Infiniti QX56 (JA60). Manual - part 805

RSU-30

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

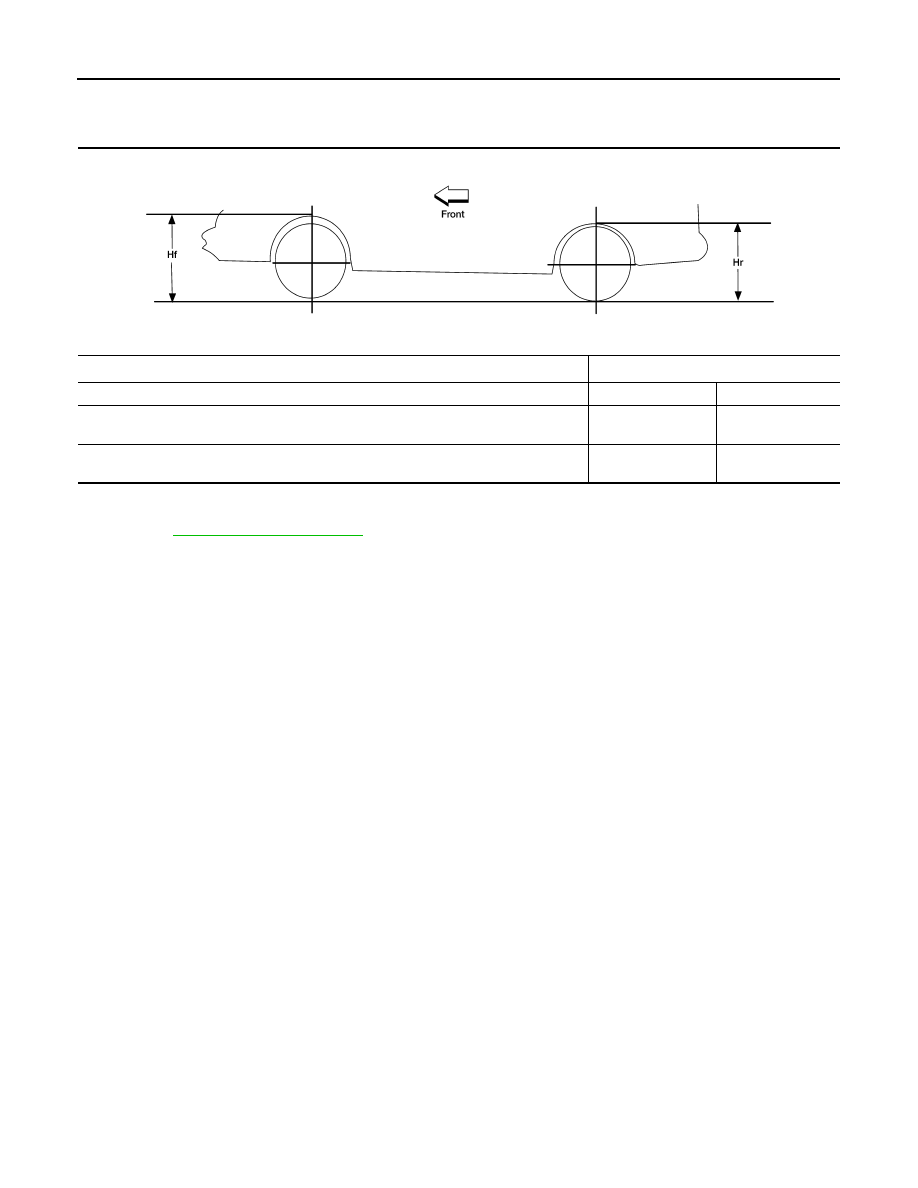

Wheelarch Height (Unladen*

1

)

INFOID:0000000005148144

Unit: mm (in)

*1: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: Verify the vehicle height. If vehicle height is not within

± 10 mm (0.39 in) of the specification, perform the control unit initialization pro-

cedure. Refer to

RSU-26, "Initialization Procedure"

Suspension type

Air leveling*

2

Applied model

2WD

4WD

Front wheelarch height (Hf)

920

(36.22)

937

(36.89)

Rear wheelarch height (Hr)

917

(36.10)

937

(36.89)

LEIA0085E