Infiniti M35/M45 Y50. Manual - part 608

DTC P0075, P0081 IVT CONTROL SOLENOID VALVE

EC-905

[VK45DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

4.

CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE

Refer to

EC-905, "Component Inspection"

OK or NG

OK

>> GO TO 5.

NG

>> Replace intake valve timing control solenoid valve.

5.

CHECK INTERMITTENT INCIDENT

Refer to

EC-857, "TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT"

>> INSPECTION END

Component Inspection

NBS005C3

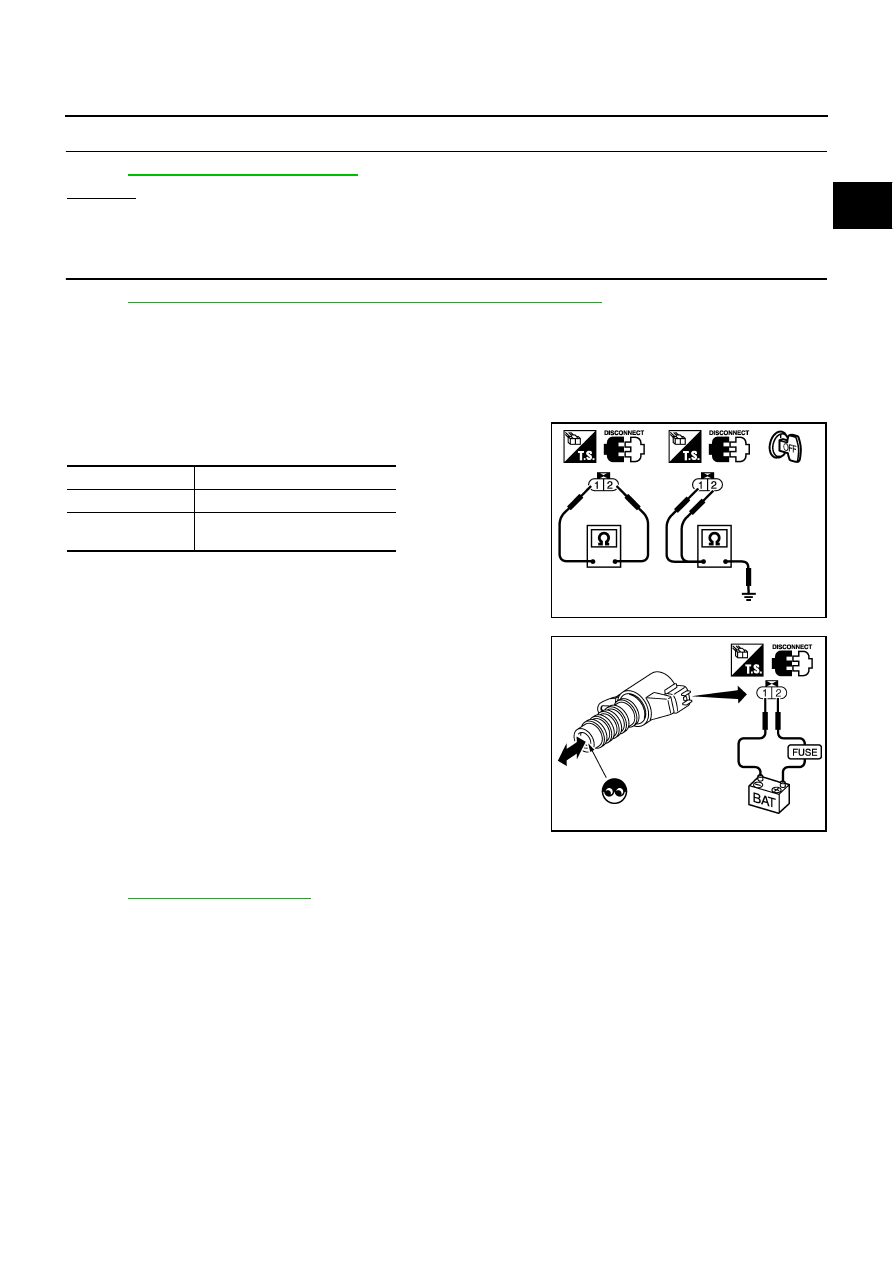

INTAKE VALVE TIMING CONTROL SOLENOID VALVE

1.

Disconnect intake valve timing control solenoid valve harness connector.

2.

Check resistance between intake valve timing control solenoid

valve terminals as follows.

If NG, replace intake valve timing control solenoid valve.

If OK, go to next step.

3.

Remove intake valve timing control solenoid valve.

4.

Provide 12V DC between intake valve timing control solenoid

valve terminals and then interrupt it. Make sure that the plunger

moves as shown in the figure.

CAUTION:

Do not apply 12V DC continuously for 5 seconds or more.

Doing so may result in damage to the coil in intake valve

timing control solenoid valve.

If NG, replace intake valve timing control solenoid valve.

NOTE:

Always replace O-ring when intake valve timing control

solenoid valve is removed.

Removal and Installation

NBS005C4

INTAKE VALVE TIMING CONTROL SOLENOID VALVE

Refer to

Terminals

Resistance

1 and 2

7.0 - 7.5

Ω

[at 20

°

C (68

°

F)]

1 or 2 and ground

∞Ω

(Continuity should not exist)

PBIB0193E

PBIB2275E