Content .. 1145 1146 1147 1148 ..

Isuzu KB P190. Manual - part 1147

7B-24 MSG MODEL

Ball bearing

J-22912-01

Important Operations

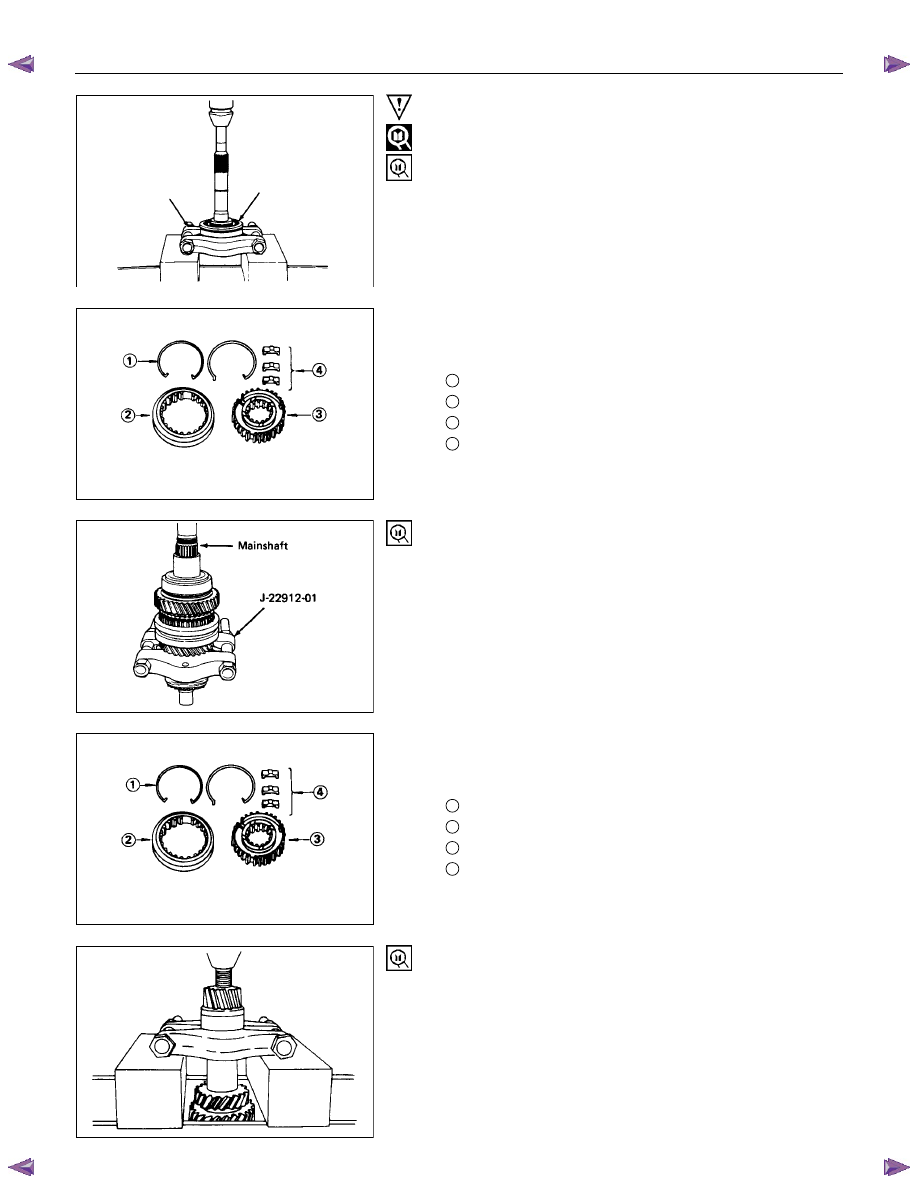

1. Top Gear Shaft Snap Ring

2. Top Gear Shaft

3. Ball Bearing

1) Use a pair of snap ring pliers to remove the snap ring.

2) Use a bench press and a bearing remover to remove the

ball bearing.

Bearing Remover : 5-8840-0015-0 (J-22912-01)

7. 3rd - 4th Synchronizer Assembly

1) Remove the synchronizer assembly as a set.

2) Disassemble the synchronizer assembly.

1

Springs

2

Sleeve

3

Clutch Hub

4

Inserts

11. Mainshaft Ball Bearing

Use a bench press and a bearing remover to remove the ball

bearing.

Bearing Remover : 5-8840-0015-0 (J-22912-01)

17. 1st - 2nd Synchronizer Assembly

1) Remove the synchronizer assembly as a set.

2) Disassemble the synchronizer assembly.

1

Springs

2

Sleeve

3

Clutch Hub

4

Inserts

22. Rear Ball Bearing

24. Front Ball Bearing

Use a bench press and a bearing remover to remove the ball

bearing.

Bearing Removar : 5-8840-0015-0 (J-22912-01)