Infiniti F50. Manual - part 420

DTC P0420, P0430 THREE WAY CATALYST FUNCTION

EC-321

C

D

E

F

G

H

I

J

K

L

M

A

EC

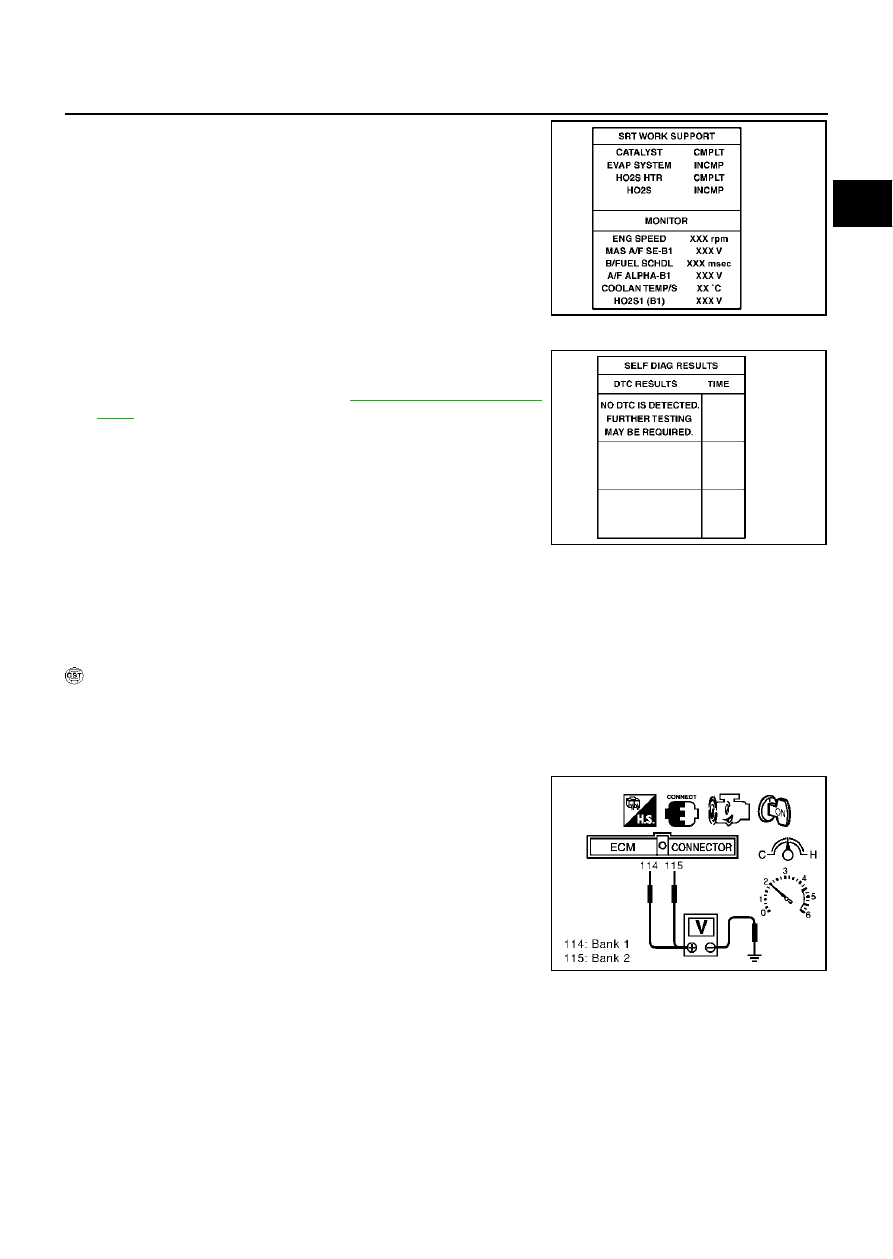

9.

Rev engine up to 2,000 to 3,000 rpm and maintain it until

“INCMP” of “CATALYST” changes to “CMPLT” (It will take

approximately 5 minutes).

If not “CMPLT”, perform the following.

a.

Turn ignition switch “OFF” and leave the vehicle in a cool place

(soak the vehicle).

b.

Turn ignition switch “ON” and select “COOLAN TEMP/S” in

“DATA MONITOR” mode with CONSULT-II.

c.

Start engine and warm it up while monitoring “COOLAN TEMP/

S” indication on CONSULT-II.

d.

When “COOLAN TEMP/S” indication reaches to 70

°

C (158

°

F),

go to step 3.

10. Select “SELF-DIAG RESULTS” mode with CONSULT-II.

11. Confirm that the 1st trip DTC is not detected.

If the 1st trip DTC is detected, go to

.

Overall Function Check

EBS00ME7

Use this procedure to check the overall function of the three way catalyst 1. During this check, a DTC might

not be confirmed.

CAUTION:

Always drive vehicle at a safe speed.

WITH GST

1.

Start engine and warm it up to the normal operating temperature.

2.

Turn ignition switch “OFF” and wait at least 10 seconds.

3.

Start engine and keep the engine speed between 3,500 and 4,000 rpm for one minute under no load.

4.

Let engine idle for one minute.

5.

Set voltmeters probes between ECM terminals 114 [HO2S1

(bank 1) signal], 115 [HO2S1 (bank 2) signal] and engine

ground, and ECM terminals 123 [HO2S2 (bank 1) signal], 124

[HO2S2 (bank 2) signal] and engine ground.

6.

Keep engine speed at 2,000 rpm constant under no load.

SEF941Z

SEF535Z

PBIB0063E