Infiniti FX35 / FX45. Manual - part 629

OIL PAN AND OIL STRAINER

EM-33

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

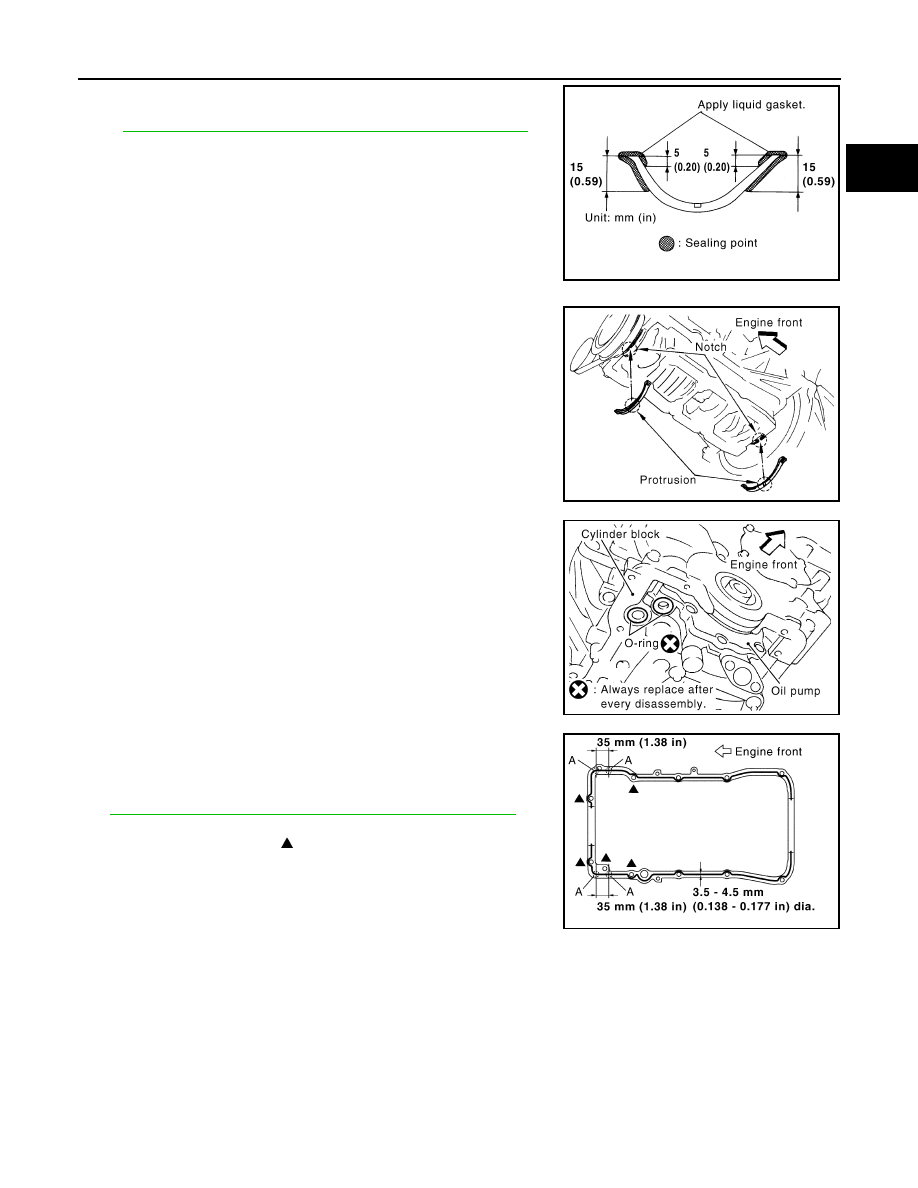

• Apply liquid gasket to oil pan gaskets as shown in the figure.

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-44, "Recommended Chemical Product and Sealant"

.

• To install, align protrusion of oil pan gasket with notches of

front timing chain case and rear oil seal retainer.

• Install oil pan gasket with smaller arc to front timing chain case

side.

c.

Install new O-rings on the bottom of cylinder block and oil pump.

d.

Apply a continuous bead of liquid gasket with the tube presser

(commercial service tool) to the cylinder block mating surface of

oil pan (upper) to a limited portion as shown in the figure.

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-44, "Recommended Chemical Product and Sealant"

CAUTION:

• For bolt holes with marks (5 locations), apply liquid

gasket outside the holes.

• Apply a bead of 4.5 to 5.5 mm (0.177 to 0.217 in) in diame-

ter to area “A”.

• Attaching should be done within 5 minutes after coating.

e.

Install oil pan (upper).

CAUTION:

Install avoiding misalignment of both oil pan gaskets and O-rings.

PBIC2630E

PBIC1145E

PBIC1144E

PBIC2300E