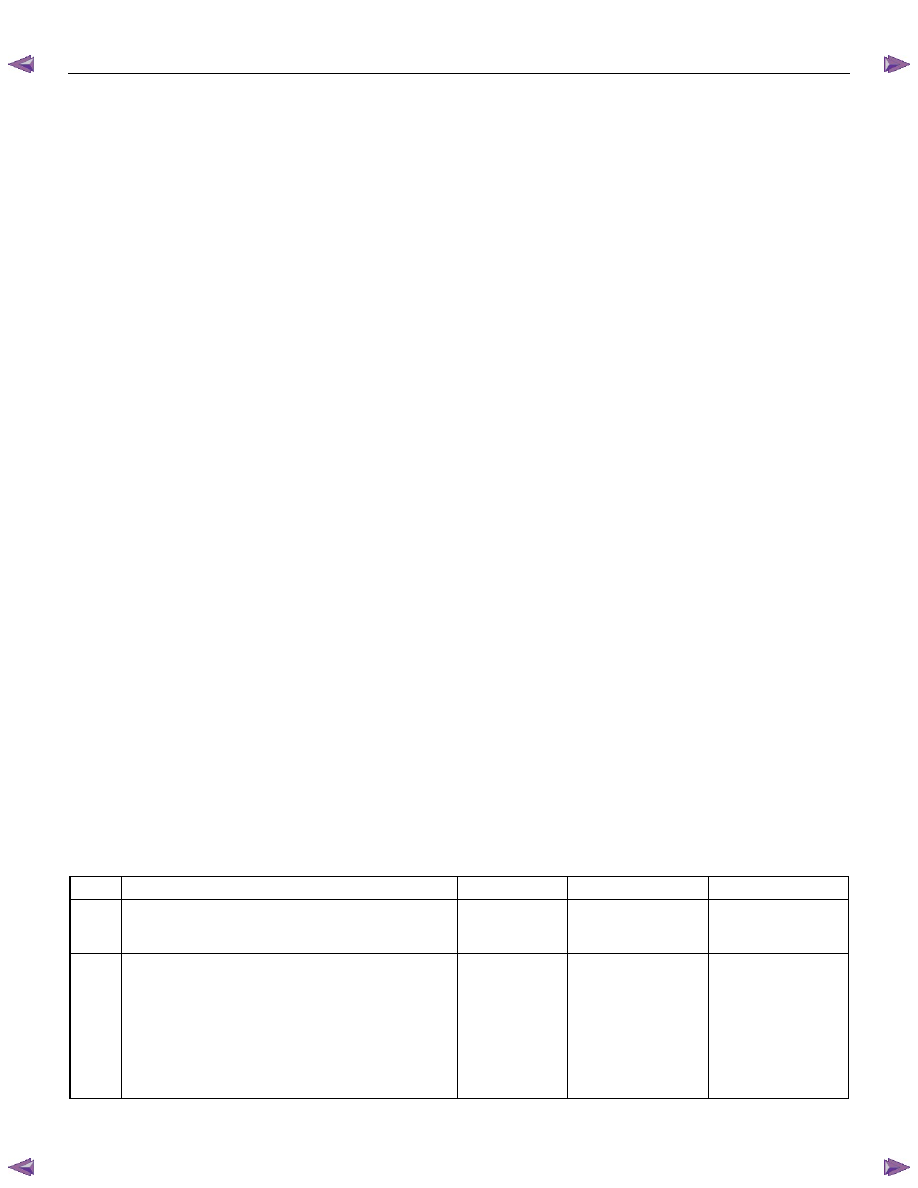

Step Action

Value(s)

Yes

No

1

Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2

Go to Diagnostic

System Check-

Engine Controls

2

1. Install the scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine and let idle for 30 seconds.

4. Monitor the Diagnostic Trouble Code (DTC)

Information with the scan tool.

Is DTC P0105 (Symptom Code 1, 2, 7 or 9), P0243

(Symptom Code 3, 4, 5 or 8) or P0400 (Symptom

Code 3, 4, 5 or 8) set?

Go to Applicable

DTC

Go to Step 3