Infiniti F50. Manual - part 419

DTC P0340 CMP SENSOR (PHASE)

EC-317

C

D

E

F

G

H

I

J

K

L

M

A

EC

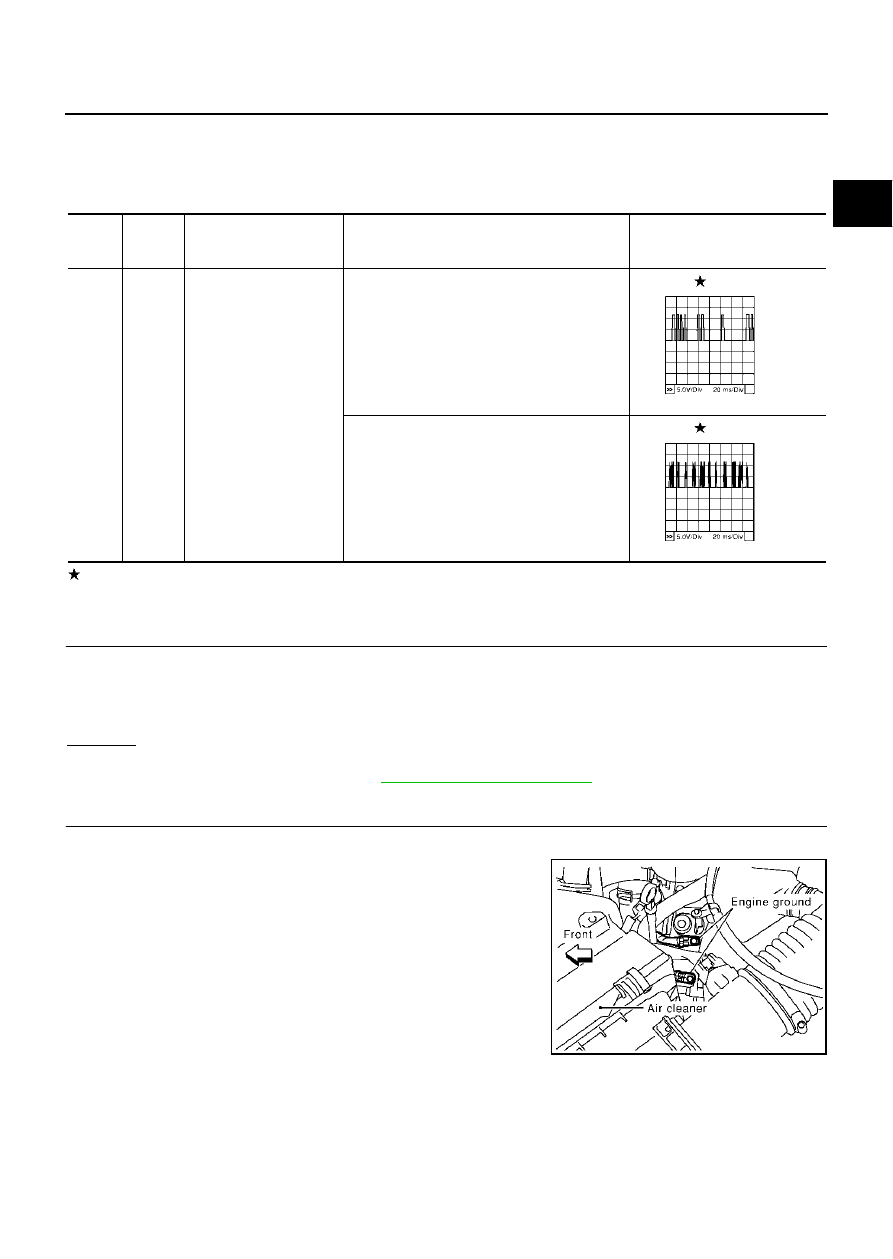

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnostic Procedure

EBS00ME2

1.

CHECK STARTING SYSTEM

Turn ignition switch to “START” position.

Yes or No

Yes

>> GO TO 2.

No

>> Check starting system. (Refer to

2.

RETIGHTEN GROUND SCREWS

1.

Turn ignition switch “OFF”.

2.

Loosen and retighten engine ground screws.

>> GO TO 3.

TER-

MINAL

NO.

WIRE

COLOR

ITEM

CONDITION

DATA (DC Voltage)

84

L/W

Camshaft position sensor

(PHASE)

[Engine is running]

●

Warm-up condition

●

Idle speed

NOTE:

The pulse cycle changes depending on rpm at

idle.

1.0 - 4.0V

[Engine is running]

●

Engine speed is 2,000 rpm.

1.0 - 4.0V

PBIB0056E

PBIB0057E

Does the engine turn over?

Does the starter motor operate?

PBIB0011E