Infiniti QX56 (JA60). Manual - part 314

SERVICE DATA AND SPECIFICATIONS (SDS)

DLN-179

< SERVICE DATA AND SPECIFICATIONS (SDS)

[ATX14B]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

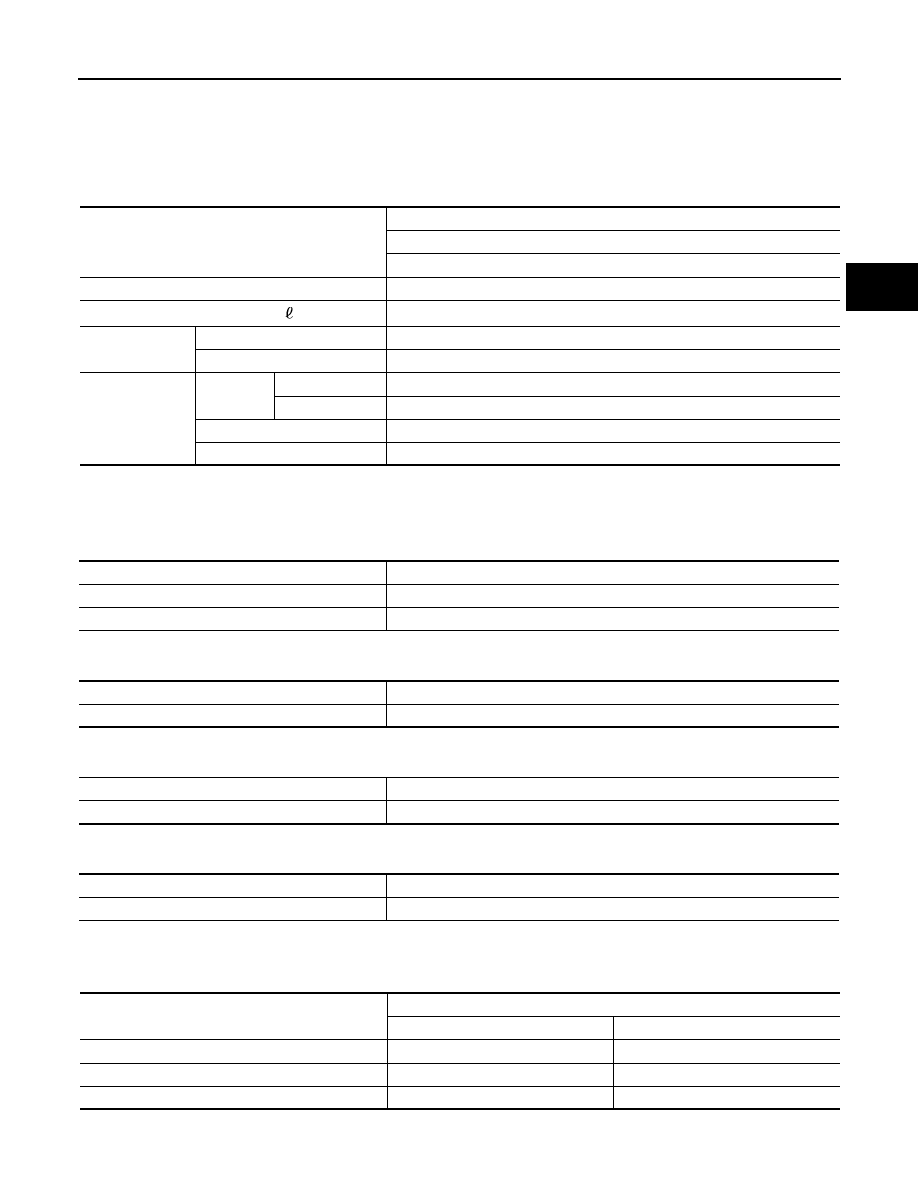

General Specification

INFOID:0000000005148896

Inspection and Adjustment

INFOID:0000000005148897

CLEARANCE BETWEEN INNER GEAR AND OUTER GEAR

Unit: mm (in)

CLUTCH

Unit: mm (in)

PINION GEAR END PLAY

Unit: mm (in)

CLEARANCE BETWEEN SHIFT FORK AND SLEEVE

Unit: mm (in)

SELECTIVE PARTS

Sub-oil Pump

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.

Applied model

4WD

VK56DE

A/T

Transfer model

ATX14B

Fluid capacity (Approx.)

(US qt, lmp qt)

3.0 (3-1/8, 2-5/8)

Gear ratio

High

1.000

Low

2.625

Number of teeth

Planetary

gear

Sun gear

57

Internal gear

91

Front drive sprocket

38

Front drive shaft

38

Item

Specification

Sub-oil pump

0.015 - 0.035 (0.0006 - 0.0014)

Main oil pump

0.015 - 0.035 (0.0006 - 0.0014)

Item

Limit value

Drive plate

1.4 (0.055)

Item

Standard

Pinion gear end play

0.1 - 0.7 (0.004 - 0.028)

Item

Standard

Shift fork and sleeve

Less than 0.36 (0.0142)

Gear thickness

Part number*

Inner gear

Outer gear

9.27 - 9.28 (0.3650 - 0.3654)

31346 0W462

31347 0W462

9.28 - 9.29 (0.3654 - 0.3657)

31346 0W461

31347 0W461

9.29 - 9.30 (0.3657 - 0.3661)

31346 0W460

31347 0W460