Content .. 1098 1099 1100 1101 ..

Infiniti G37 Coupe. Manual - part 1100

SE-68

< COMPONENT DIAGNOSIS >

TILT&TELESCOPIC SENSOR

TILT&TELESCOPIC SENSOR

Description

INFOID:0000000001694131

Tilt and telescopic sensor detects the position of steering wheel and transmits signals to automatic drive posi-

tioner control unit.

Component Function Check

INFOID:0000000001694132

1.

CHECK TILT AND TELESCOPIC SENSOR FUNCTION

Check tilt and telescopic operation with tilt and telescopic switch.

Is the inspection results normal?

YES

>> Tilt and telescopic sensor is OK.

NO

>> Refer to

Diagnosis Procedure

INFOID:0000000001694133

1.

CHECK TILT AND TELESCOPIC SENSOR SIGNAL

1.

Turn ignition switch ON.

2.

Check voltage between automatic drive positioner control unit harness connector and ground.

Is the inspection result normal?

YES

>> Tilt and telescopic sensor are OK.

NO

>> GO TO 2.

2.

CHECK TILT AND TELESCOPIC SENSOR CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect tilt and telescopic sensor connector and automatic drive positioner control unit connector.

3.

Check continuity between tilt and telescopic sensor harness connector and automatic drive positioner

control unit harness connector.

4.

Check continuity between tilt and telescopic sensor harness connector and ground.

Is the inspection result normal?

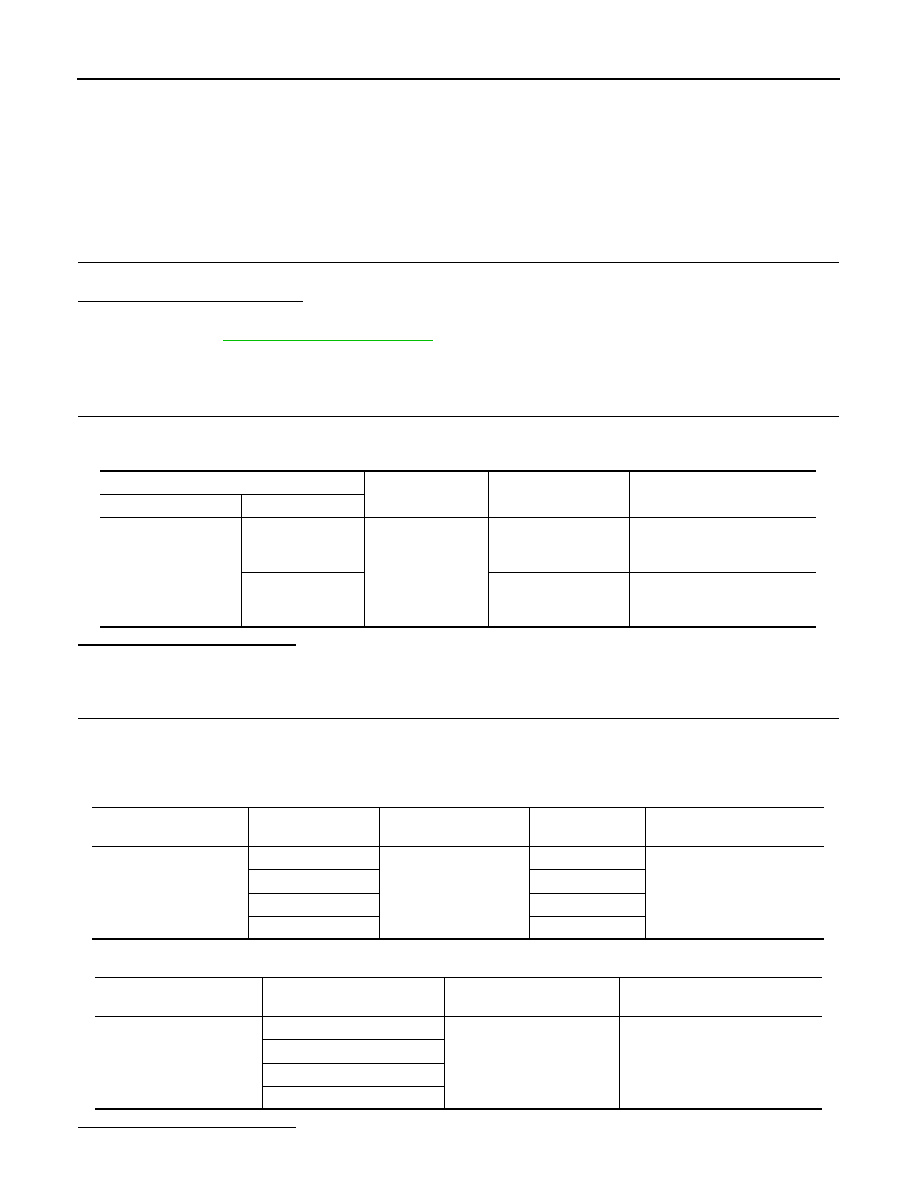

Tilt and telescopic sensor

Ground

Condition

Voltage (V)

(Approx.)

Connector

Terminal

M51

7

Ground

Tilt position

Change between

1.2 (close to top)

3.4 (close to bottom)

23

Telescopic position

Change between

0.8 (close to top)

3.4 (close to bottom)

Tilt and telescopic sensor

connector

Terminal

Automatic drive posi-

tioner control unit

Terminal

Continuity

M48

1

M51, M52

33

Existed

2

23

3

7

4

41

Tilt and telescopic sensor

connector

Terminal

Ground

Continuity

M48

1

Ground

Not existed

2

3

4