Infiniti FX35 / FX45. Manual - part 79

AT-244

< SERVICE INFORMATION >

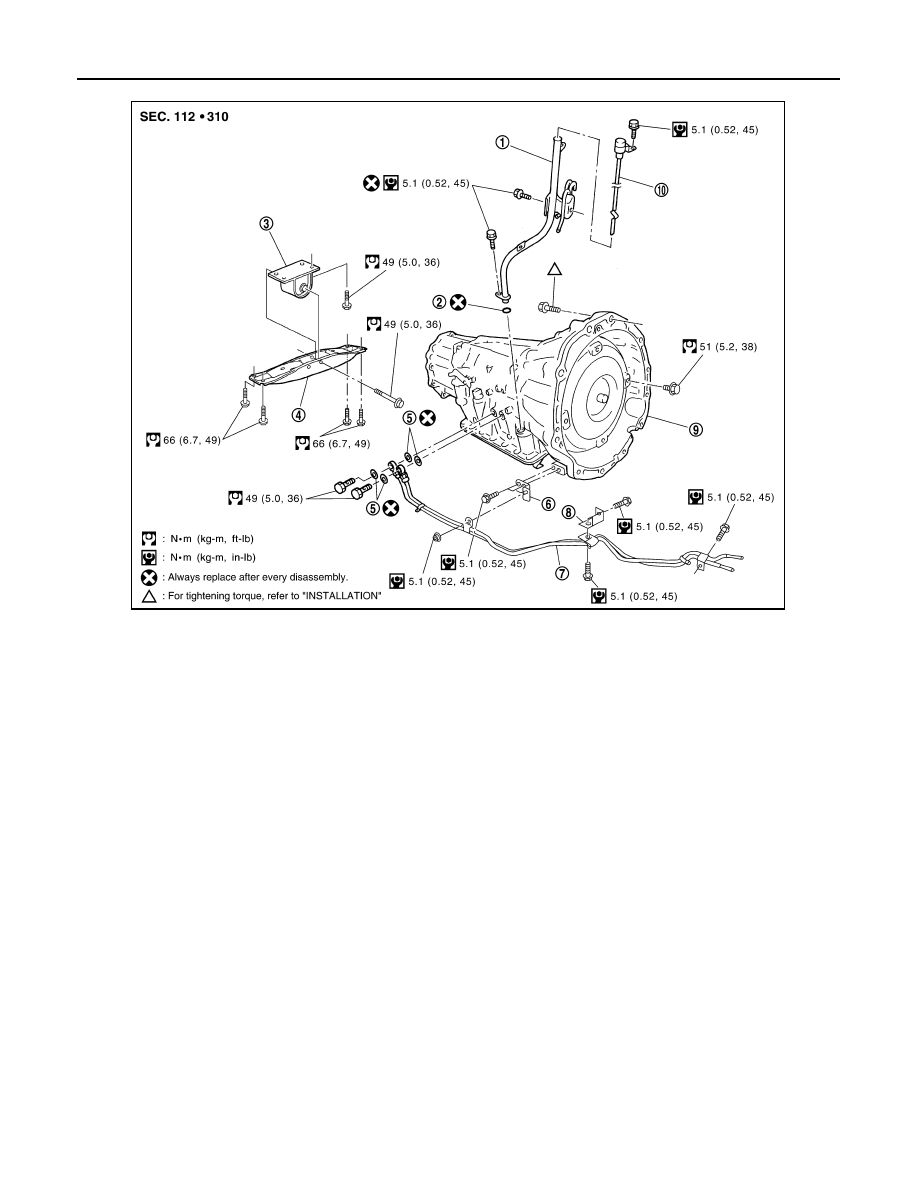

TRANSMISSION ASSEMBLY

COMPONENTS (FOR VK45DE)

1.

A/T fluid charging pipe

2.

O-ring

3.

Engine mounting insulator (rear)

4.

Rear engine mounting member

5.

Copper washer

6.

Bracket

7.

Fluid cooler tube

8.

Bracket

9.

A/T assembly

10. A/T fluid level gauge

SCIA6425E