Infiniti FX35 / FX45. Manual - part 630

OIL PAN AND OIL STRAINER

EM-37

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

23. Remove crankshaft position sensor (POS).

CAUTION:

• Handle carefully to avoid dropping and shocks.

• Do not disassemble.

• Do not allow metal powder to adhere to magnetic part at sensor tip.

• Do not place sensors in a location where they are exposed to magnetism.

24. Remove oil pan (lower) as follows:

a.

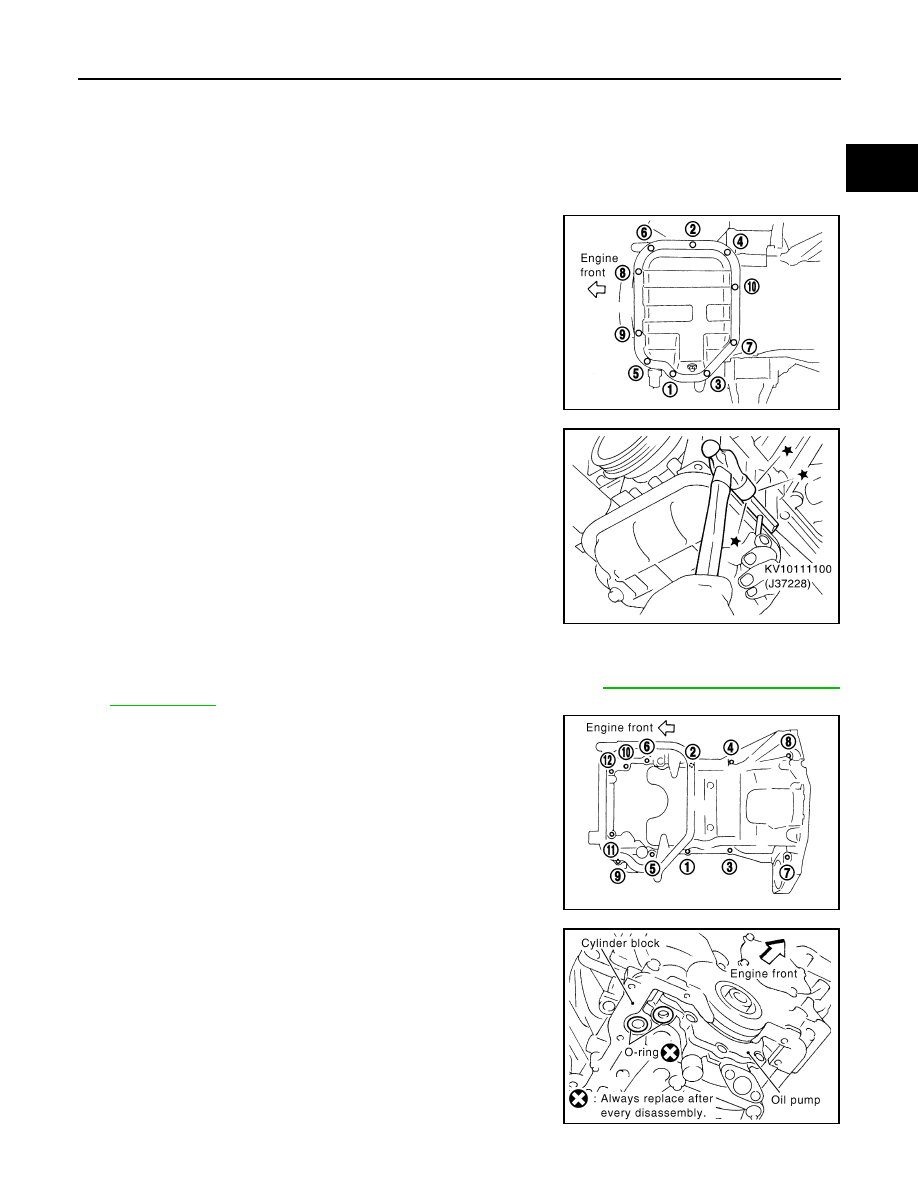

Loosen mounting bolts in reverse order as shown in the figure to

remove.

b.

Insert the seal cutter (SST) between oil pan (upper) and oil pan

(lower).

c.

Slide the seal cutter by tapping on the side of tool with a ham-

mer. Remove oil pan (lower).

CAUTION:

• Be careful not to damage the mating surface.

• Do not insert flat-bladed screwdriver, this will damage the

mating surface.

25. Remove oil strainer.

26. Remove transmission joint bolts which pierce oil pan (upper). Refer to

AT-241, "Removal and Installation

27. Loosen mounting bolts in the reverse order as shown in the fig-

ure with power tool to remove.

• Insert the seal cutter [SST: KV10111100 (J37228)] between oil

pan (upper) and cylinder block. Slide seal cutter by tapping on

the side of tool with a hammer. Remove oil pan (upper).

CAUTION:

• Be careful not to damage the mating surfaces.

• Do not insert a screwdriver, this will damage the mating

surfaces.

28. Remove O-rings from bottom of cylinder block and oil pump.

PBIC0782E

SEM960F

PBIC0783E

PBIC1144E