Infiniti QX56 (JA60). Manual - part 550

FSU-6

< ON-VEHICLE MAINTENANCE >

ON-VEHICLE SERVICE

ON-VEHICLE MAINTENANCE

ON-VEHICLE SERVICE

Front Suspension Parts

INFOID:0000000005148108

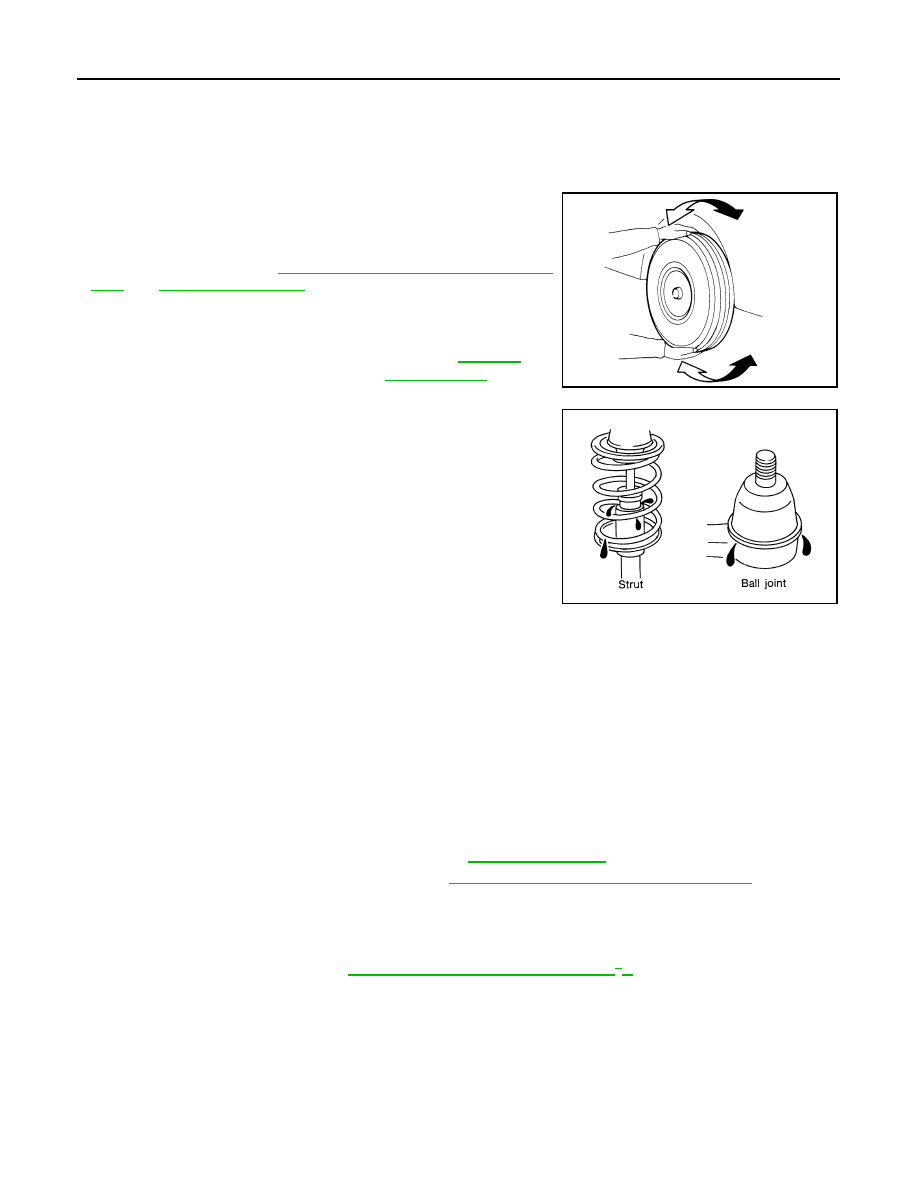

Check front suspension parts for excessive play, cracks, wear and

other damage.

• Shake each front wheel to check for excessive play.

If looseness is noted, inspect wheel bearing end play, then check

ball joint end play. Refer to

FAX-6, "On-Vehicle Inspection and Ser-

• Make sure that the cotter pin is inserted (4WD only).

• Retighten all nuts and bolts to the specified torque.

• Check shock absorber for oil leakage and other damage.

• Check suspension ball joint for grease leakage and ball joint dust

cover for cracks and other damage.

Front Wheel Alignment

INFOID:0000000005148109

PRELIMINARY INSPECTION

WARNING:

Always adjust the alignment with the vehicle on a flat surface.

NOTE:

If alignment is out of specification, inspect and replace any damaged or worn suspension parts before making

any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, coolant, and lubricant are full; and that the spare tire, jack, hand tools and mats are in

their designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer to

.

4. Check the wheel bearing axial end play. Refer to

FAX-6, "On-Vehicle Inspection and Service"

.

5. Check the shock absorbers for leaks or damage.

6. Check each mounting point of the suspension components for any excessive looseness or damage.

7. Check each link, arm, and the rear suspension member for any damage.

8. Check the vehicle height. Refer to

FSU-24, "Wheelarch Height (Unladen*

.

• Verify the level using Consult-III memory register 1103 and set to 0

± 10 mm (0 ± 0.39 in) as necessary.

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

• This type of alignment is recommended for any NISSAN vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be capable of accepting any NISSAN vehicle.

• The alignment machine should be checked to ensure that it is level.

Suspension component torques : Refer to

.

SMA525A

SFA392B