Isuzu KB P190. Manual - part 208

ENGINE MECHANICAL 6A – 27

111R300001

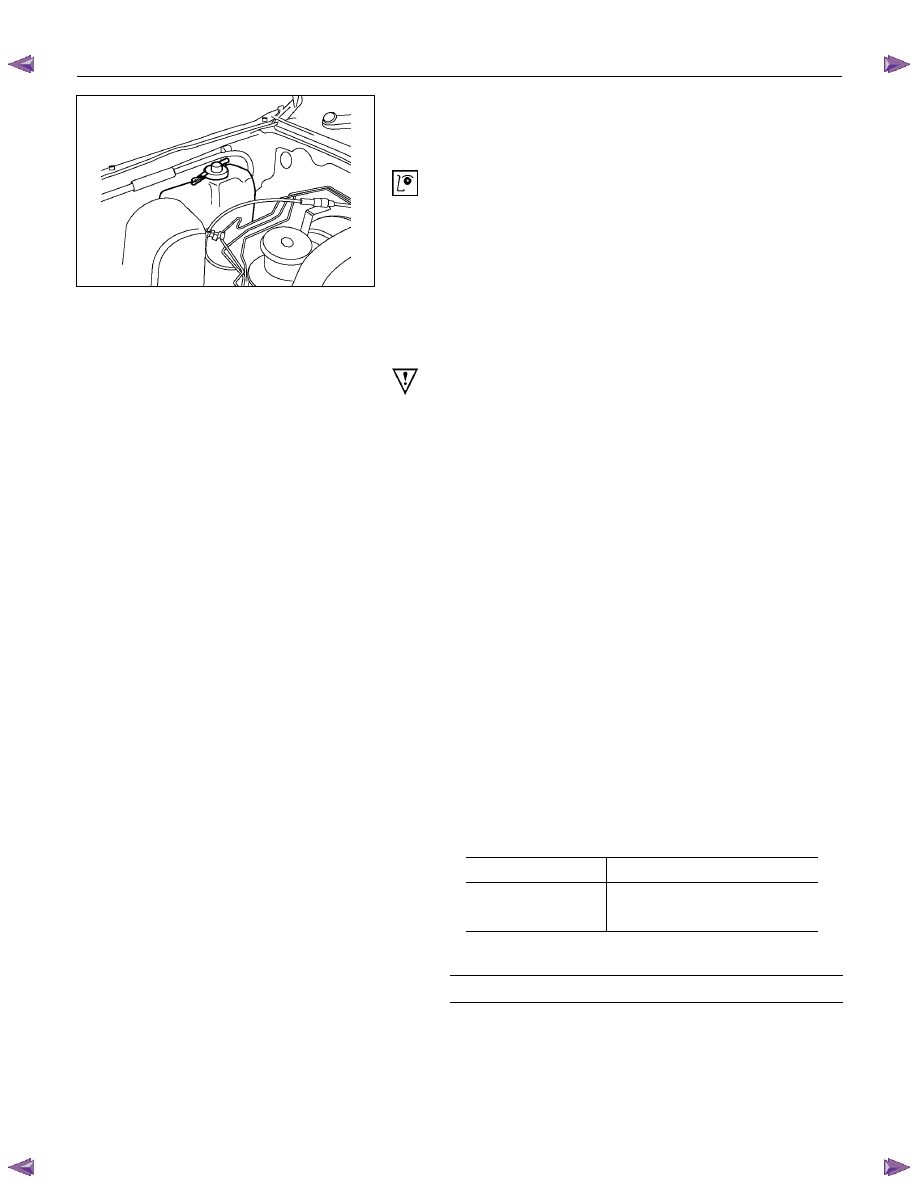

COOLING SYSTEM

Coolant Level

Check the coolant level and replenish the radiator reserve

tank as necessary.

If the coolant level falls below the “MIN” line, carefully

check the cooling system for leakage. Then add enough

coolant to bring the level up to the “MAX” line.

Engine coolant Filling up procedure

1. Make sure that the engine is cool.

Warning:

When the coolant is heated to a high temperature, be

sure not to loosen or remove the rediator cap.

Otherwise you might get scalded by hot vapor or

boiling water.

To open the radiator cap, put a piece of thick cloth on

the cap and loosen the cap slowly to reduce the

pressure when the coolant has become cooler.

2. Open rediator cap pour coolant up to filler neck

3. Pour coolant into reservoir tank up to “MAX” line

4. Tighten radiator cap and start the engine. After idling

for 2 to 3 minutes, stop the engine and reopen radiator

cap. If the water level is lower, replenish.

5. After replenish the coolant tighten radiator cap, warm

up the engine at about 2000 rpm. Set heater

adjustment to the highest temperature position, and let

the coolant circulate also into heater water system.

6. Check to see the thermometer, continuously idling 5

minutes and stop the engine.

7. When the engine has been cooled, check filler neck

for water level and replenish if required. Should

extreme shortage of coolant is found, check the

coolant system and reservoir tank hose for leakage.

8. Pour coolant into the reservoir tank up to “MAX” line.

Engine Coolant Total Capacity

Lit (U.S / UK gal)

4JA1 / TC

9.4 (2.5 / 2.1)

4JH1TC

M/T: 10.1 (2.7 / 2.2)

A/T: 10.0 (2.6 / 2.2)

Mixing Ratio (Anti-Freeze Solution/Water)

50 %