Infiniti M35/M45 Y50. Manual - part 155

REFRIGERANT LINES

ATC-171

C

D

E

F

G

H

I

K

L

M

A

B

ATC

CHECKING PROCEDURE

To prevent inaccurate or false readings, make sure there is no refrigerant vapor, shop chemicals, or cigarette

smoke in the vicinity of the vehicle. Perform the leak test in calm area (low air/wind movement) so that the

leaking refrigerant is not dispersed.

1.

Stop the engine.

2.

Connect a suitable A/C manifold gauge set (SST: J-39183) to the A/C service valves.

3.

Check if the A/C refrigerant pressure is at least 345 kPa (3.52 kg/cm

2

, 50 psi) above 16

°

C (61

°

F). If less

than specification, recover/evacuate and recharge the system with the specified amount of refrigerant.

NOTE:

At temperatures below 16

°

C (61

°

F), leaks may not be detected since the system may not reach 345 kPa

(3.52 kg/cm

2

, 50 psi).

4.

Perform the leak test from the high-pressure side (compressor discharge a to evaporator inlet h) to the

low-pressure side [evaporator drain hose i to shaft seal m(VQ35DE) or n(VK45DE)]. Refer to

. Perform a leak check for the following areas carefully. Clean the component to be

checked and move the leak detected probe completely around the connection/component.

Compressor

Check the fitting of high- and low-pressure flexible hoses, relief valve and shaft seal.

Condenser

Check the fitting of high-pressure flexible hose and pipe.

Liquid tank

Check the fitting of refrigerant pressure sensor.

Service valves

Check all around the service valves. Ensure service valve caps are secured on the service valves (to pre-

vent leaks).

NOTE:

After removing A/C manifold gauge set from service valves, wipe any residue from valves to prevent any

false readings by leak detector.

Cooling unit (Evaporator)

With engine OFF, turn blower fan on “High” for at least 15 seconds to dissipate any refrigerant trace in the

cooling unit. Wait a minimum of 10 minutes accumulation time (refer to the manufacturer’s recommended

procedure for actual wait time) before inserting the leak detector probe into the drain hose.

Keep the probe inserted for at least 10 seconds. Use caution not to contaminate the probe tip with water

or dirt that may be in the drain hose.

5.

If a leak detector detects a leak, verify at least once by blowing compressed air into area of suspected

leak, then repeat check as outlined above.

6.

Do not stop when one leak is found. Continue to check for additional leaks at all system components.

If no leaks are found, perform steps 7 - 10.

7.

Start the engine.

8.

Set the A/C control as follows;

a.

A/C switch: ON

b.

MODE door position: VENT (Ventilation)

c.

Intake door position: Recirculation

d.

Temperature setting: Max. cold

e.

Fan speed: High

9.

Run engine at 1,500 rpm for at least 2 minutes.

10. Stop the engine and perform leak check again following steps 4

through 6 above.

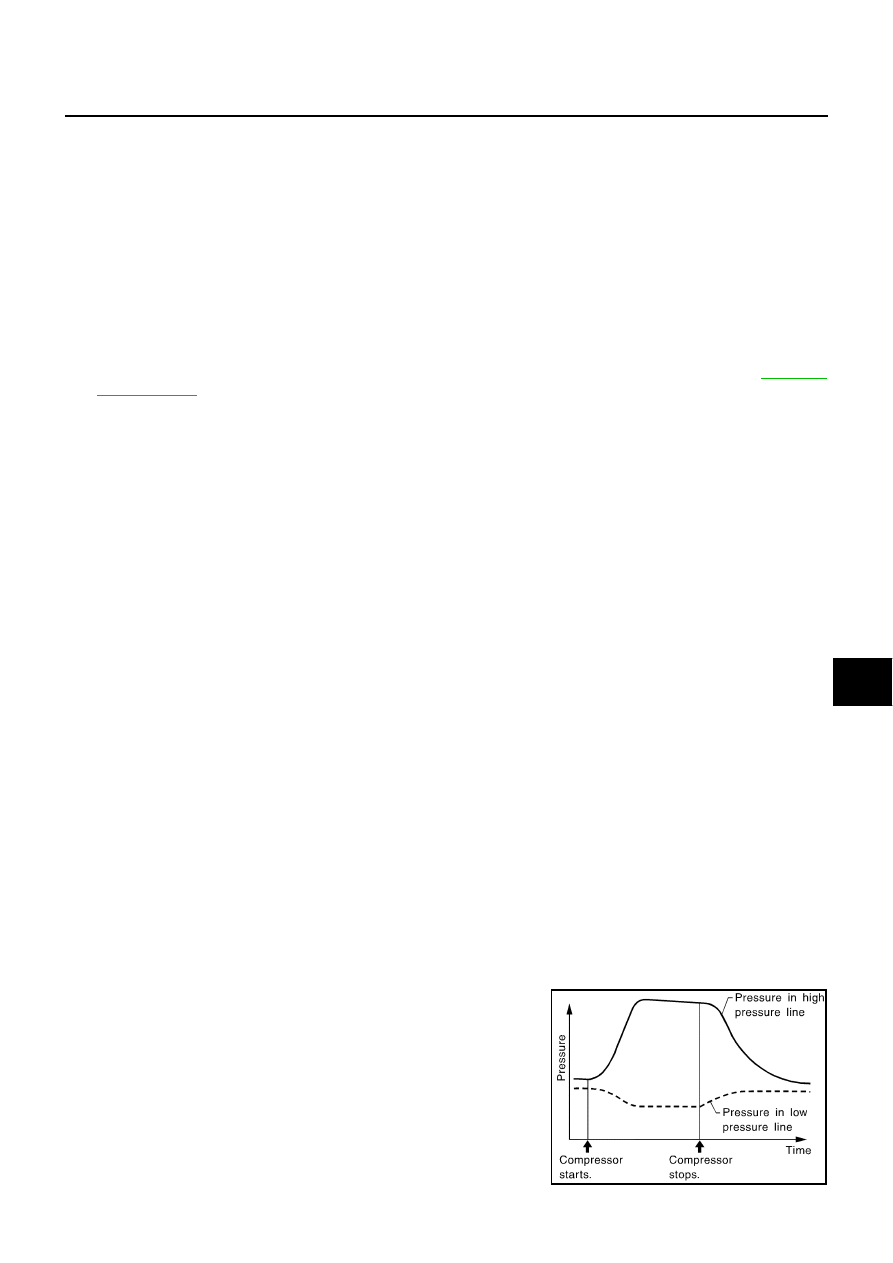

Refrigerant leaks should be checked immediately after stopping

the engine. Begin with the leak detector at the compressor. The

pressure on the high-pressure side will gradually drop after

refrigerant circulation stops and pressure on the low-pressure

side will gradually rise, as shown in the graph. Some leaks are

more easily detected when pressure is high.

SHA839E